8

When you hear pump shut off, release switch and

the ram will move up.

Move die cone and backup ring unit all the way

forward. Remove assembly by lifting the die cone.

Measure crimp diameter. (See Page 9).

Check the crimp data chart for correct

crimp diameter.

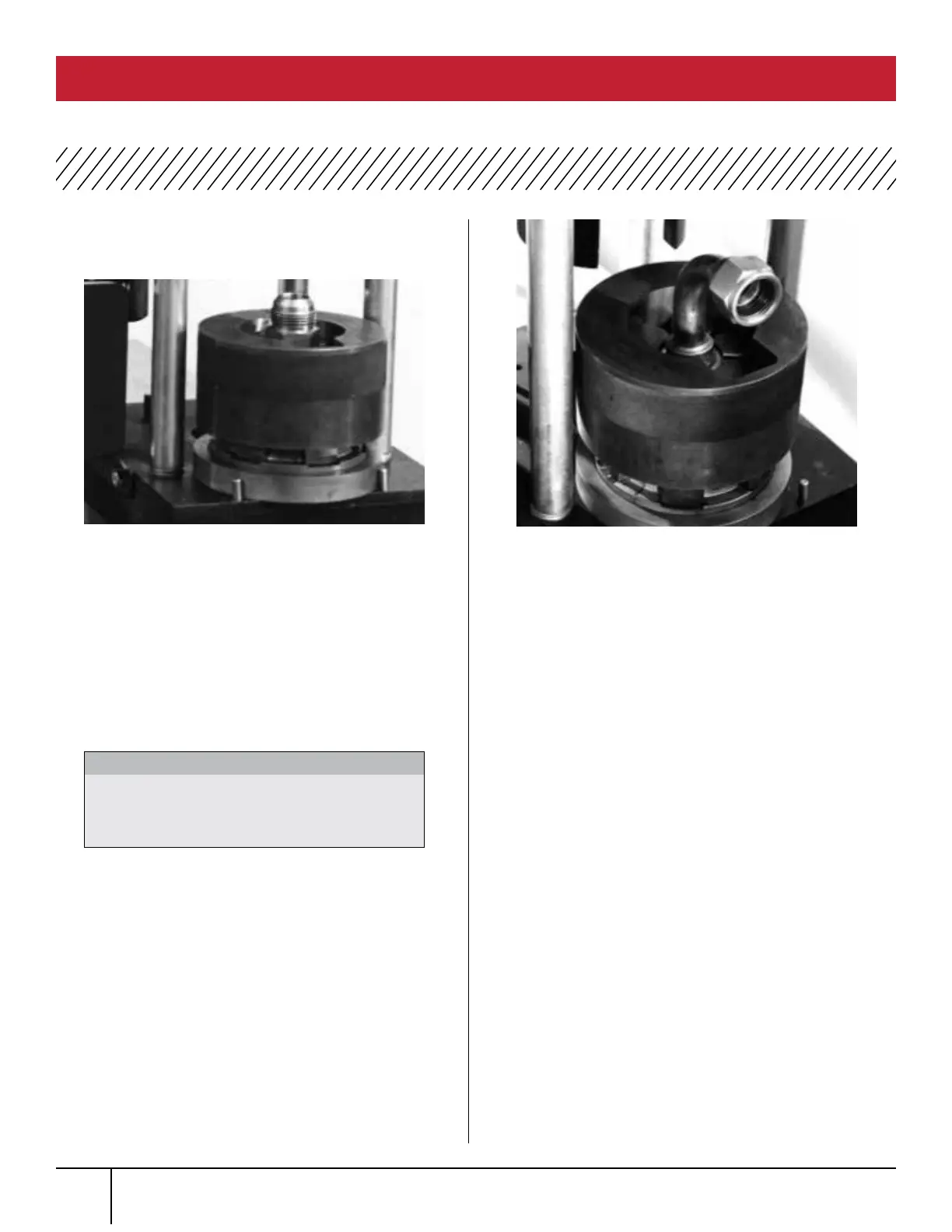

USING THE OPTIONAL

NOTCHED CONE

Position thread end of coupling into the die cone

notch, which must be towards the front of the

crimper.

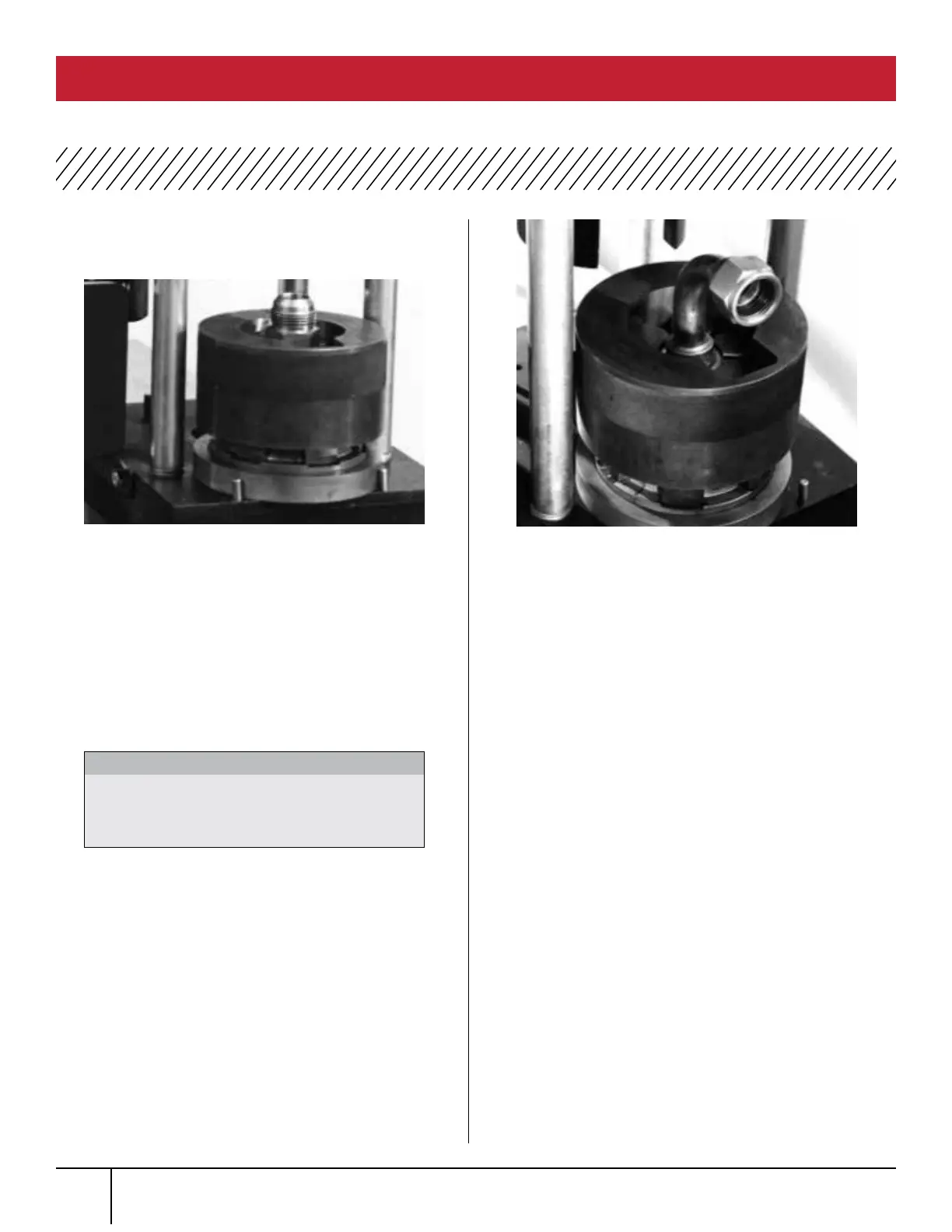

When crimping bent tube couplings, use the same

procedure as crimping straight end couplings.

Keep thread end of bent tube forward to clear

notch in cone.

To crimp a 45° or 90° block type coupling, follow

the same procedure used for the bent tube.

Your measured crimp diameter MUST be in

tolerance range as listed in eCrimp or the

Crimp Data Manual.

WARNING:

OPERATING INSTRUCTIONS (continued)

PC 707 CRIMPER SAFETY AND OPERATING MANUAL

13.

14.

15.

16.

1.

2.

3.

Loading...

Loading...