– 11 –

Surface Burner Adjustments

Standard adjustments to the air shutter and gas

metering orifices are not possible on sealed

burners.

If burner flames appear to be abnormal, check the

following:

• Check gas pressure available to the burners.

The required operating pressure is 5" W.C.P.

Natural Gas or 10" W.C.P. L.P. (Propane) Gas.

• Check for drafts entering the burner box from

behind the cooktop.

• Check for blockage or partial blockage of the

orifice. Inspect the orifice to be sure it has

been drilled on center and is free of debris or

burrs.

• Check the burner alignment per

Burner

Alignment.

• If the cause of the problem cannot be found,

installing an orifice with smaller diameter

openings may solve the problem. In high

altitude (above 6000 ft.) installation, the

orifices will usually have to be downsized.

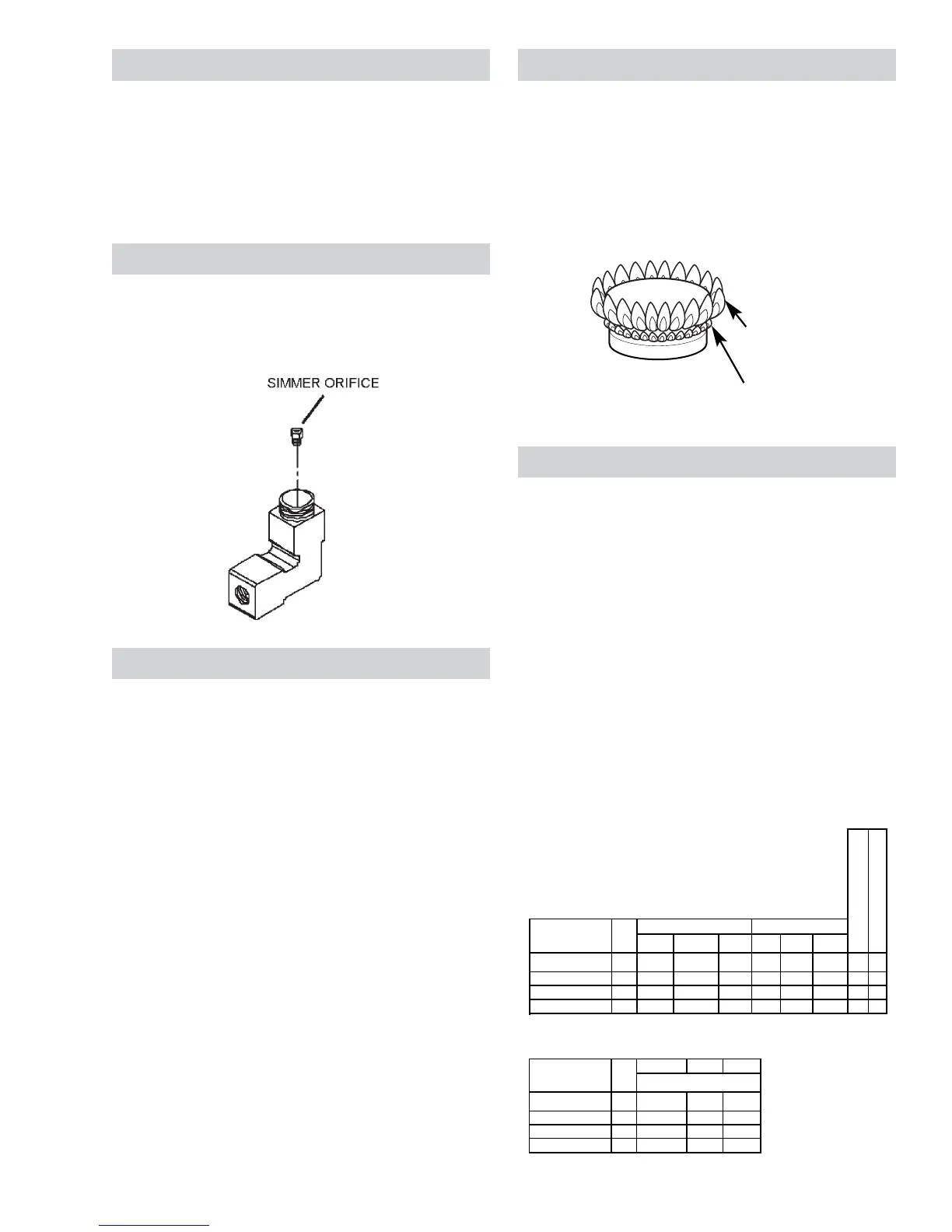

Flame Characteristics

Burner flames should be blue and stable with no

yellow tips. (Yellow tipping may be normal for LP

gas.) The flame should not have excessive noise

or lifting of the flame from the burner. If any of

these conditions exist, check the burner ports for

blockage.

Orifice Conversion Kits

Burner orifice conversion kits are available for:

• Converting burner orifices from LP to Natural

Gas and from Natural Gas to LP

• Installation at high altitudes

Natural/LP Conversion Kit - Order part number

WB49X10132

LP/Natural Conversion Kit - Order part number

WB49X10133

High Altitude Conversion Kit – Order part number

WB49X10130

ORIFICE/JET SIZES

ORIFICE (mm) RATE (BTU/HR)

BURNER GAS MAIN SIMMER Valve HI LO SIM

D BURNER NG 1.85 0.57 mm 0.57 17k 2700 1300 185 P

D BURNER LP 1.18 0.34 mm 0.34 15k 2500 1200 118 E

GRILL/GRIDDLE NG 1.93 ––––– 0.94 18k 6000 –––– 48 –––

GRILL/GRIDDLE LP 1.32 ––––– 0.47 18k 6000 –––– 55 –––

MAIN ORIFICE CODE

SIMMER ORIFICE CODE

ORIFICE/JET SIZES

Sea Level 3000 ft. 6000 ft.

BURNER GAS MAIN Orifice (mm)

D BURNER NG 1.85 1.78 1.61

D BURNER LP 1.18 1.09 1.07

GRILL/GRIDDLE NG 1.93 1.85 1.70

GRILL/GRIDDLE LP 1.32 1.32 1.18

HIGH ALTITUDE CONVERSION

Recommended Orifice Size for High Altitude Installation

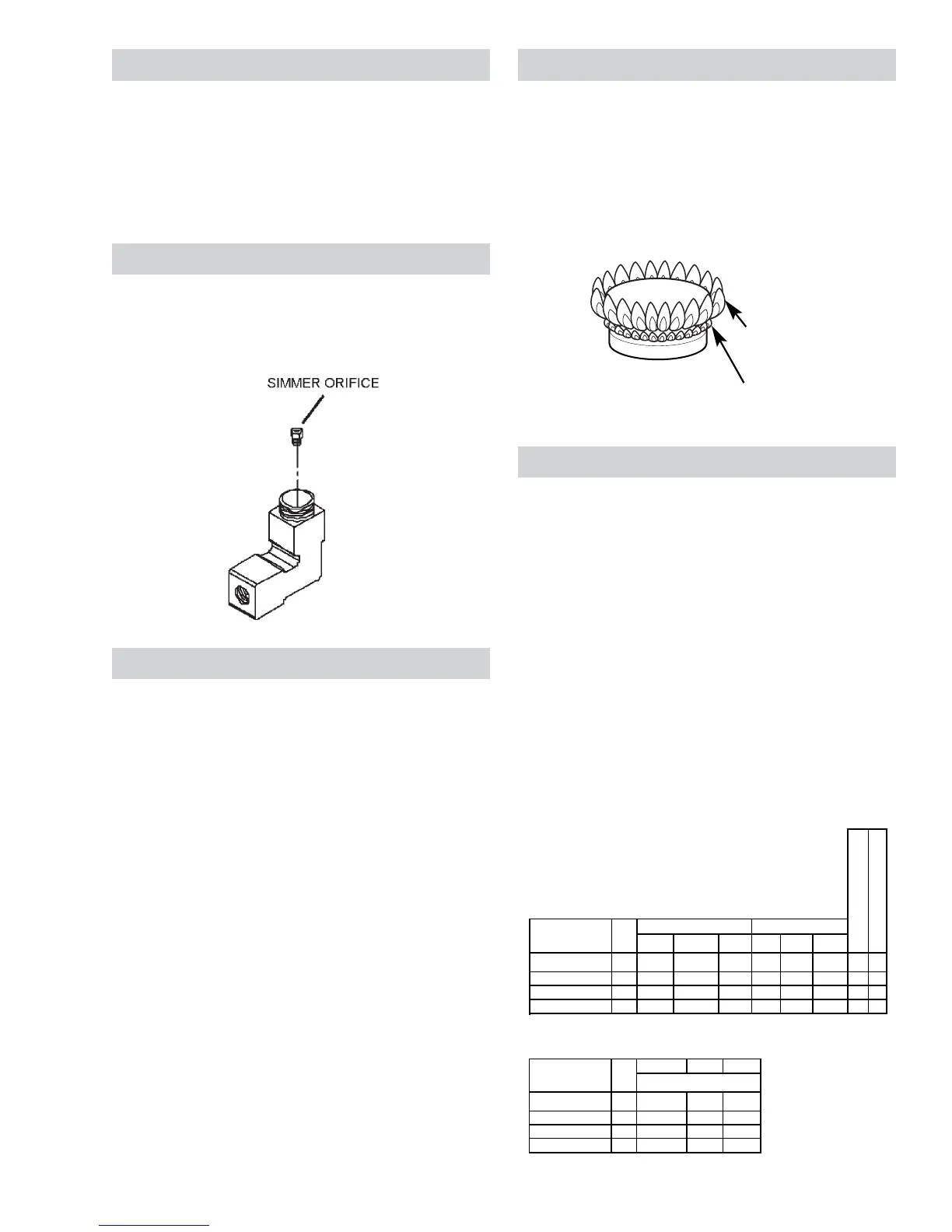

Simmer Orifice Burner Replacement

The simmer burner orifice requires a 4mm socket

to remove it. If necessary a 4mm socket is

available under part # WX05x10006.

Burner Valve

The burner valves are attached to the manifold by

two screws and contains an orifice which sets

the flow rate for the simmer flame. This valve

does not have a low flame adjustment, it is

controlled by the orifice size.

Loading...

Loading...