Maintenance

Maintenance plan

GE Information08- 2016 L51- 004EN/07

3/8

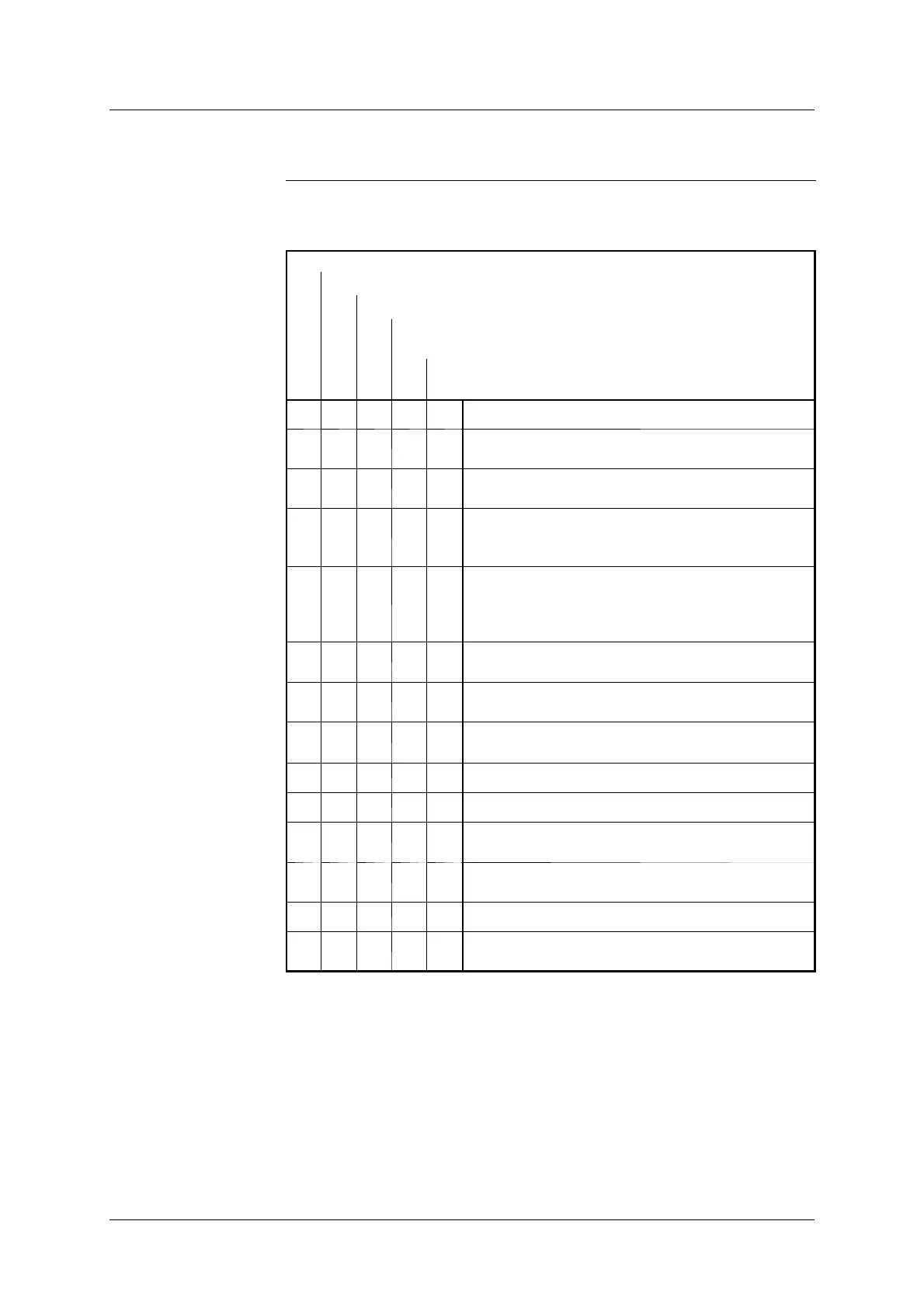

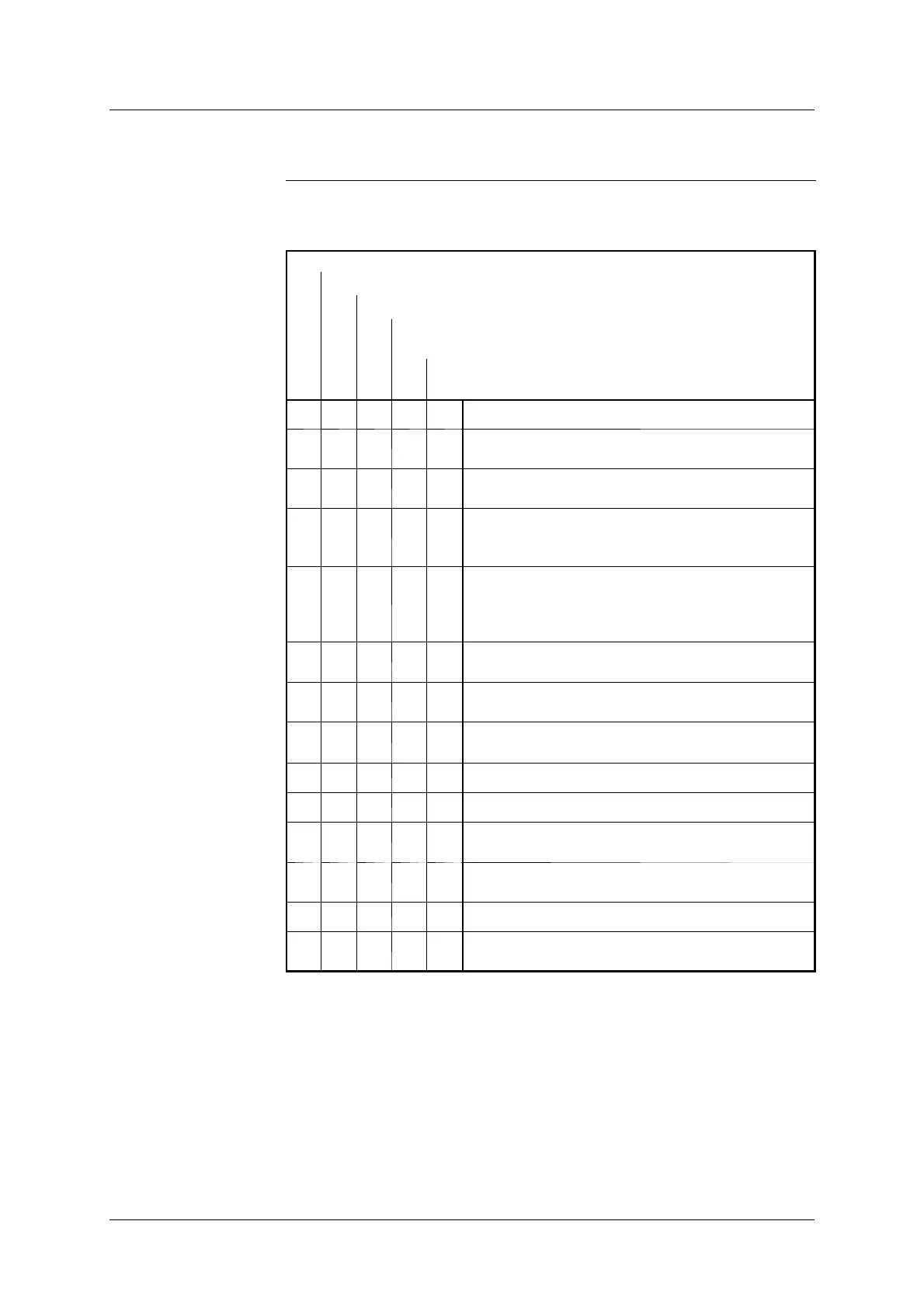

Maintenance operations

Guide

The table below is a guide of the operations to be carried out at each

maintenance stage:

(M1) MAINTENANCE VISITS (1 or 2 times a year)

(M2) INSPECTION (every 5 years)

(M4) OVERHAUL (OPERATING TIME: 20 years)

(M4) OVERHAUL (MECHANICAL OPERATIONS: 3 000

cycles)

(M4) OVERHAUL (ELECTRICAL WEAR: see

“Electrical wear limits”)

■ ■ ■ ■ ■

Operation counter reading.

■ ■ ■

Overall inspection: appearance (corrosion,

paintwork, signs of overheating).

■ ■ ■ ■ ■

Check operation of permanent heating. Check

condition of air vents.

■ ■ ■

If the circuit- breaker is fitted with an SF

6

dial

densimeter or a pressure gauge, check SF

6

pressure (or SF

6

+CF

4

gas mixture).

■

It is advisable to perform at least 2 CO duty cycles

per year , when apparatus are scarcely used,in

order to check that circuit- breaker and associated

control circuits are working properly.

■ ■

Check SF

6

densimeter thresholds. Then adjust

pressure to its rated value.

■ ■ ■

Check tightening of parts not subjected to pressure

(frame - deck - cubicle).

■ ■ ■ ■

Check tightening of low voltage terminals (* 6

months after commissioning).

■ ■ ■

Check relay operation.

■

Change door seal, side panels seal and roof seal.

■ ■ ■ ■

Measure operating times for poles and auxiliary

contacts.

■ ■ ■ ■

Carry out operations at recommended duties and

rated voltage.

■ ■

Change (or recondition) interrupting chambers.

■

Check that the damper piston for the opening of the

control presents no oil leak.

Continued on next page.

Loading...

Loading...