Operating Instructions Installation InstructionsTroubleshooting Tips

Consumer Support

Safety Instructions

8

Electric Dryer

EXHAUST INFORMATION

THIS DRYER COMES READY FOR REAR

EXHAUSTING. IF SPACE IS LIMITED, USE THE

INSTRUCTIONS IN SECTION 9 TO EXHAUST

DIRECTLY FROM THE SIDES OR BOTTOM OF

THE CABINET.

EXHAUST CONNECTION

STANDARD REAR EXHAUST

9HQWHGDWÀRRUOHYHO

3 4

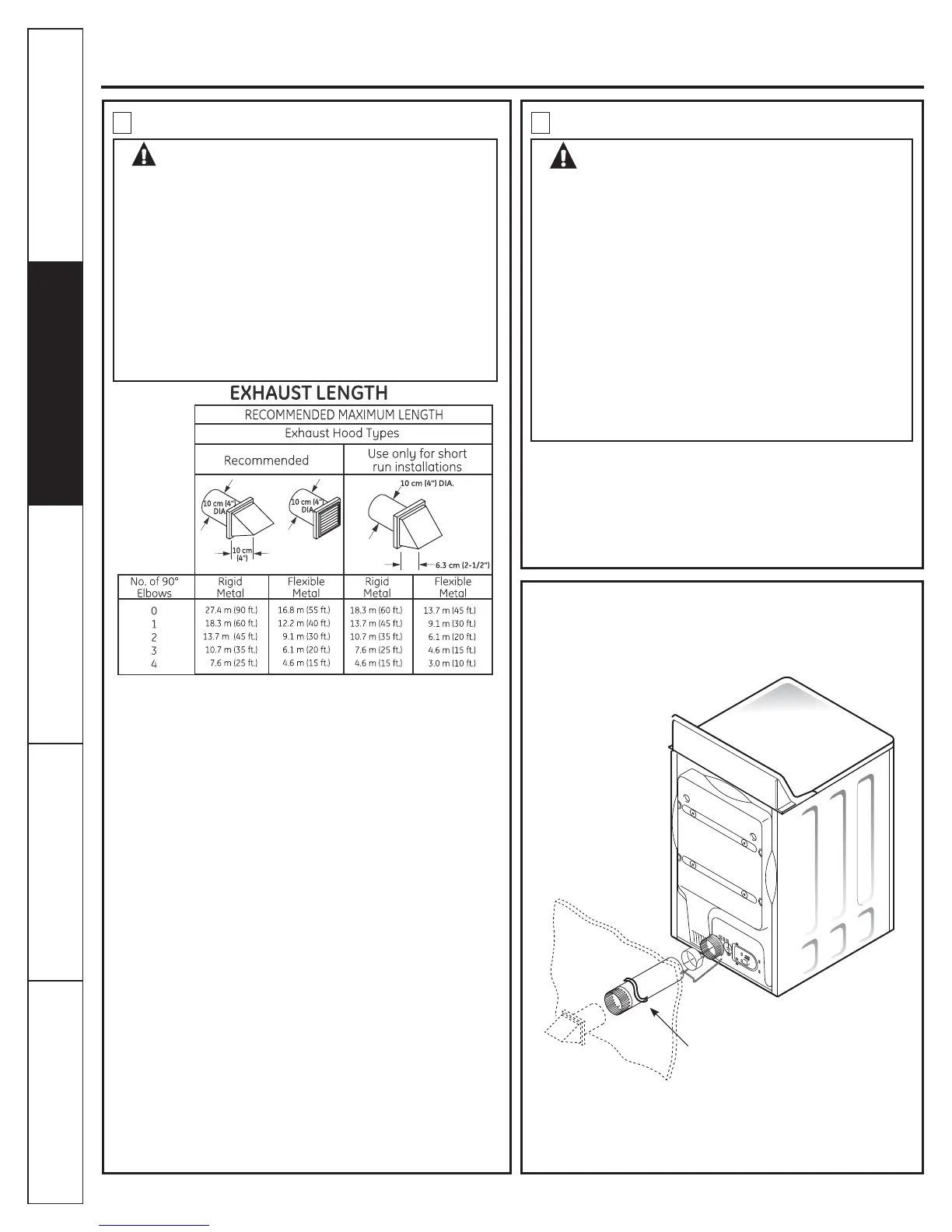

:$51,1*86(21/<0(7$/FPµ

DUCT. DO NOT USE DUCT LONGER THAN

SPECIFIED IN THE EXHAUST LENGTH TABLE.

WARNING - TO REDUCE THE RISK

OF FIRE OR PERSONAL INJURY:

Using exhaust longer than speci¿ed length will

Increase the drying times and the energy cost.

Reduce the dryer life.

Accumulate lint, creating a potential ¿re ha]ard.

The correct exhaust installation is YOUR RESPONSIBILITY.

Problems due to incorrect installation are not covered by

the warranty.

The 0AXI0U0 ALLOWABLE length of the exhaust system

depends upon the type of duct, numEer of turns, the type of

exhaust hood wall cap, and all conditions noted Eelow. Both

rigid and ÀexiEle metal duct are shown in the taEle Eelow.

This dryer must Ee exhausted to the outdoors.

Use only metal duct.

Do not terminate exhaust in a chimney, any gas

vent, under an enclosed Àoor crawl space, or into

an attic. The accumulated lint could create a ¿re

ha]ard.

Provide an access for inspection and cleaning of

the exhaust system, especially at turns. Inspect and

clean at least once a year.

Never terminate the exhaust into a common duct

with a kitchen exhaust. A comEination of lint and

grease could create a ¿re ha]ard.

Do not oEstruct incoming or exhausted air.

EXHAUST SYSTEM CHECKLIST

HOOD OR WALLCAP

Terminate in a manner to prevent Eack drafts or entry of Eirds or other

wildlife.

Termination should present minimal resistance to the exhaust air Àow

and should reTuire little or no maintenance to prevent clogging.

Never install a screen in or over the exhaust duct. This could cause lint

Euild up, thus creating a ¿re ha]ard.

Wall caps must Ee installed at least 3 cm 12 in. aEove ground level or

any other oEstruction with the opening pointed down.

If roof vents or louvered plenums are used, they must Ee eTuivalent to

a 1 cm 4 in. dampened wall cap in regard to resistance to air Àow,

prevention of Eack drafts, and maintenance reTuired to prevent clogging.

SEPARATION OF TURNS

For Eest performance, separate all turns Ey at least 1.2 m 4 ft. of straight

duct, including distance Eetween last turn and exhaust hood.

TURNS OTHER THAN 90º

One turn of 45 or less may Ee ignored.

Two 45 turns should Ee treated as one 9 turn.

Each turn over 45 should Ee treated as one 9 turn.

SEALING OF JOINTS

All Moints should Ee tight to avoid leaks. The male end of each section of

duct must point away from the dryer.

Do not assemEle the ductwork with fasteners that extend into the duct.

They will serve as a collection point for lint.

Duct Moints should Ee made air and moisture-tight Ey wrapping the

overlapped Moints with duct tape.

Hori]ontal runs should slope down toward the outdoors 1.2cm 1/2 in. /ft.

INSULATION

Duct work that runs through an unheated area or is near air conditioning

should Ee insulated to reduce condensation and lint Euild-up.

If using ÀexiEle metal duct, please refer to page 1.

NOTE WE STRONGLY RECO00END SOLID 0ETAL EXHAUST

DUCTING. HOWEVER, IF FLEXIBLE DUCTING IS USED IT MUST BE

0ETAL NOT PLASTIC.

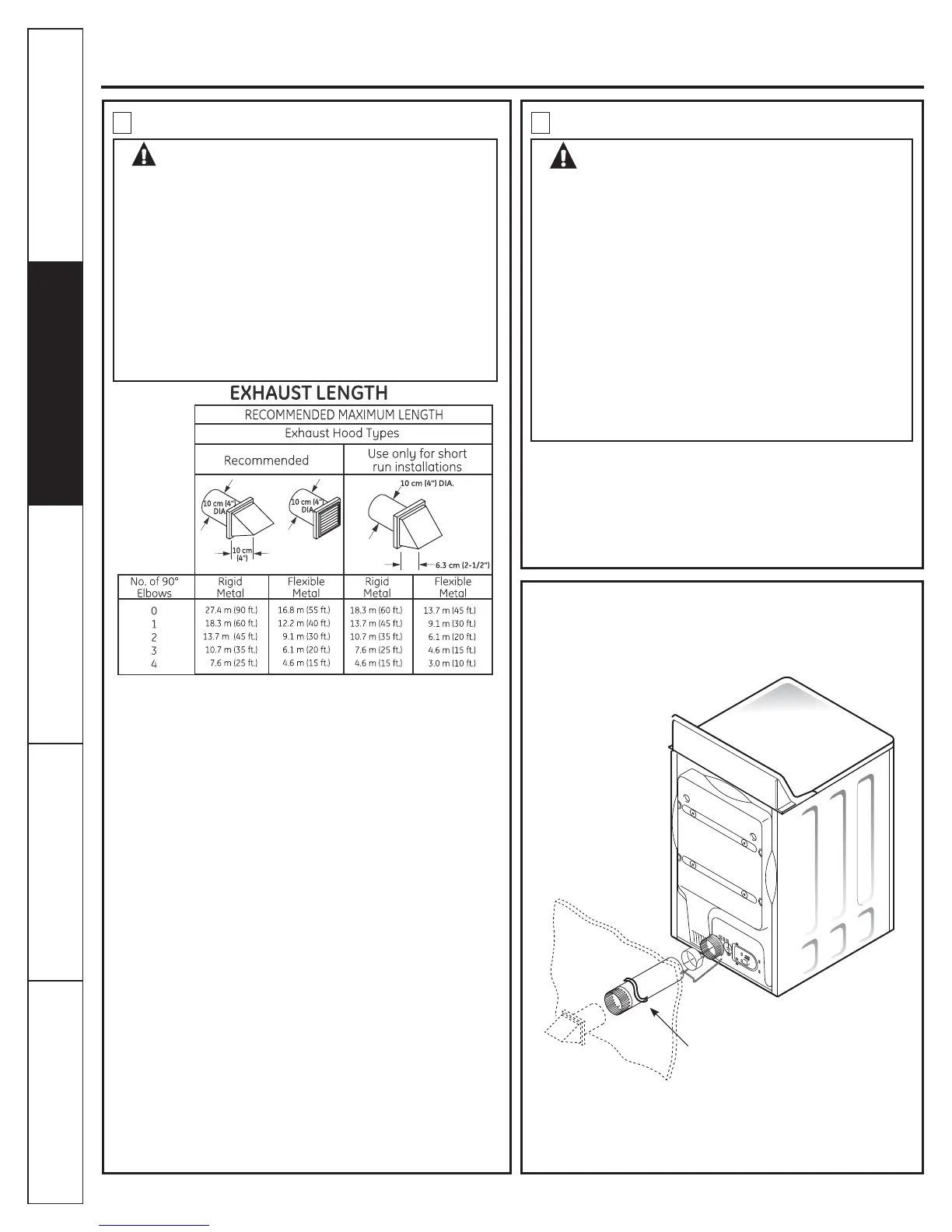

CUT THE 0ETAL EXHAUST DUCT

NOT SUPPLIED TO THE PROPER

LENGTH.

For straight

line installation,

connect the dryer

exhaust to the

external exhaust

hood using duct

tape or clamp.

Loading...

Loading...