Operation

33

SecoVac 3.3kV-27kV Embedded Pole Vacuum Circuit Breaker

Working Principle

Working Principle of Operating

Mechanism

The vacuum gas pressure inside vacuum interrupter is less than

1.33×10

-3

Pa. Under normal circuit conditions the interrupter is

closed. Arcing is established within the interrupter by withdrawing

the moving contact from stationary contact. This arc burns in

the metal vapor evaporated from local hot spots on the contact

surfaces. The metal vapor continually leaves the inter-contact

region and recondenses on the contact surfaces and surrounding

metal vapor condensation shield. The latter is usually isolated

from both contacts and serves to protect the glass or ceramic

envelope from vapor deposition. At current zero, vapor production

ceases and the original vacuum condition is rapidly approached.

The dielectric strength of the interrupter also increases, and the

circuit is interrupted. Within the contacts in the open position, the

circuit voltage is withstood internally by the inter-contact gap

and externally by the insulating envelope.

The energy that is necessary for closing the circuit breaker is

provided by the closing spring. The energy storage can be done

by the motor or by the manual charging handle.

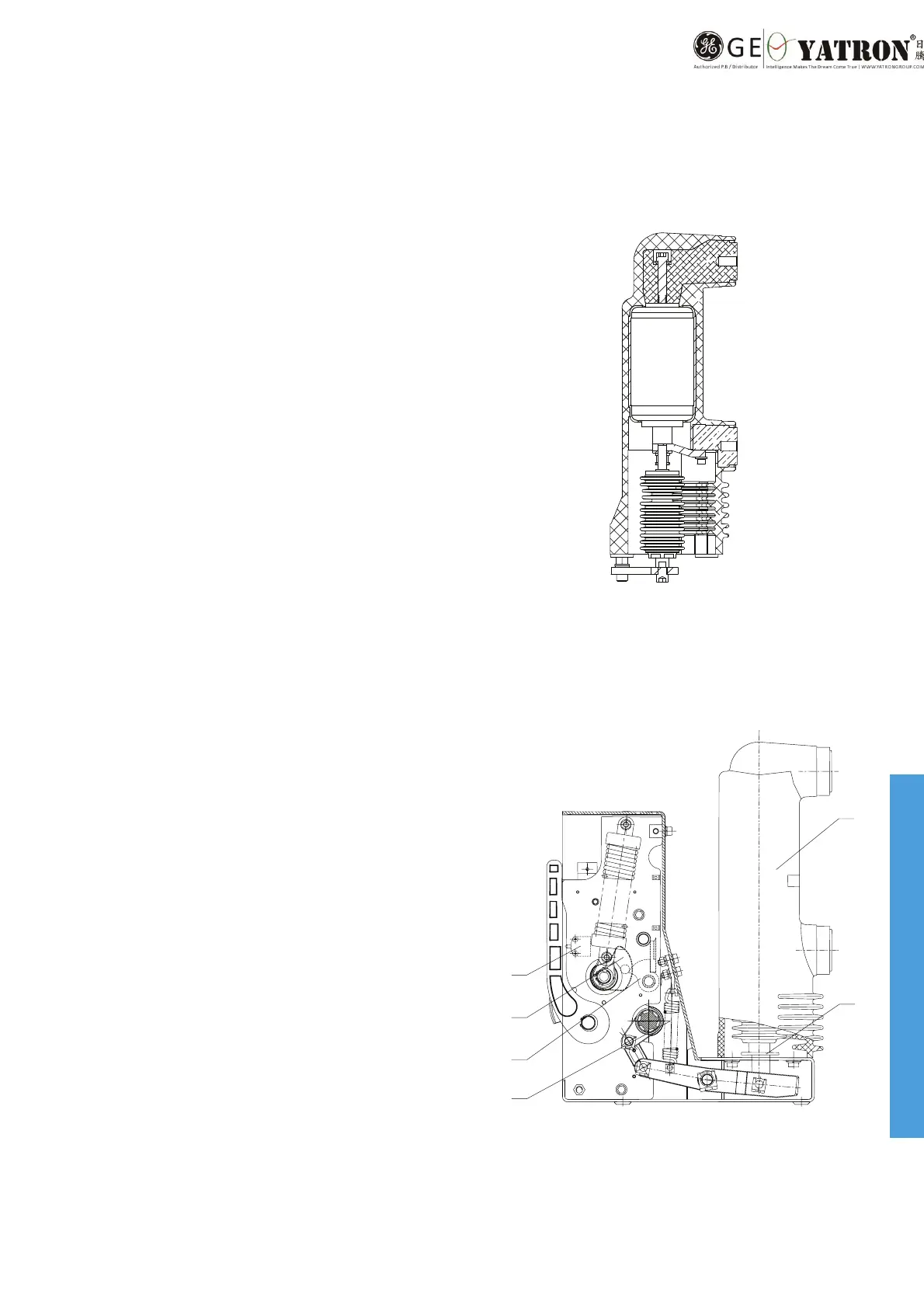

Motor spring charging

The energy charging mechanism consists of energy storing

motor, gear wheel, cam, holder and closing spring. When the

energy-storing motor (11) is charged, the pinion of output shaft

(12) that is connected to motor will rotateand drive the gear

on the shaft move, which then drive the shaft to rotate, so that

draws out the closing spring (17) for storing energy. When the

block on the gear wheel is pushed away, the clutch is separated

mechanism in charged position, thus completing the charging

operation succeeds.

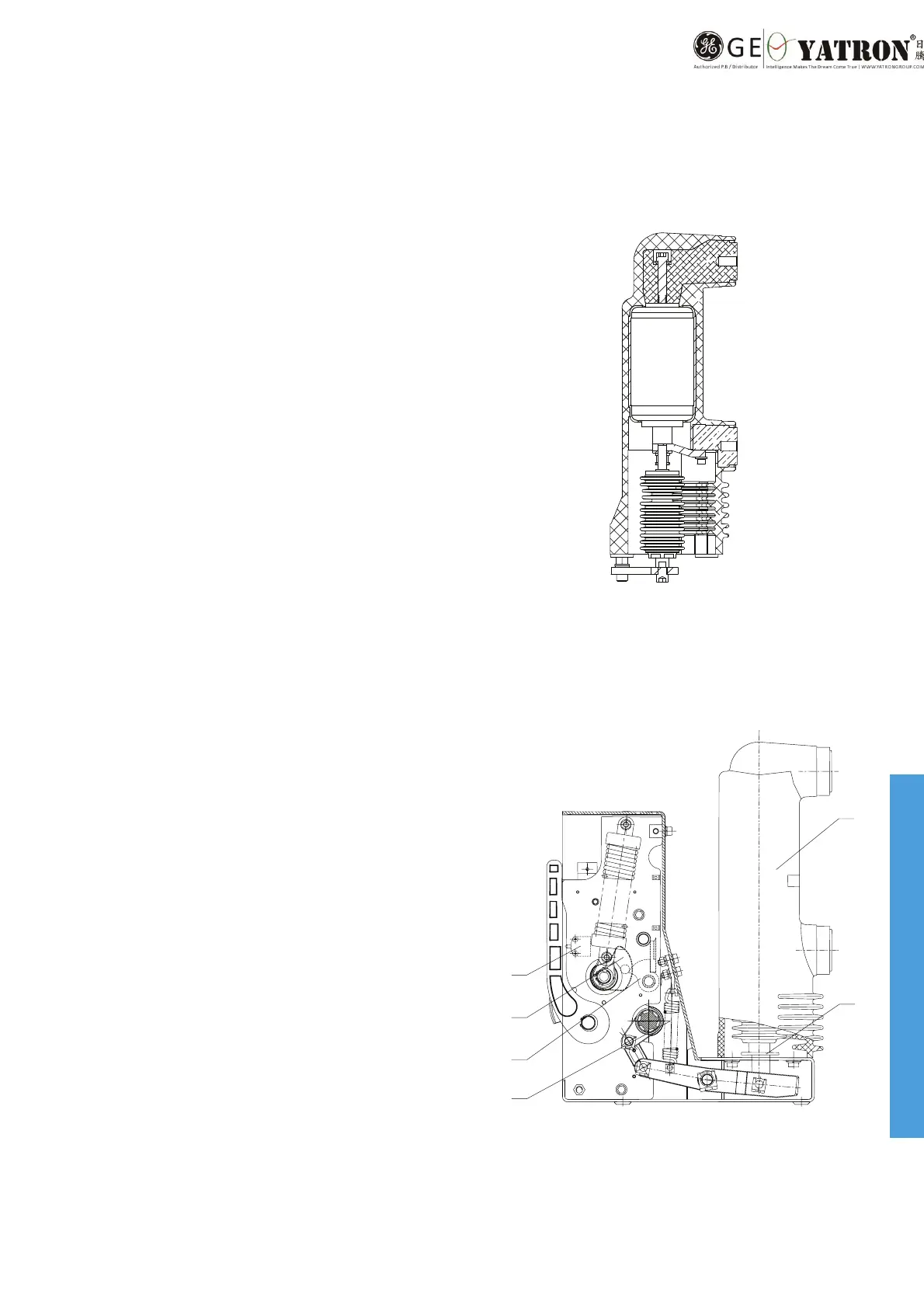

Vacuum interrupter

Motor spring charging

1

2

3

4

5

6

Figure 3.

1 Embedded pole

2 Insulating rod

3 Opening spring

4 Holder

Cam

6 Position switch

Loading...

Loading...