9

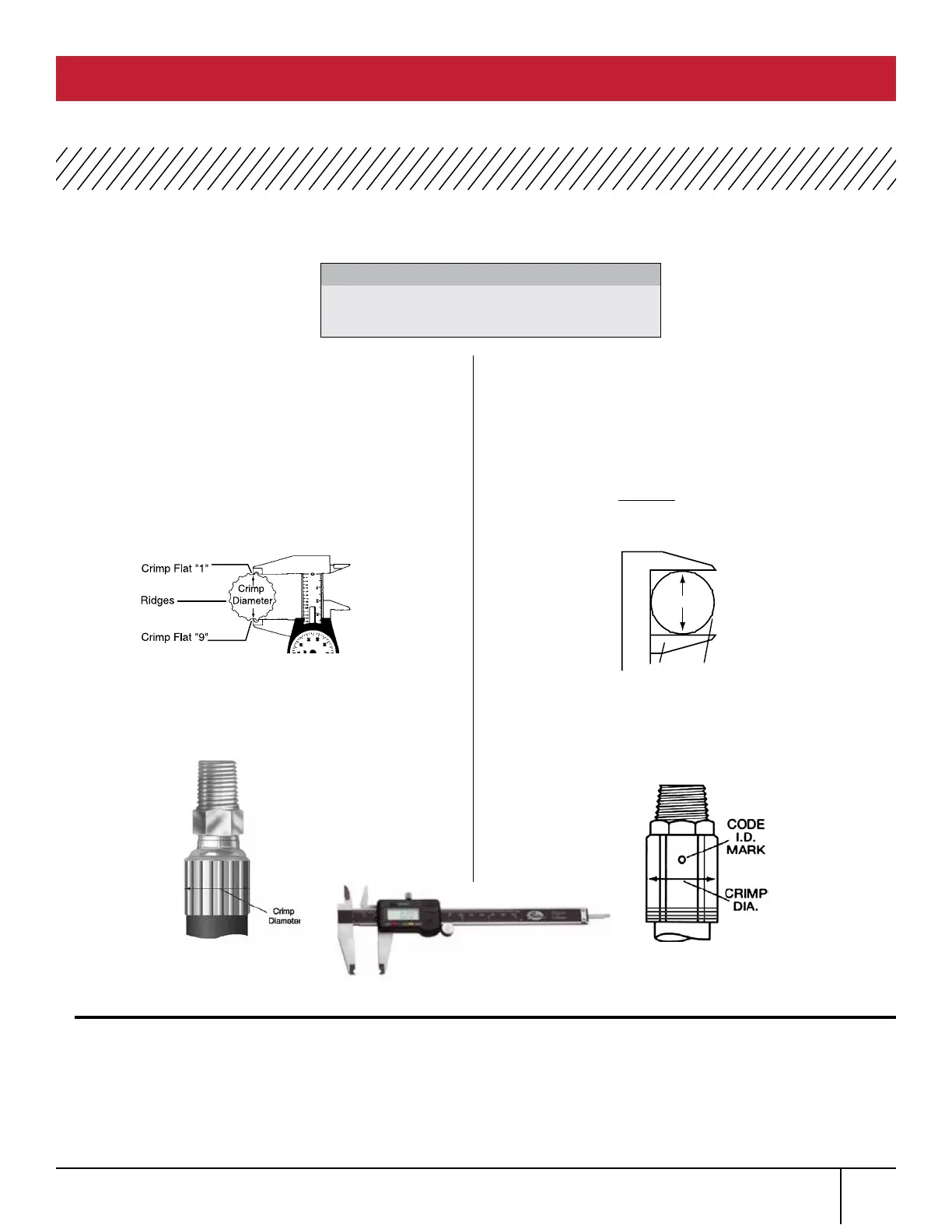

SKETCH 2

DO NOT measure on top of

part number stamps.

NOTE:

TO PROPERLY MEASURE A CRIMP DIAMETER:

FIG. 1

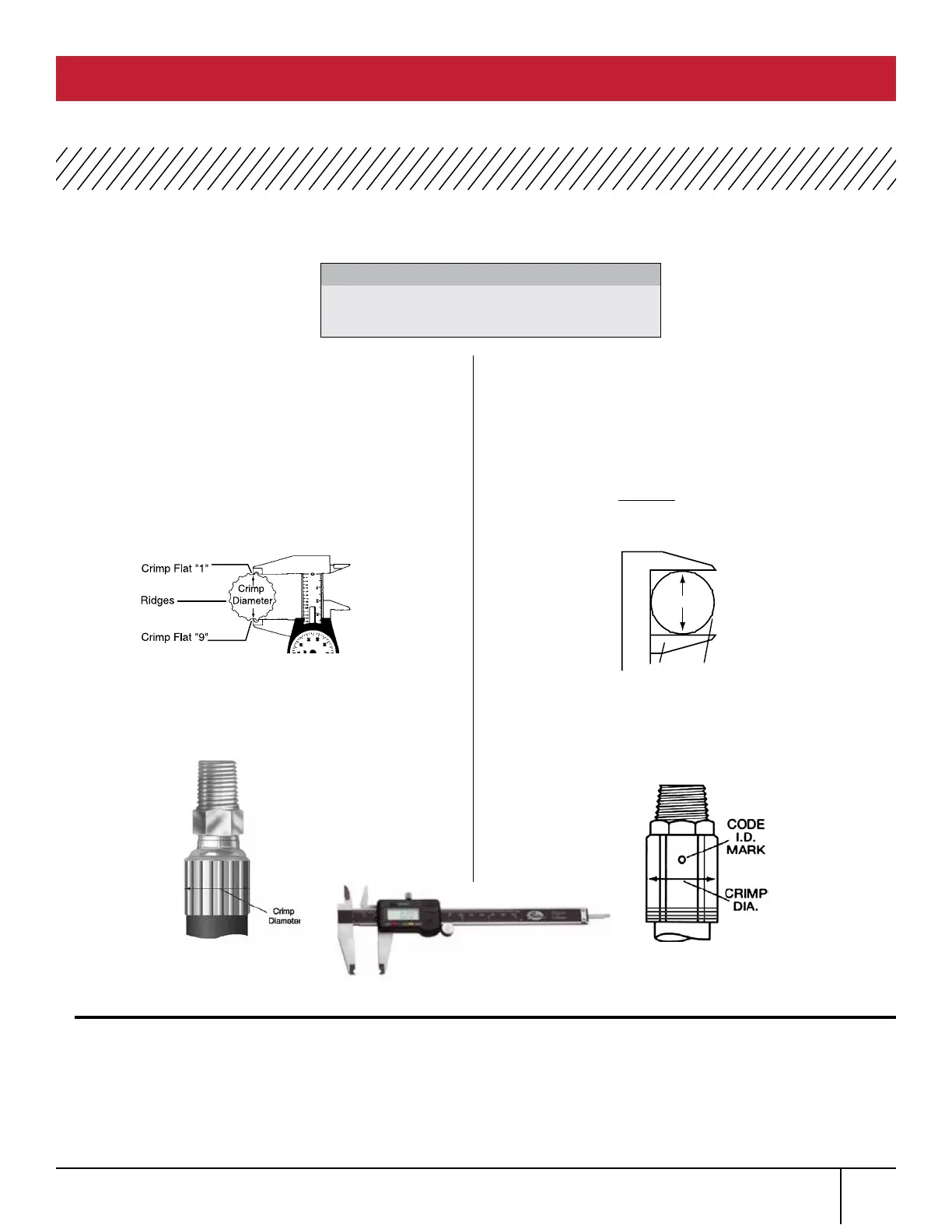

SKETCH 1

FIG. 2

WHEN USING 21 AND 22 DIES

Using Gates dial calipers (Product No.

7369-0322, Part No. 78215) measure halfway

between ridges (Fig. 1). To be sure crimp diameter

is being properly measured, mark a crimp flat.

Beginning with that flat, count 9 flats to get the

diameter. Be sure caliper blades DO NOT touch

ridges. (See Photo 3.)

Measure halfway between the ends of crimped

portion of the ferrule (Fig. 2).

Should actual crimp diameter not be within

recommended crimp tolerance, check calibration

of the machine and recalibrate. If the machine is

properly calibrated, you may need to make a slight

adjustment to the digital readout.

WHEN NOT USING 21

AND 22 DIES

Using Gates dial calipers (Product No. 7369-0322,

Part No. 78215) which are notched to clear ridges,

measure halfway between ridges (Sketch 1). Be sure

caliper fingers DO NOT touch ridges or part number

stamps. (See Photo 3.)

Measure halfway down the crimped portion of the

ferrule (Sketch 2).

To obtain a smaller crimp diameter, change digital

read out setting to smaller number. To get a larger

crimp diameter, change digital readout setting to a

larger number. Changing digital readout number by

.05 will change crimp diameter .001”. Record new

setting on your crimp data chart for future reference.

MEASURING CRIMP DIAMETER

PC 707 CRIMPER SAFETY AND OPERATING MANUAL

1.

2.

1.

3.

2.

4.

PHOTO 3

Loading...

Loading...