Maintenance

Maintenance plan

GE Information08- 2016 L51- 004EN/07

4/8

Maintenance operations, continued

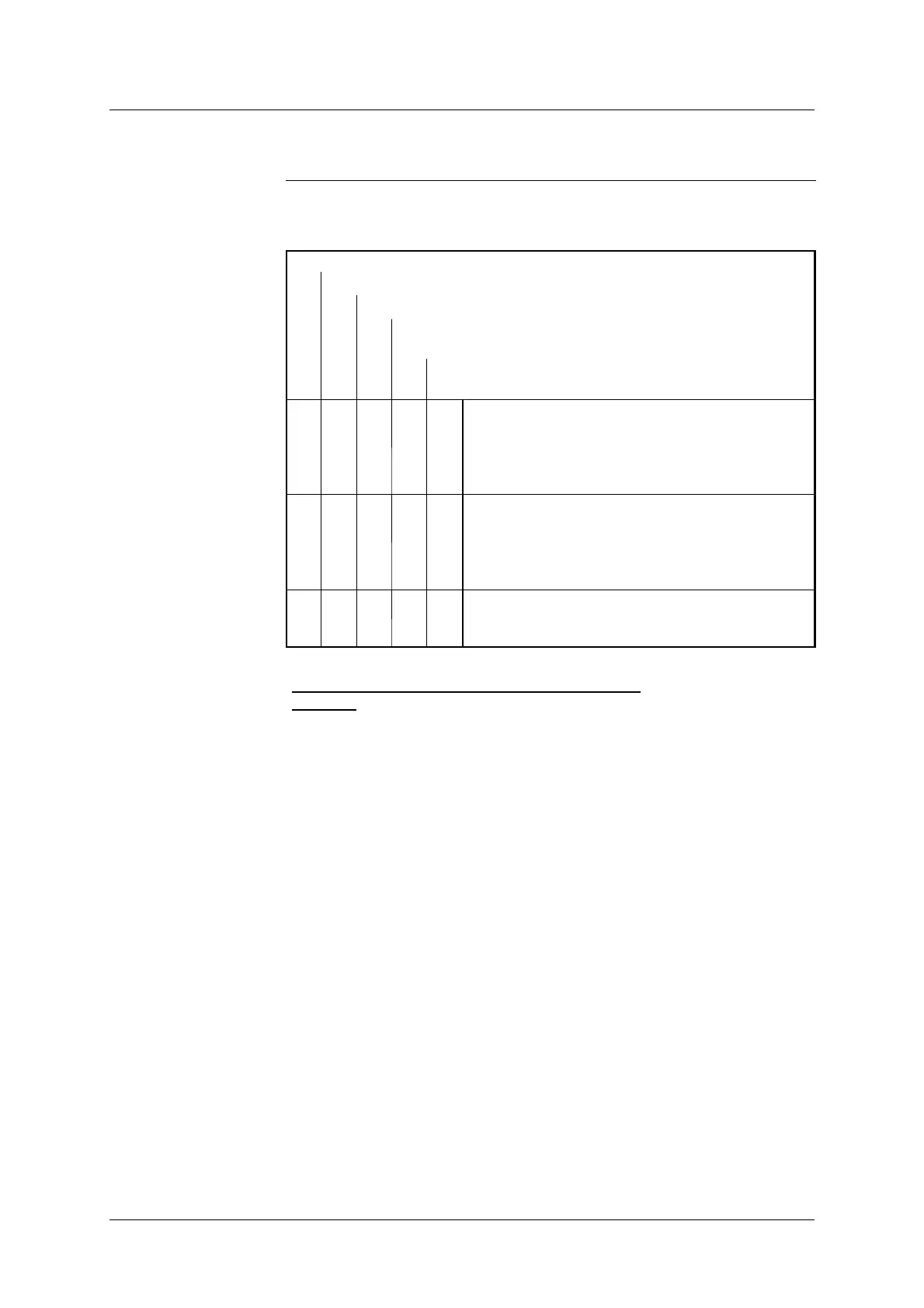

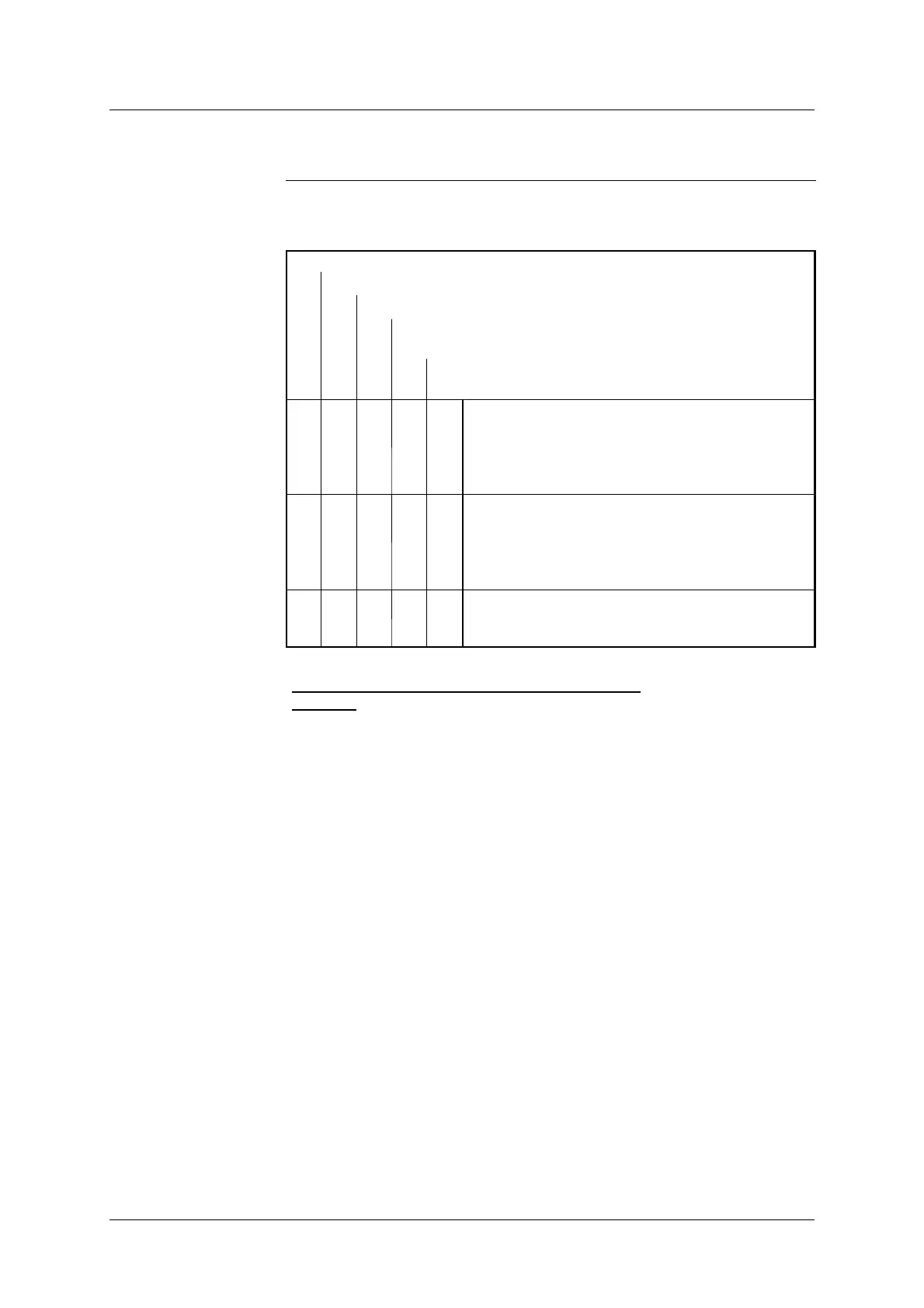

Guide

The table below is a guide of the operations to be carried out at each

maintenance stage:

(M1)- MAINTENANCE VISITS (1 or 2 times a year)

(M2)- INSPECTION (every 5 years)

(M4)- OVERHAUL (OPERATING TIME: 20 years)

(M4)- OVERHAUL (MECHANICAL OPERATIONS: 3 000

cycles)

(M4)- OVERHAUL (ELECTRICAL WEAR: see

“Electrical wear limits”)

☆

Monitoring devices and/or Point on Wave relays:

Check for the presence of alarms on the front

panel. Carry out a download from the equipment

and save the archive & config. files to a local hard

drive for analysis.

☆ ☆ ☆ ☆

Monitoring devices and/or Point on Wave relays:

Check for the presence of alarms on the front

panel. Carry out a download from the equipment

and save the archive & config. files to a local hard

drive for analysis.

☆ ☆ ☆ ☆

Point on W ave relays: update the time taken for

breaking chamber and auxiliary contact operations

(time shift), then reset the adaptive control.

☆ Compulsory for monitoring device and/or Point on Wave relays

Conditional maintenance for Point on Wave relays

:

Caution: When using with a shunt, if the number of operations per day is

greater than or equal to 1, carry out the operation every two years:

Update the time taken for breaking chamber and auxiliary contact

operations (time shift), then reset the adaptive control.

Loading...

Loading...