Hint!

If you fail to adhere to the limiting val-

ues stated in VDI 3803, the manufac-

turer cannot provide any warranty for

water carrying parts within its supplied

components.

Clarification as to whether or not it is

possible to adhere to these limiting

values with the respective water condi-

tions should be agreed on with a spe-

cialist company during the planning

and design phase.

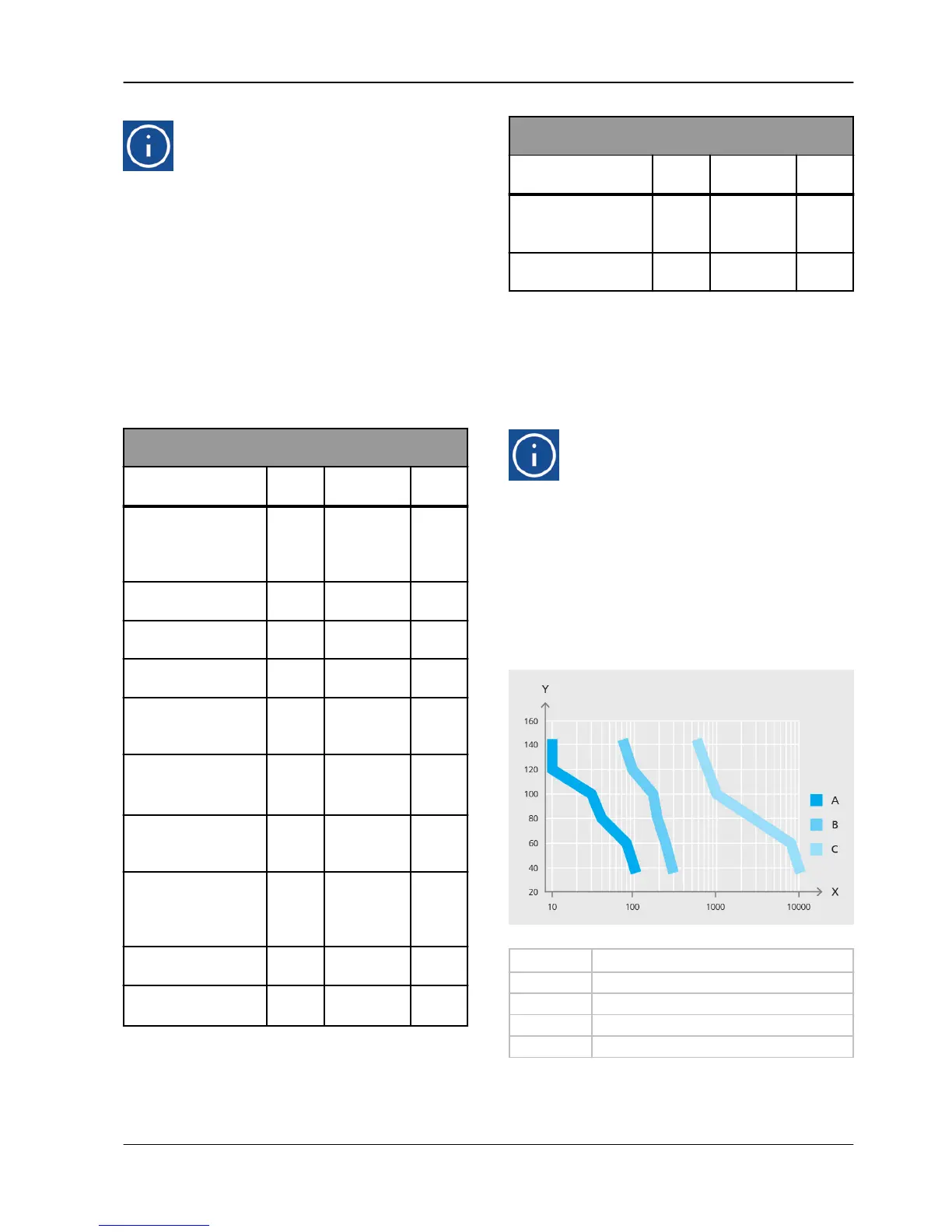

The limiting values as per VDI 3803, as required for

the use of carbon steel components in non corrosive

water systems, are listed below.

Water quality requirements, parameters

Criterion

Value Unit

Appearance

clear, with-

out sedi-

ment

Colour

colourless

Odour

none

pH level at 20 °C

7.5 - 9.0

Electrical conductiv-

ity

LF < 220 mS/m

Soil alkali

Ca

2+

,

Mg

2+

< 0.5 mol/m³

General hardness,

for stabilization

GH < 20 °d

Carbonate hard-

ness without hard-

ness stabilizer

KH < 4 °d

Chloride Cl < 150 g/m³

Sulphur

SO

4

< 325 g/m³

Water quality requirements, parameters

Criterion

Value Unit

Active biological

components

KBE < 10,000 per ml

Thickness factor EZ 2 - 4

The use of carbon steel and cast iron is required in

the most of applications water conditioning with cor-

rosion inhibitors.

The use of stainless steel requires very special moni-

toring of water in apply to Chloride contents (risk of

stress crack and pitting corrosion).

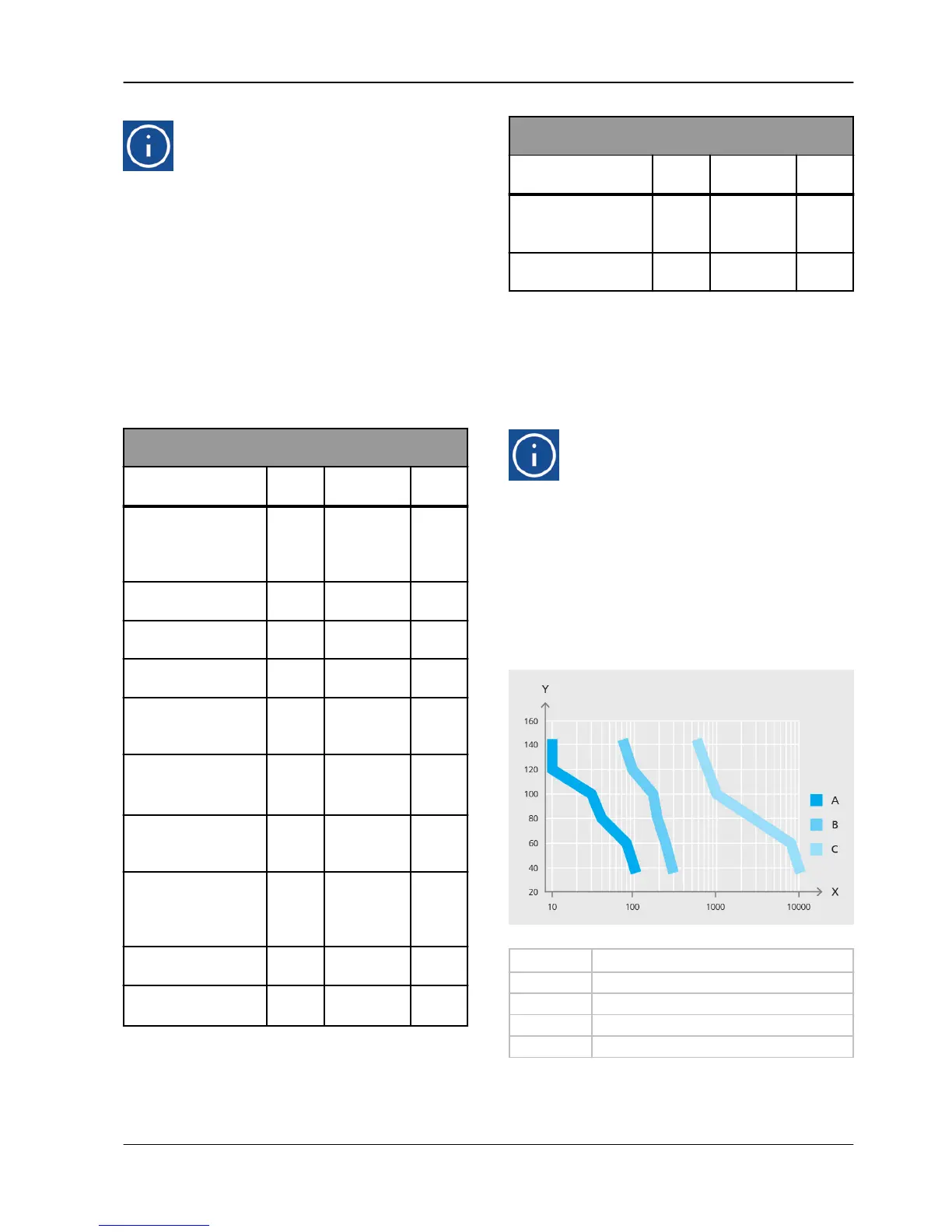

Hint!

Recommend when using plate heat

exchangers in the refrigerant circuit

< 100 ppm Cl while using steel 1.4301

and

maximum 40°C wall temperature in the

plate heat exchanger

< 200 ppm Cl while using steel 1.4401

and

maximum 100 °C wall temperature in

the plate heat exchanger

fig.28: Corrosion resistance in presence of chlorides

X

Chloride ion concentration in ppm Cl

-

Y Wall temperature heat exchanger in °C

A AISI 304

B AISI 316

C SMO 254

Operating Manual | GEA Grasso M-Series

Screw Compressor Packages

Description of Design and Function

GEA Refrigeration Germany GmbH | P_261511_1 | Generated 01.04.2015 51

Loading...

Loading...