3

Remove crimper, back-up ring, no notched die cone

(notched die cone sold separately PN 7482-0297),

die magnet, hose assembly, mounting bracket with

bolt, jar of Molykote “G” grease, operating manual,

crimp data book and crimp decals from shipping

carton. Locate serial number on base plate in front

of left post and record on Page 1. Be sure to fill out

the crimper registration card. (By completing the

card and returning it to Gates, you will receive crimp

data updates and full warranty coverage.) Remove

pump, breather cap and operating manual from its

shipping carton.

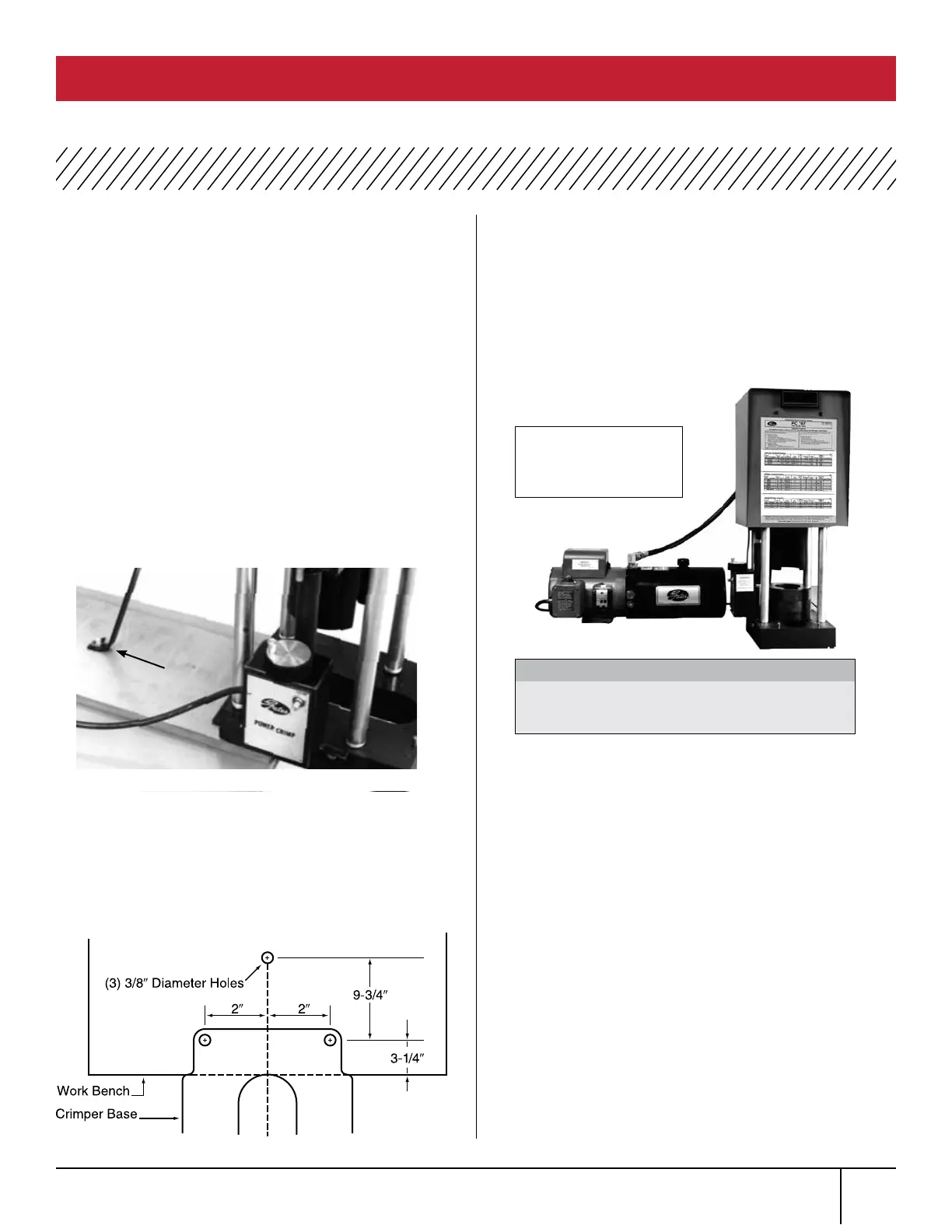

Mount crimper so it overhangs a workbench (as

shown in Photo 1). The back of the cutout (in the

base plate) should be in line with front of bench.

The bench should be 37” to 42” high, stable and of

sturdy construction.

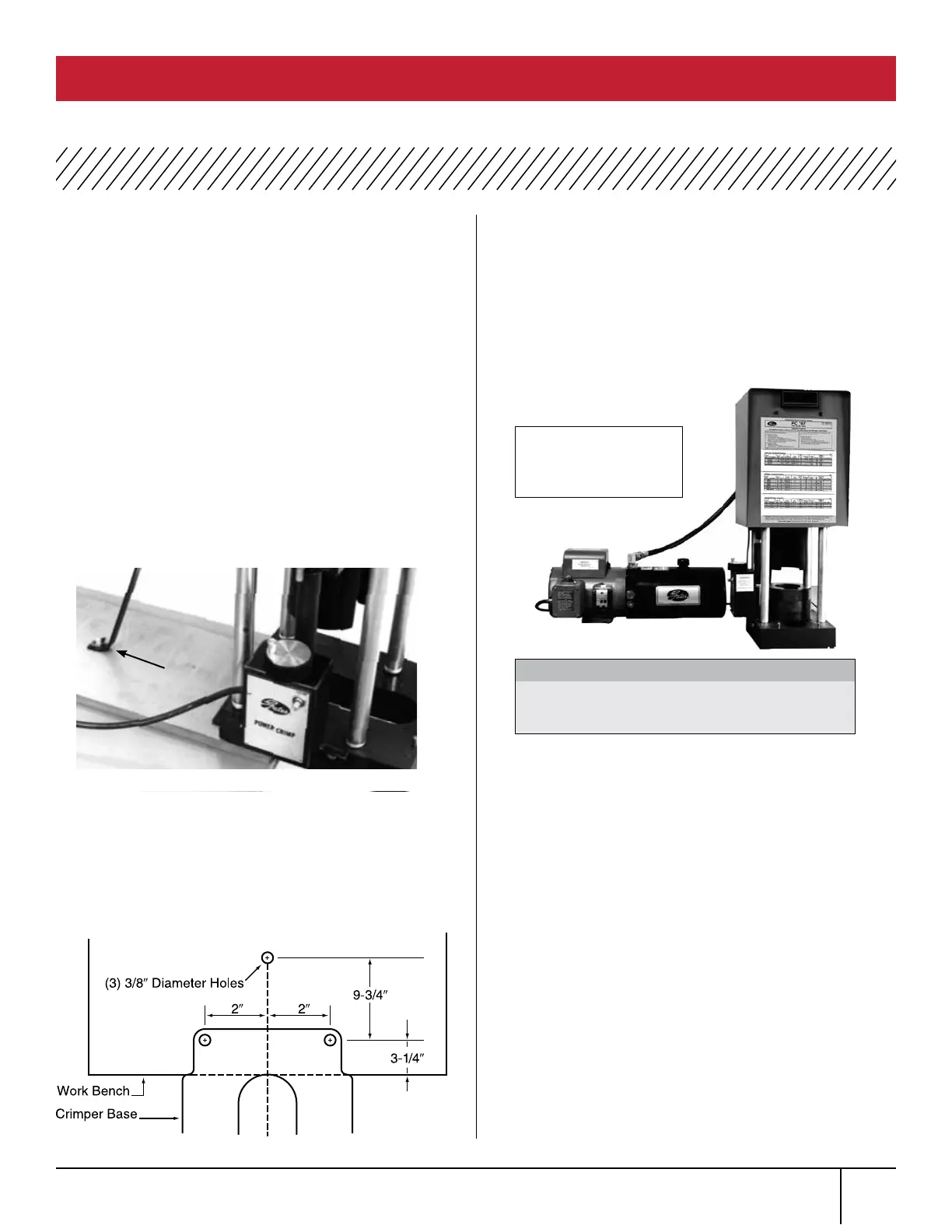

Drill three 3/8” diameter holes as shown in

Illustration 1. Connect the mounting bracket to top

rear of crimper and to the hole farthest from edge

of workbench. Further secure crimper to workbench

using the two remaining holes.

When crimper is secured to the workbench, connect

hose assembly between crimper and pump.

Connect receptacle on short cord of pump to plug

on cord of switch box of the crimper. If plug and

receptacle do not match, do not try to connect.

Differences in the plug and receptacle indicate

the pump and crimper have different voltages and

should not be operated.

Remove plug from top of pump reservoir and replace

with breather cap provided. Check that hydraulic oil

is within 1/2” of bottom of plug opening. If needed,

add Dextron II ATF or equivalent to reservoir.

Verify that switch on pump electrical box is in “OFF”

position. Connect pump power cord to a 15 amp

(minimum) rated electrical circuit.

Move switch on pump electrical box to “ON” position.

This will provide power to the pump and crimper.

Turn knob on top of crimper switch box to get a

setting of 2.00 on the readout. Cycle crimper at

least 5 times to bleed air from cylinder and

hydraulic system.

Peel and position crimp

decal on the shroud

according to your

preference.

Crimper and pump voltage must be the same

or digital readout will be damaged.

WARNING:

ILLUSTRATION 1

PHOTO 1

Mounting

Bracket

SETUP

PC 707 CRIMPER SAFETY AND OPERATING MANUAL

1.

2.

3.

4.

5.

6.

7.

8.

9.

Loading...

Loading...