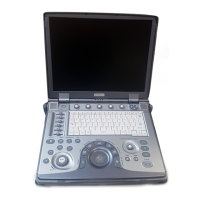

What to do if I want to setup a static IP address on my GE LOGIQ e R4?

- MmichaelgrantAug 3, 2025

To set up a static IP address, uncheck the 'Enable DHCP' option and then enter the static address in the 'IP-Address' box, as well as the appropriate Subnet Mask and Default Gateway.