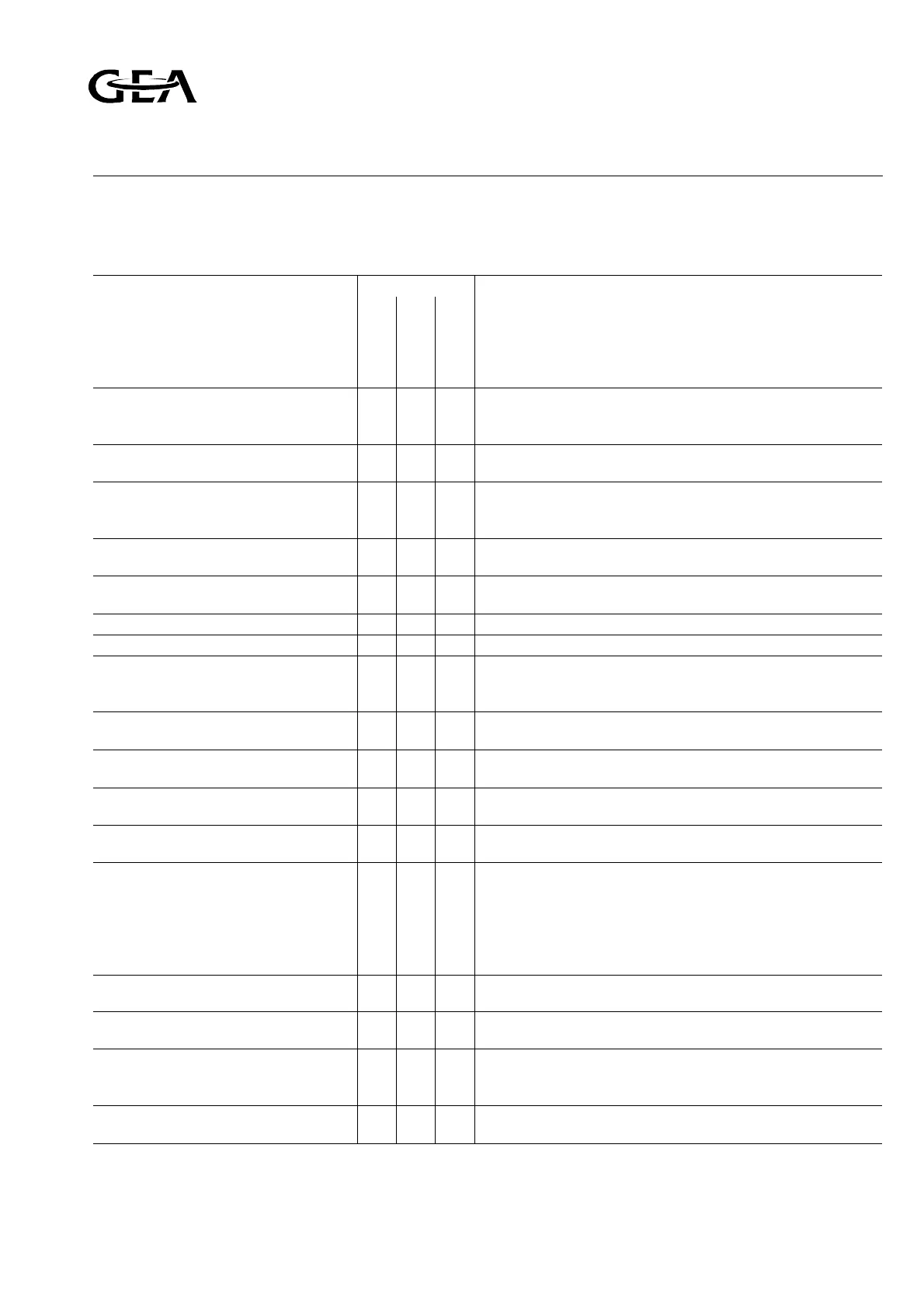

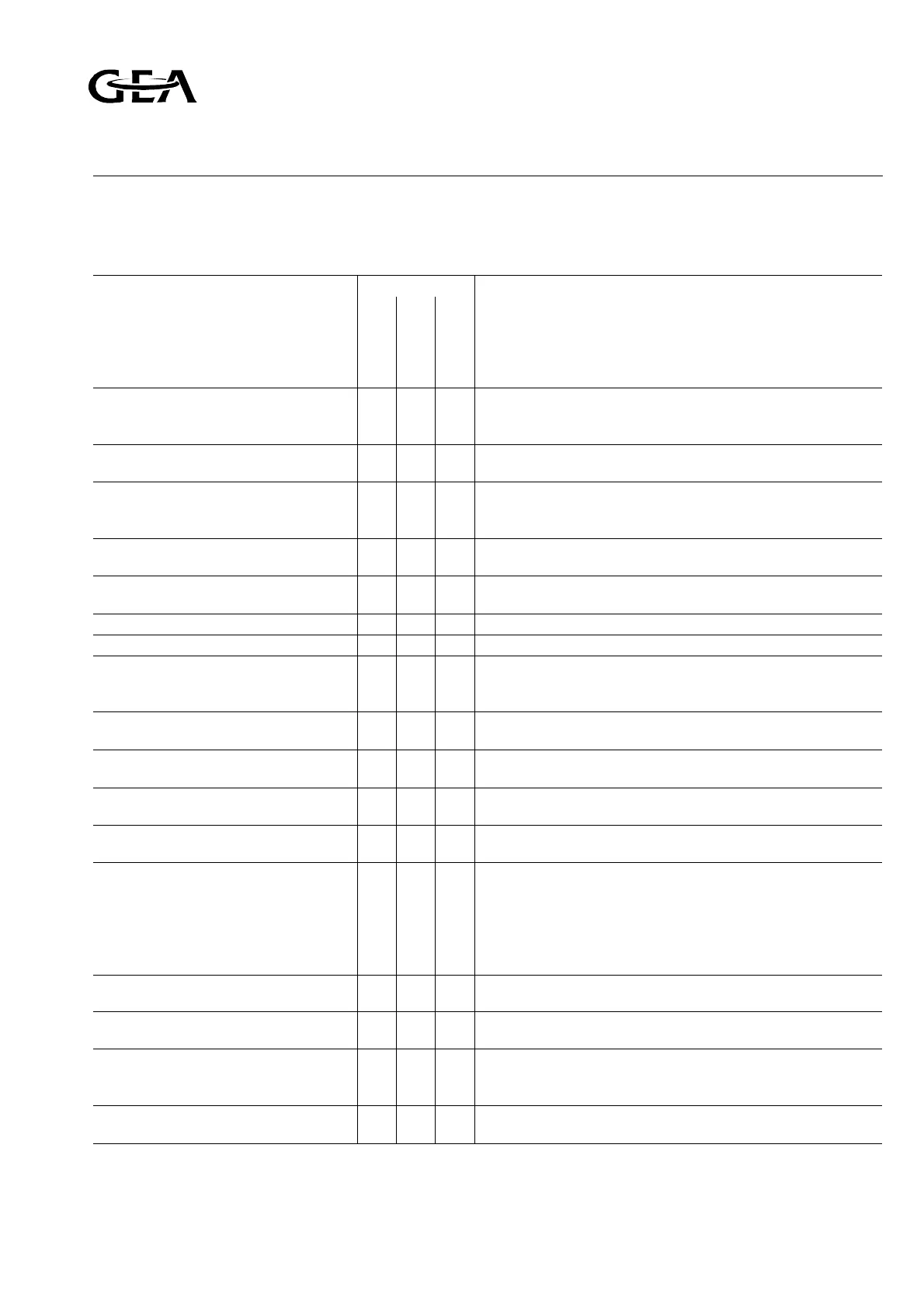

8.1 SURVEY OF PERIODICAL INSPECTIONS ("CHECK LIST")

(Also refer to the explanation overleaf)

FREQUENCY

CHECK POINTS

daily

weekly

monthly

REMARKS

Oil level in crankcase

•

The oil level must be between 1 and 3 quarters

height of the sight glass. For topping up oil, refer to

Chapter 9, Compressor Maintenance.

Colour of the oil

•

The oil should be transparently clear. A disappearing

white colour points to dissolved refrigerant.

Lubricating oil pressure

•

The indication of the oil pressure gauge should be

1.5 bar higher than the value shown by the suction

pressure gauge.

Oil temperature

•

The maximum allowable temperature is 70 °C,

measured on the suction line to the oil suction filter.

Return from oil separator

•

To be checked only when a sight glass is provided in

the oil return line.

Oil leakage

•

Remedy visible oil leakage.

Suction pressure

•

Refer to plant manual.

Discharge pressure

•

Refer to plant manual. For the max. allowable

discharge pressure refer to Chapter 3, Technical data

of compressor.

Suction temperature

•

The suction temperature should indicate at least 5 K

superheat.

Discharge temperature

•

The maximum allowable discharge temperature is

170 °C.

Cooling water temperature (if

water cooling is applied)

•

Water temperature must be higher than condensing

temperature.

Crankcase heating (if provided)

•

During compressor standstill the crankcase bottom

side must remain warmer than the surroundings.

Condition of V-belts

•

Check belts for: 1) wear (fraying, cuts etc.) and

ensure that they do not touch the groove bottom; 2)

Tension. Too low a tension gives rise to excessive

flapping or oscillation in operation. For correct

tension consult the instructions given by the V-belt

supplier.

Adjustment and operation of pressure

safety switches

•

Refer to Chapter 7 and to the plant manual.

Switching frequency of the

compressor

•

The time interval between stopping and starting

should be at least 10 minutes.

Capacity control (if provided)

•

The time lag between the unloading and loading of

one cylinder or cylinder group should generally be at

least 3 minutes.

Number of operating hours

•

Check the number of operating hours in view of any

maintenance operations to be carried out.

Apart from the above check points, the sound produced by the compressor provides a proper standard

for its mechanical condition. If abnormal sounds are audible, their cause should be traced and removed

immediately in order to prevent serious breakdowns at inconvenient times.

Refrigeration Division

Grasso

8. PERIODICAL INSPECTION OF THE OPERATING COMPRESSOR

v002.97.10.en Refrigeration Compressors Series RC9 Page 8.1

Loading...

Loading...