Gator Automatic Butt Fusion Range

Operating Manual

EDOI6922 Page 28 of 44 Issue 02

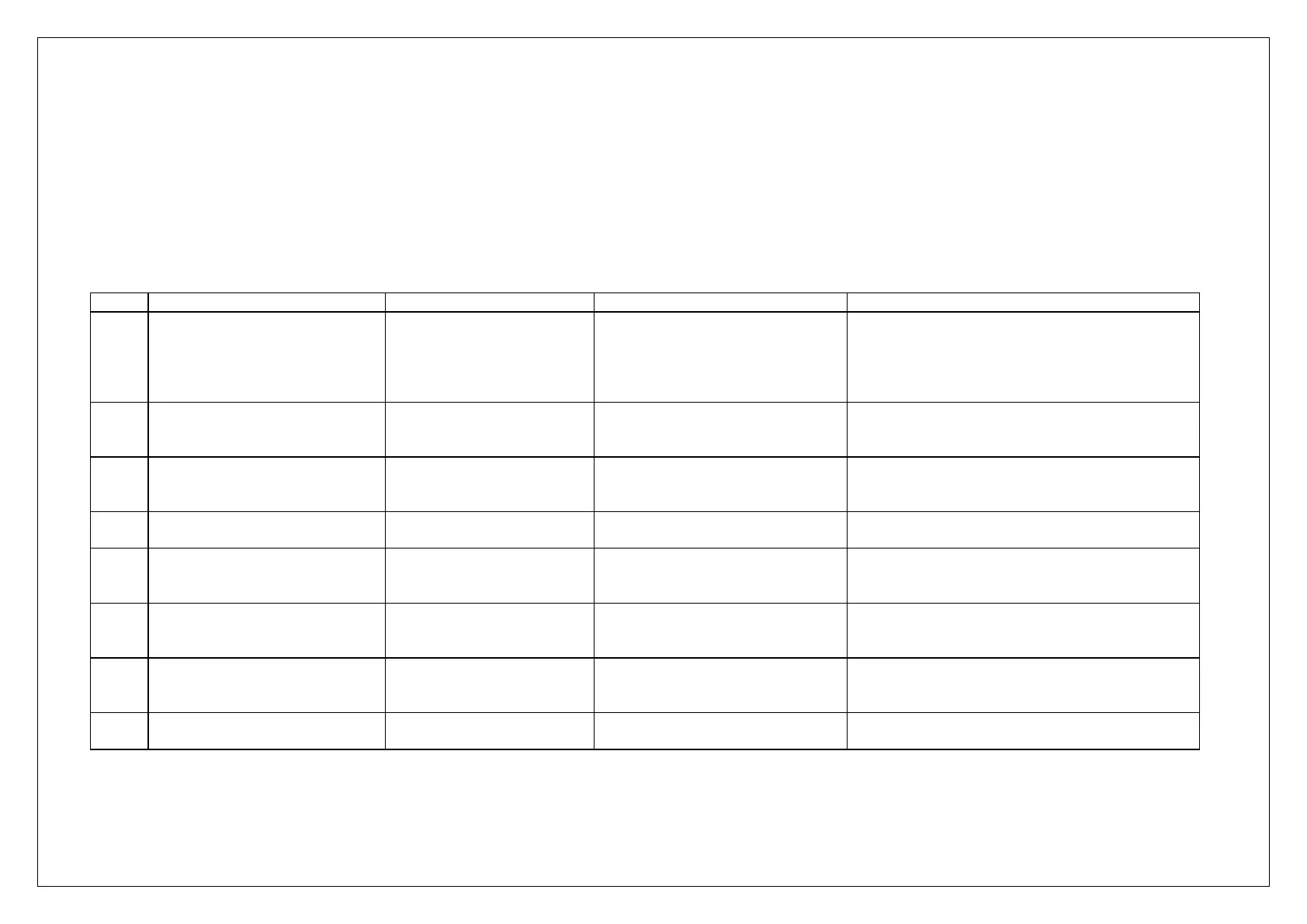

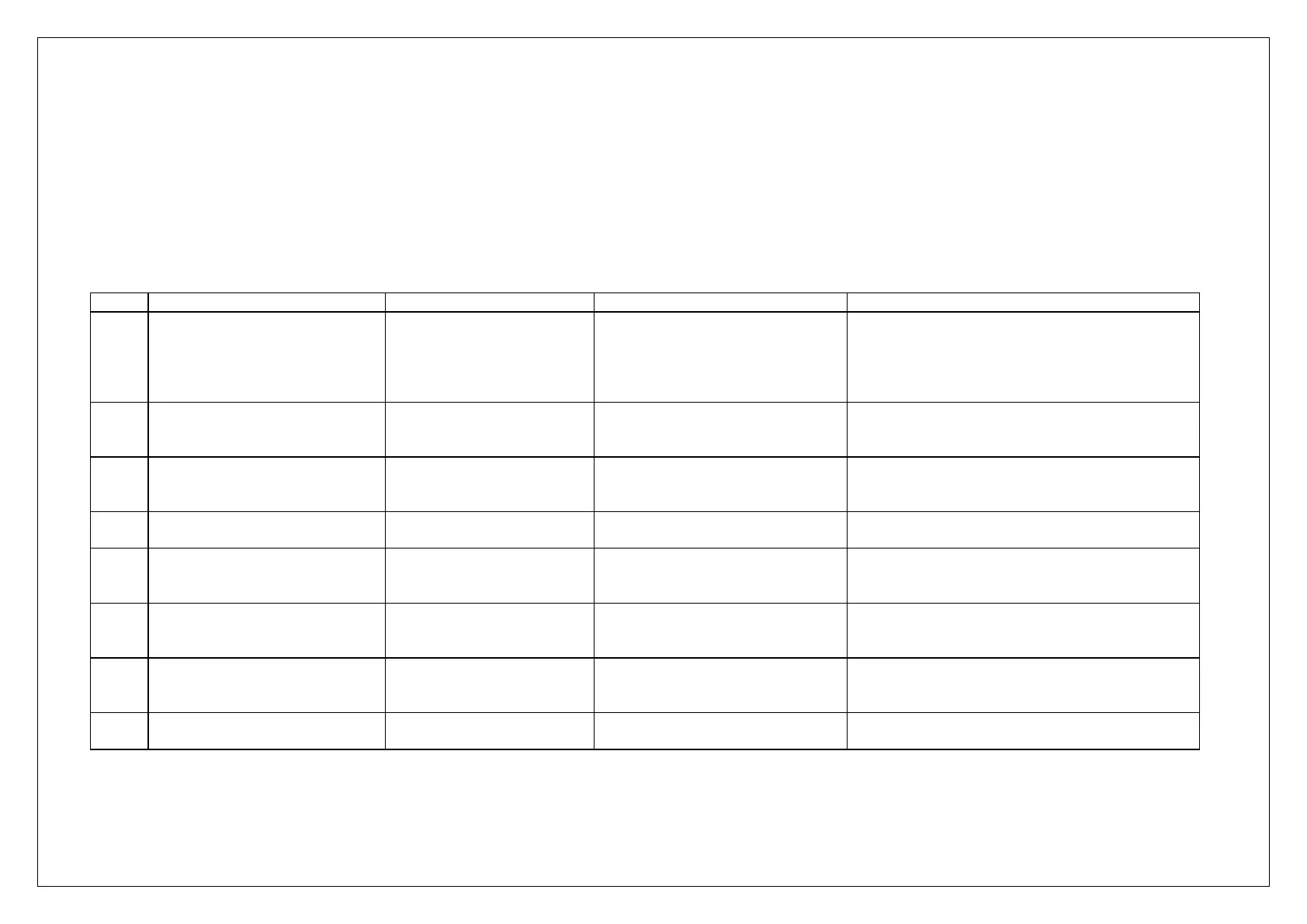

12 Error messages

During the welding cycle, the controller monitors the system for problems which could potentially result in poor joints. In the event of

such a problem, or if an unexpected event occurs, a message is issued indicating its nature. The following shows the failure modes,

likely causes and remedies.

The error message numbers have been retained from previous ABF products for consistency. Some of the old error messages have

been removed since they no longer apply. Also included in the chart are other general faults.

Trimmer has not reached

end point in allowed time

Blunt blades

No blades fitted

Trimmings are clogging the

blades

Poorly set blades

Sharpen or replace the blades.

Fit blades.

Press red button, open the machine and remove

swarf from blades.

Adjust the blade settings.

Unexpected clamp

movement was detected

during the CHECK stage

Clamps or liners were not secure

Press red button, open the machine, reset the

pipes, re-secure the pipes ensuring they are

fixed firmly, then re-trim and re-check.

Bead not formed as

expected in the allowed

time

Wrong pipe parameters were

selected

Press red button. Select the correct pipe type;

start joint again.

Excessive heater plate

removal time experienced

Heater stuck in non-up position

Heater up switch faulty

Check heater and machine for obstructions.

Contact supplier.

Excessive heater plate

removal time experienced

Heater not ejected quickly enough

Machine movement obstructed

Check heater and machine for obstructions.

Ensure pipes are well supported throughout the

welding process.

The heater plate has been

detected at an

inappropriate stage

Press the machine open key to eject the heater

and then follow the screen prompts.

The trimmer has been

detected at an

inappropriate stage

Trimmer positioned in error

Remove the trimmer and follow the screen

prompts.

The measured drag

exceeds 60 bar

Support the pipes using pipe support rollers

Loading...

Loading...