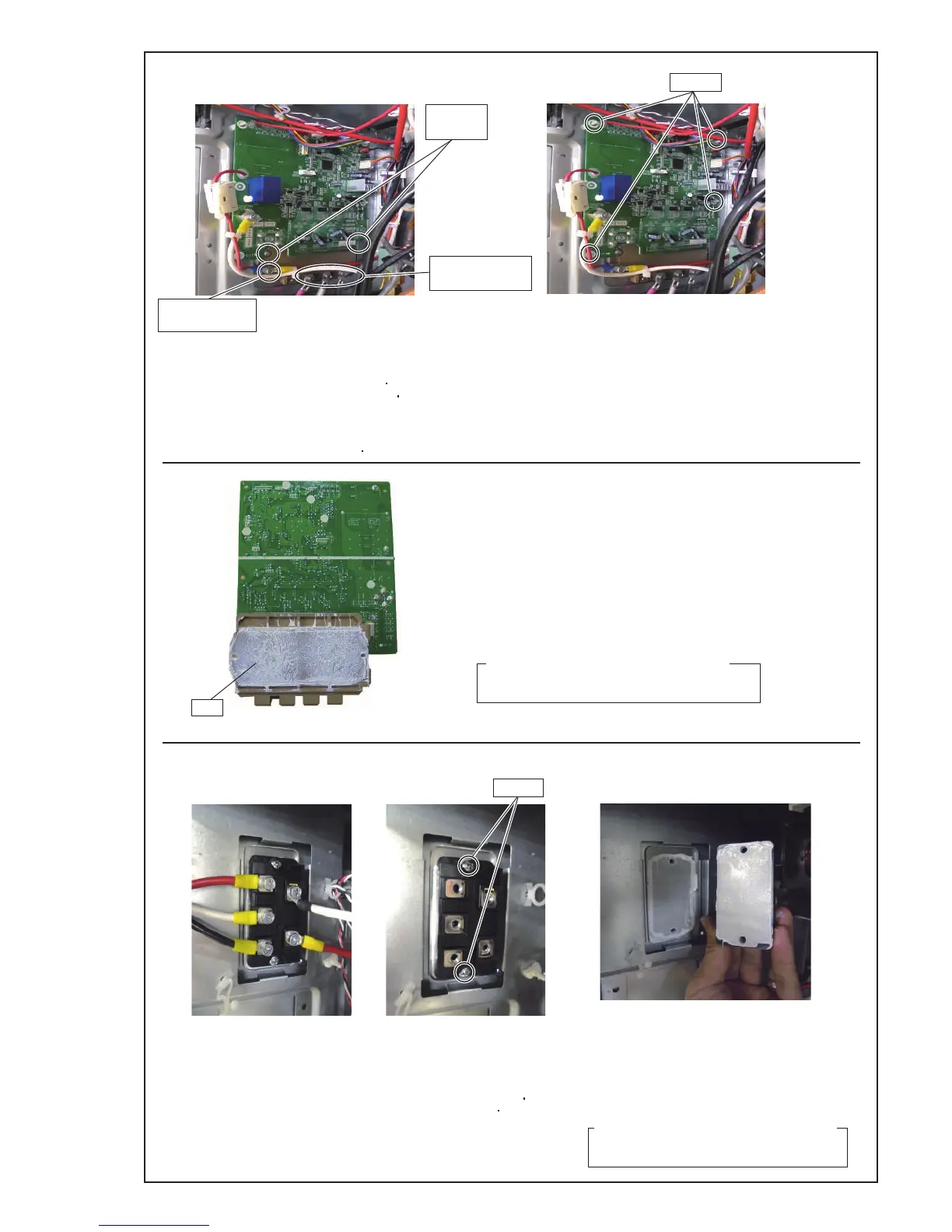

Remove the 4 mounting screws.

Remove the connectors and spacers.

Remove the wires. Remove the screws.

06-04

Screw

(To Power PCB)

Screws

(For IPM)

Spacers

Screws

5-2. INVERTER PCB removal

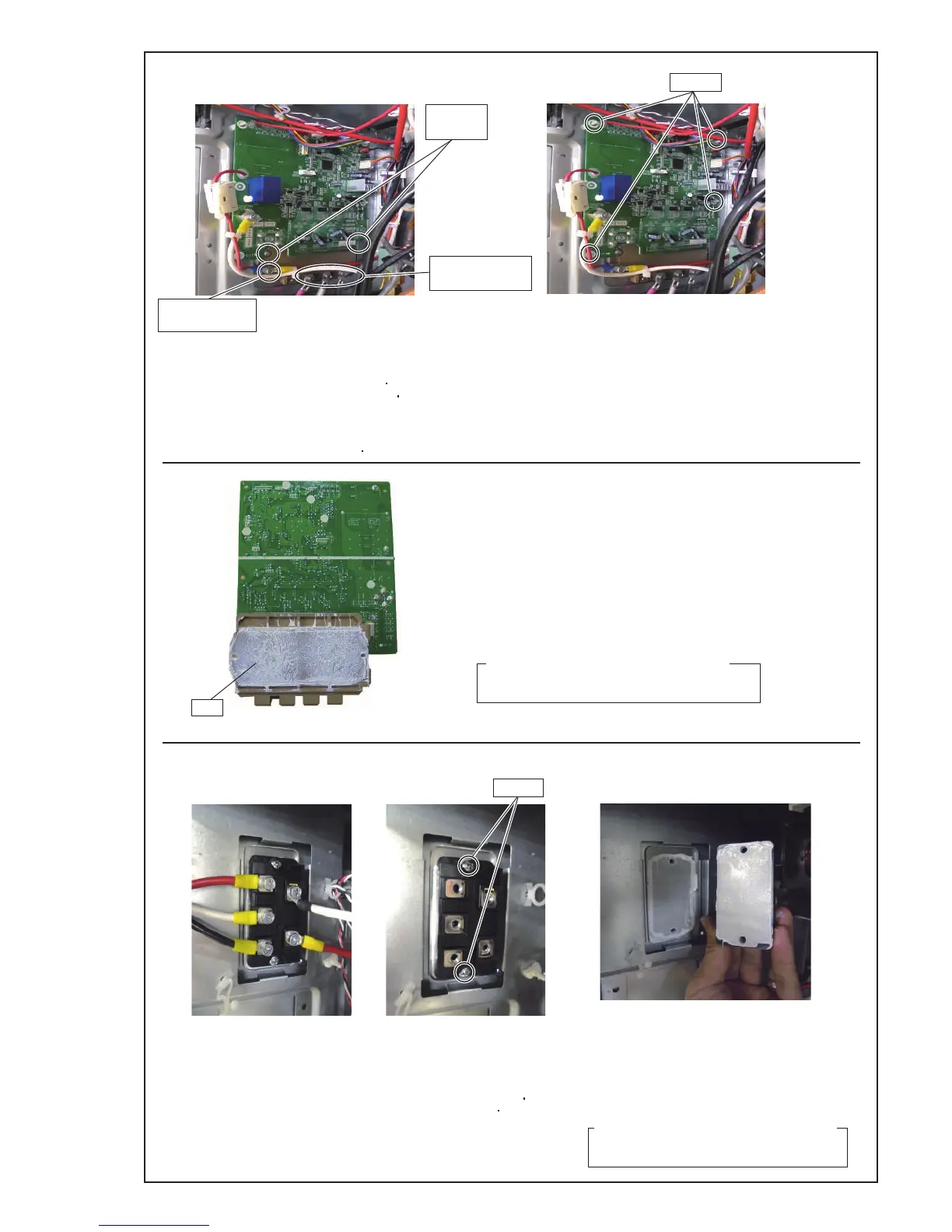

5-3. DIODE BRIDGE removal

Spread the heat transfer compound on IPM

when you exchange INVERTER PCB by the repair.

For screws of IPM.

Note the tightening torque at the installation.

Temporary tightening : 0.2 to 0.4N m

Final tightening : 0.98 to 1.47N m

Note at the installation.

1. Remove the old heat transfer compound as possible from IPM and

Diode Bridges when you exchange INVERTER PCB by the repair.

2. Spread the heat transfer c

o

mpound evenly on IPM and Diode Bridges.

3. Prevent foreign matter from attaching to the surface of IPM and Diode Bridges.

Note at the installation.

1. Remove the old heat transfer compound as possible from

D.B. when you

exchange ACTPM by the repair.

2. Spread the heat transfer compound evenly on D.B. .

3. Prevent foreign matter from attaching to the surface of D.B. .

For screws of D.B. .

- Manufacturer : Shin-Etsu Chemical Co.,Ltd

- Grade : G746

Specifications for the heat transfer compound

Spread the heat transfer compound on D.B.

when you exchange D.B. by the repair.

- Manufacturer : Shin-Etsu Chemical Co.,Ltd

- Grade : G746

Specifications for the heat transfer compound

IPM

Screws

(For Comp. Wire)

Note the tightening torque at the installation.

Tightening torque is as follows.

- Final tightening : 1.4 to 1.6 N m

For screws of Comp. Wire.

-

-

Note the tightening torque at the installation.

Tightening torque is as follows.

- Temporary tightening : 0.6 +0.1N m

- Final tightening : 2.4 +0.1N m

Loading...

Loading...