7.3.1 Harmonics Emission Requirements

Equipment connected to the public supply network:

Options Definition

1 IEC/EN 61000-3-2 Class A for 3-phase balanced

equipment (for professional equipment only up to 1

kW total power).

2 IEC/EN 61000-3-12 Equipment 16A-75A and profes-

sional equipment as from 1 kW up to 16A phase

current.

Table 7.7 Connected Equipment

7.3.2 Harmonics Test Results (Emission)

Power sizes from 0.75 kW and up to 18.5 kW in 200 V and

up to 90 kW in 460 V complies with IEC/EN 61000-3-12,

Table 4. Power sizes 110 - 450 kW in 460 V also complies

with IEC/EN 61000-3-12 even though not required because

currents are above 75 A.

Provided that the short-circuit power of the supply S

sc

is

greater than or equal to:

S

SC

=

3 ×

R

SCE

×

U

mains

×

I

equ

=

3 × 120 × 400 ×

I

equ

at the interface point between the user’s supply and the

public system (R

sce

).

It is the responsibility of the installer or user of the

equipment to ensure, by consultation with the distribution

network operator if necessary, that the equipment is

connected only to a supply with a short-circuit power S

sc

greater than or equal to specified above.

Other power sizes can be connected to the public supply

network by consultation with the distribution network

operator.

Compliance with various system level guidelines:

The harmonic current data in the table are given in

accordance with IEC/EN61000-3-12 with reference to the

Power Drive Systems product standard. They may be used

as the basis for calculation of the harmonic currents'

influence on the power supply system and for the

documentation of compliance with relevant regional

guidelines: IEEE 519 -1992; G5/4.

7.4 Galvanic Isolation (PELV)

7.4.1 PELV - Protective Extra Low Voltage

PELV offers protection by way of extra low voltage.

Protection against electric shock is ensured when the

electrical supply is of the PELV type and the installation is

made as described in local/national regulations on PELV

supplies.

All control terminals and relay terminals 01-03/04-06

comply with PELV (Protective Extra Low Voltage) (Does not

apply to grounded Delta leg above 400 V).

Galvanic (ensured) isolation is obtained by fulfilling

requirements for higher isolation and by providing the

relevant creapage/clearance distances. These requirements

are described in the EN 61800-5-1 standard.

The components that make up the electrical isolation, as

described below, also comply with the requirements for

higher isolation and the relevant test as described in EN

61800-5-1.

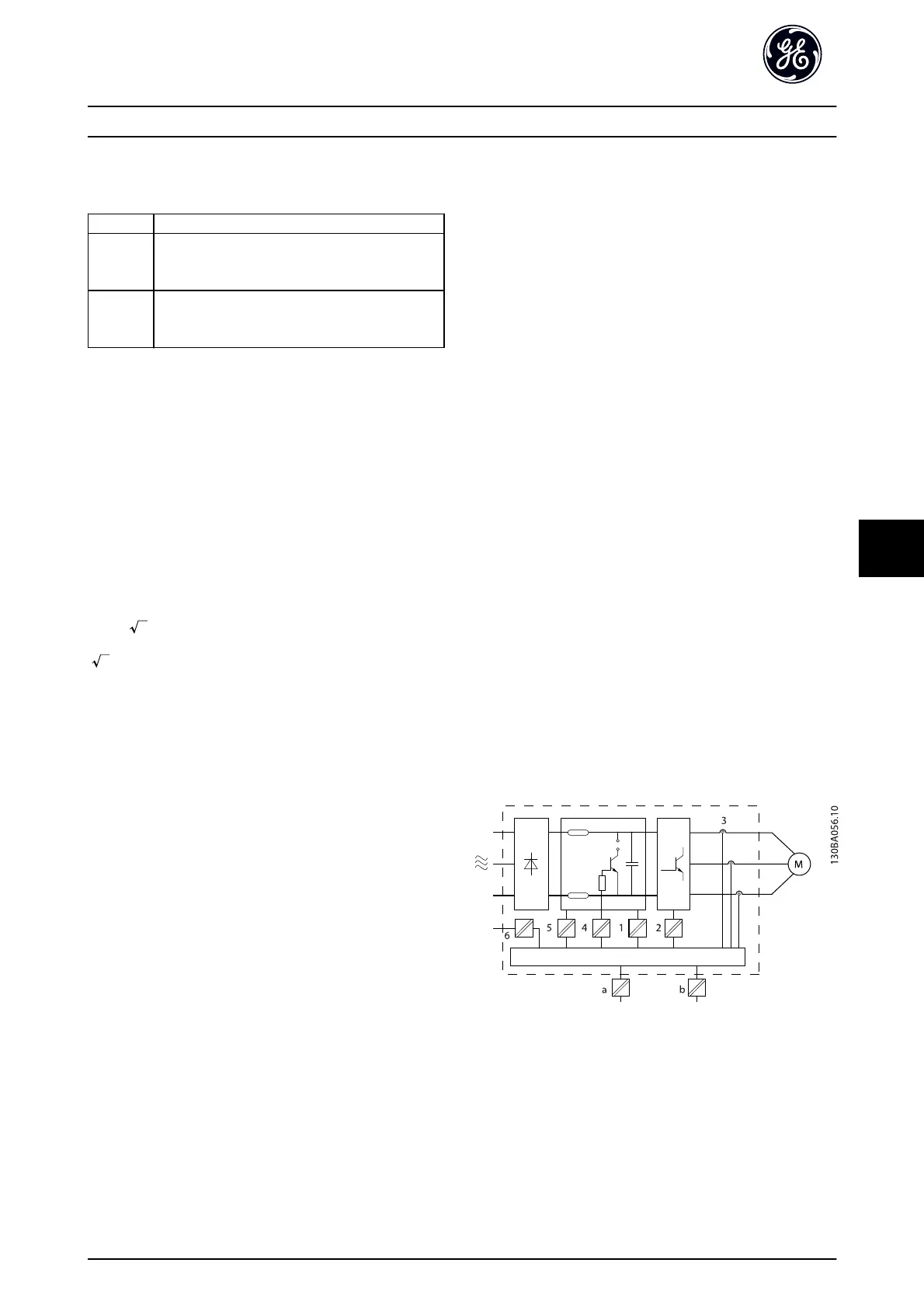

The PELV galvanic isolation can be shown in six locations

(see Illustration 7.3):

In order to maintain PELV all connections made to the

control terminals must be PELV, e.g. thermistor must be

reinforced/double insulated.

1. Power supply (SMPS) incl. signal isolation of U

DC

,

indicating the intermediate current voltage.

2. Gate drive that runs the IGBTs (trigger

transformers/opto-couplers).

3. Current transducers.

4. Opto-coupler, brake module.

5. Internal inrush, RFI, and temperature

measurement circuits.

6. Custom relays.

Illustration 7.3 Galvanic Isolation

The functional galvanic isolation (a and b on drawing) is

for the 24 V back-up option and for the RS 485 standard

bus interface.

Installation Consideration

AF-600 FP

TM

Design and Installation Guide

DET-768b 61

7

Loading...

Loading...