En-9

6.2. Wiring method

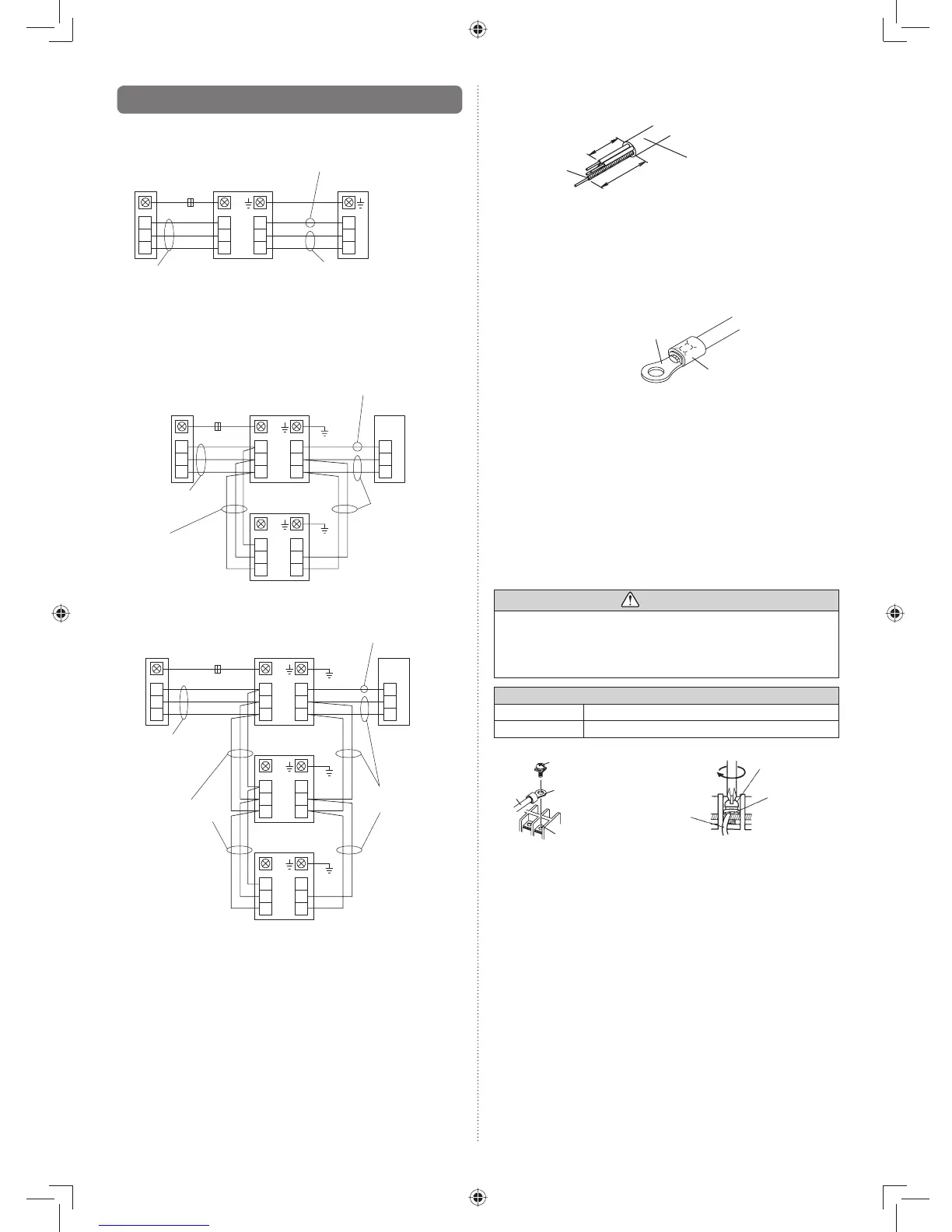

6.2.1. Connection diagrams

(Standard pair)

Indoor unit

B

W

R

3

2

1

3

2

1

3

2

1

Outdoor unit

Wired remote

controller

Black

White

Red

*

Power supply cable

Transmission cable

Remote controller cable

*Ground the remote controller if it has a ground wire.•

Wired remote controller is recommended using simultaneous

twin or triple connection.

(Simultaneous twin)

Indoor unit

(Master)

Indoor unit

(Slave)

B

W

R

3

2

1

3

2

1

3

2

1

Outdoor unit

Wired remote

controller

3

2

1

3

2

1

Black

White

Red

*

Power supply

cable

Bus wire

(Local purchase)

Transmission cable

Remote controller

cable

(Simultaneous triple)

Indoor unit

(Master)

Indoor unit

(Slave)

B

W

R

3

2

1

3

2

1

3

2

1

Outdoor unit

Wired remote

controller

3

2

1

3

2

1

Indoor unit

(Slave)

3

2

1

3

2

1

Black

White

Red

*

Power supply

cable

Bus wire

(Local purchase)

Transmission

cable

Remote controller

cable

Connect the remote controller wires to the master unit.•

*Ground the remote controller if it has a ground wire.•

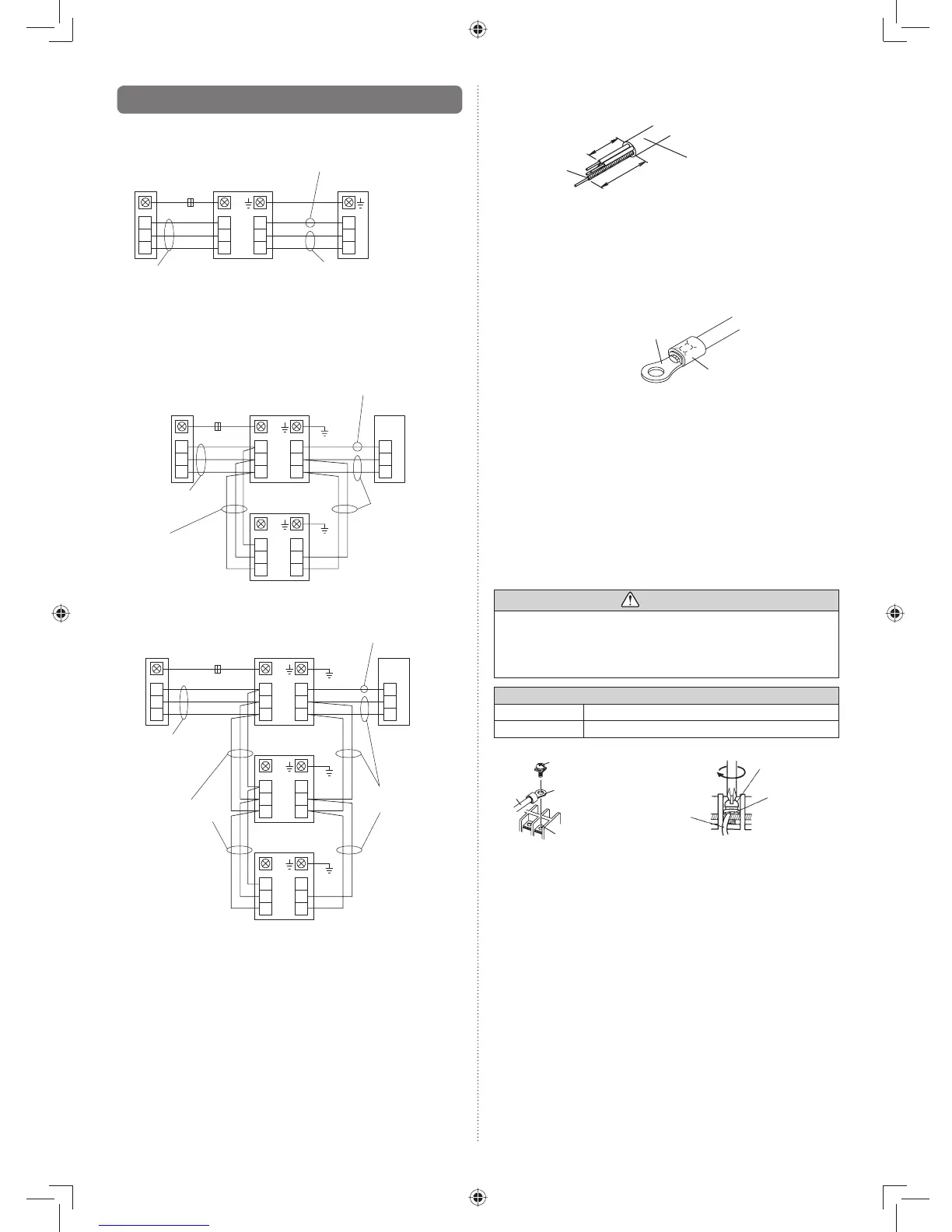

6.2.2. Connection cable preparation

Keep the earth wire longer than the other wires.•

Power suppl

How to connect wiring to the terminals.

(For strand wiring)

Use crimp-type terminals with insulating sleeves as shown (1)

in the fi gure below to connect to the terminal block.

Securely crimp the crimp-type terminals to the wires using (2)

an appropriate tool so that the wires do not come loose.

Sleeve

Crimp-type terminal

Use the specifi ed wires, connect them securely, and fasten (3)

them so that there is no stress placed on the terminals.

Use an appropriate screwdriver to tighten the terminal (4)

screws.

Do not use a screwdriver that is too small, otherwise, the

screw heads may be damaged and prevent the screws

from being properly tightened.

Do not tighten the terminal screws too much, otherwise, (5)

the screws may break.

See the table below for the terminal screw tightening (6)

torques.

WARNING

Use crimp-type terminals and tighten the terminal screws •

to the specifi ed torques, otherwise, abnormal overheat-

ing may be produced and possibly cause heavy damage

inside the unit.

Tightening torque [N·m (kgf·cm)]

M4 screw 1.2 to 1.8 (12 to 18)

M5 screw 2.0 to 3.0 (20 to 30)

Wire

Screw with

special washer

Crimp-type terminal

Terminal blocks

Wire

Screw with

special washe

Loading...

Loading...