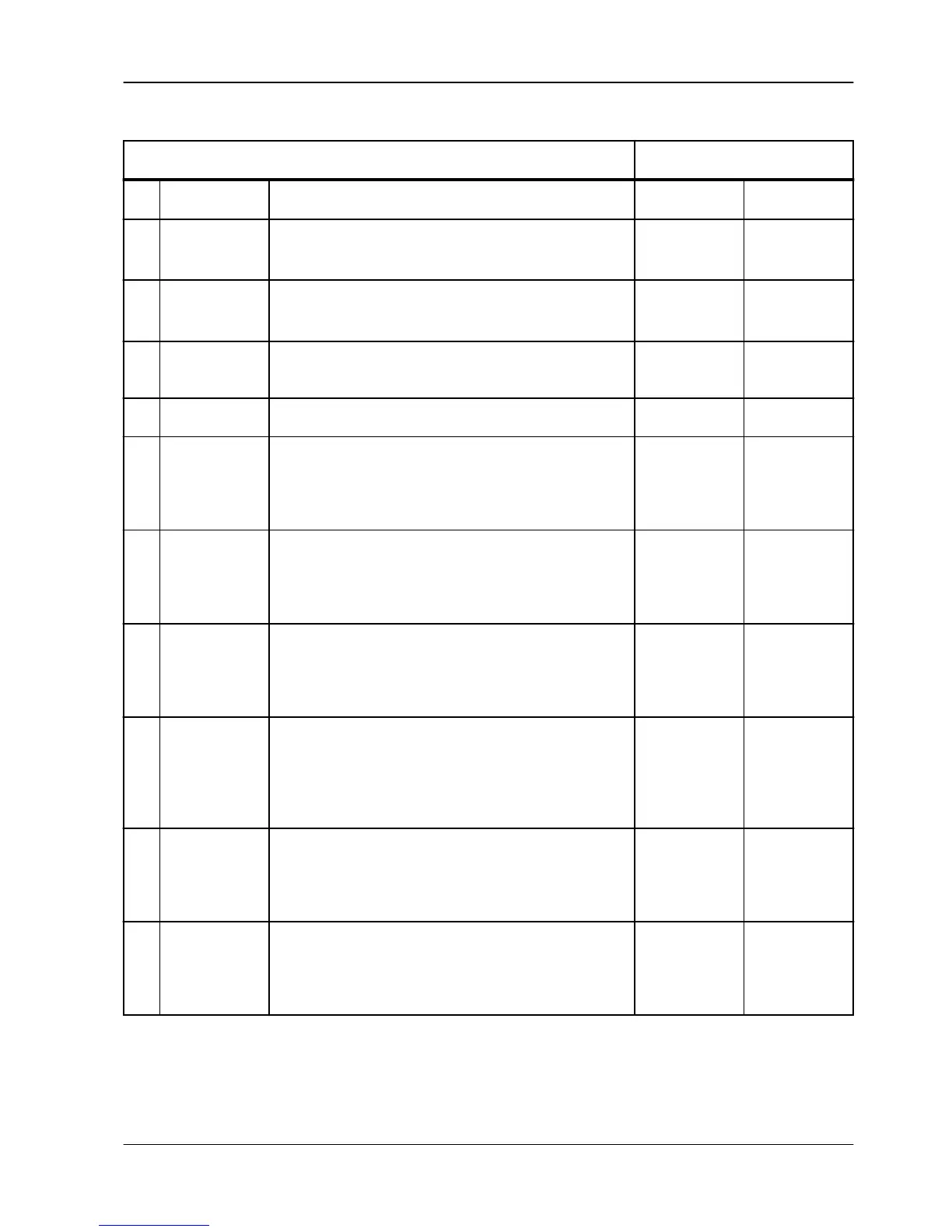

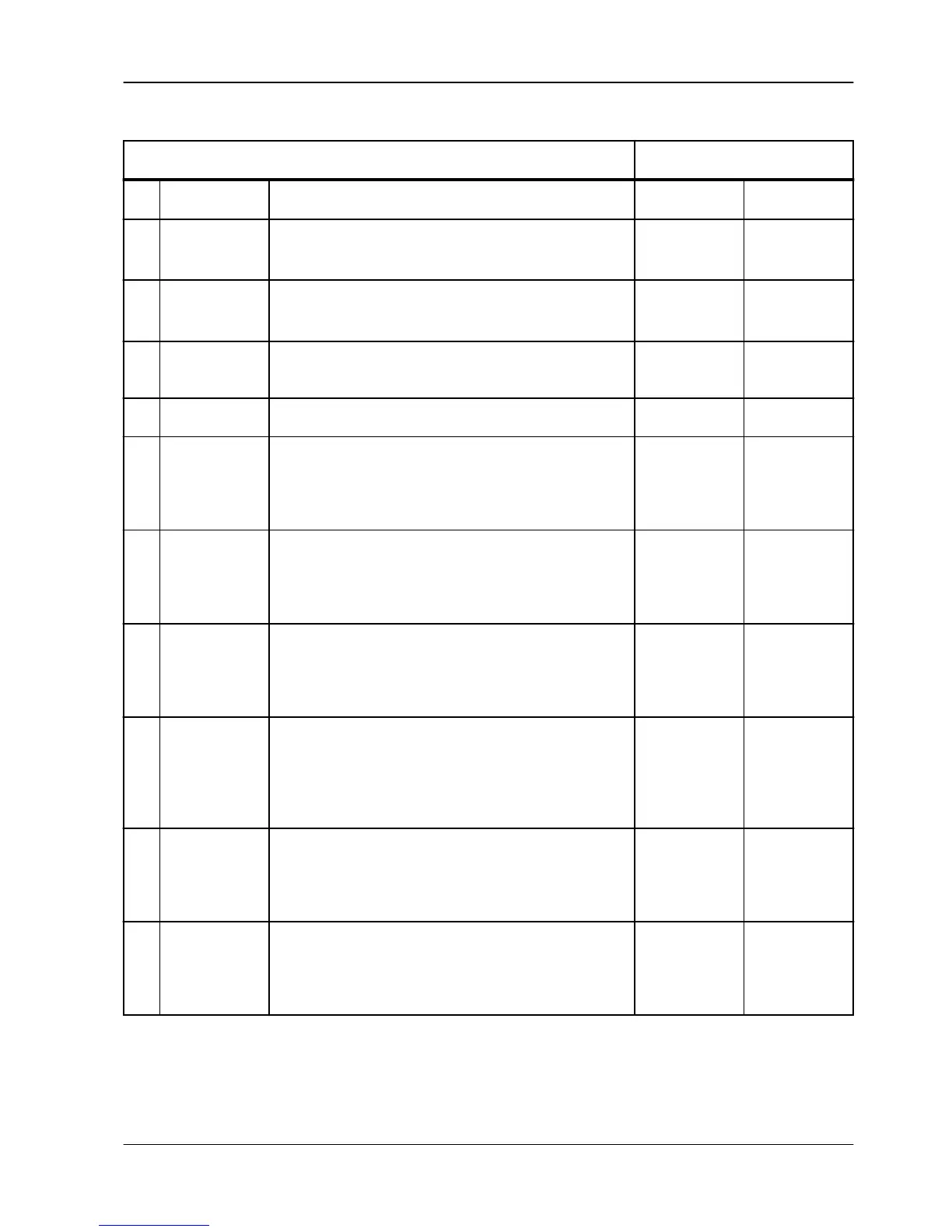

9.3.1 Overview of the operating modes

Modes Signal for …

Name Remark Start/Stop Capacity +/-

0 Service Oil pump by itself

Compressor motor blocked

1 Manual

+ Manual

Manual control via Touch Panel (TP) Manual Manual

2 Manual + Auto Manual Start/Stop via TP and full automatic local

capacity control

Manual Auto

3 Auto + Auto Full automatic start/stop and local capacity control Auto Auto

4 Remote

+ HW (cont)

Start/stop and capacity demand via digital contacts

(hardware) from a remote master controller. The GSC

TP derives from the continuous +/- signals the pulses

for capacity (indirect).

External External

continuous

5 Remote

+ HW (pulse)

Start/stop and capacity demand via digital contacts

(hardware) from a remote master controller. The mas-

ter also generates the +/- signals as pulses for control-

ling the slide capacity directly.

External External

pulses

6 Remote

+ HW (loc.

SW)

Start/Stop from a remote master controller via digital

contacts (hardware). The GSC TP controls the output

depending on a local setpoint (TP) and from this set-

point also automatically switches the product ON/OFF.

External

+ setpoint

deviation

Local

Setpoint

7 Remote

+ HW (ext.

SW)

Start/Stop from a remote master controller via digital

contacts (hardware). The GSC TP controls the output

depending on an external setpoint (analog input) and

from this setpoint also automatically switches the

product ON/OFF.

External

+ setpoint

deviation

Remote

Setpoint

8 Remote

+ Net (cont)

Start/stop and capacity demand via network from a

remote master controller. The GSC TP derives from

the continuous +/- signals the pulses for controlling the

capacity (indirect).

Network Network

continuous

9 Remote

+ Net (pulse)

Start/stop and capacity demand via network from a

remote master controller. The master also generates

the +/- signals as pulses for controlling the capacity

directly.

Network Network

pulses

Operating Manual | GEA Grasso M-Series

Screw Compressor Packages

Use, operation, control

GEA Refrigeration Germany GmbH | P_261511_1 | Generated 01.04.2015 67

Loading...

Loading...