5-3

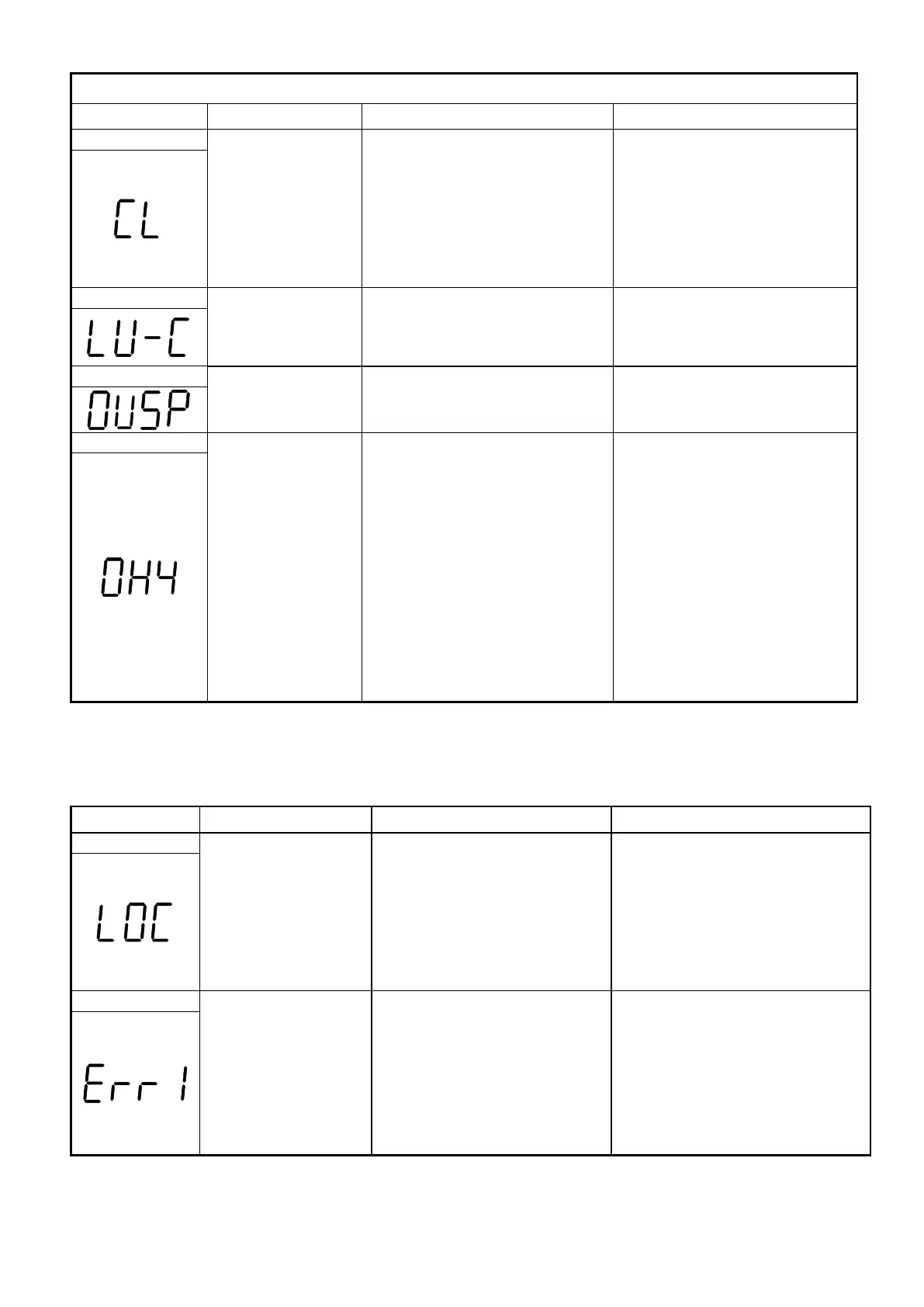

Faults which can be recovered manually but not automatically

current:

Wait 1 minute to

reset. If it occurs

CL or OL2 up to 4

successive times

then wait 5

Inverter over current warning:

inverter current reach the level

of over current protection

Check load condition and

running period time.

Voltage too low

during operation

1.Power voltage too low

2.Power voltage varies widely

(fluctuates)

1.Improve power quality

2.Consider adding a reactor

motor rotation

over speed

The actual rotation speed is

different to the set speed.

1.Check for excessive load

2.Check weather frequency

setting signal is right or not

motor over heat

error

1.If temperature detected

increases above the set limit in

parameter 08-13 and for the

delay time set in parameter

08-12 then the display will show

“OH4” (motor over heat

detection), and the motor will

coast to stop.

2.Motor over heat detection

“OH4” can be reset when the

temperature detection level is

lower than the set level in

parameter【

08-14 PTC reset

】

1.To improve the ventilation

condition

2. Adjust parameter 08-15

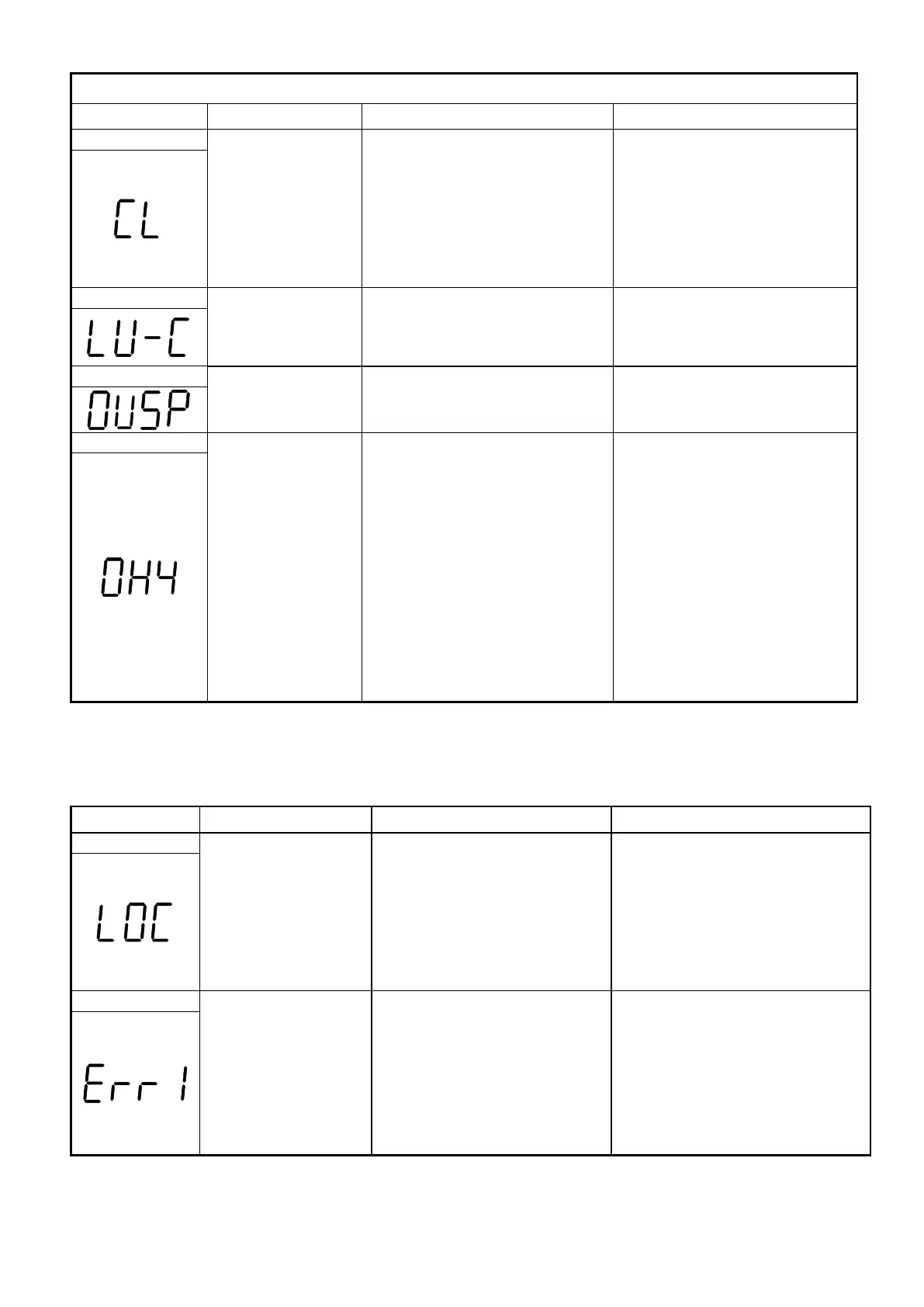

5.1.2 Keypad Operation Error Instruction

1.Parameter

2.Motor direction

locked

3.Parameter

password (13-07)

enabled

frequency parameter while

13-

2.Attempt to reverse

direction when 11- 00=1.

3.Parameter (13 - 07)

enabled, set the correct

1.Adjust 13-06

2.Adjust 11-00

Keypad operation

error

1.Press ▲ or ▼while

00-05/00-06>0 or running

at preset speed.

2.Attempt to modify the

Parameter.Can not be

modified during operation

(refer to the parameter

list)

1.The ▲ or▼ is available for

modifying the parameter only

when 00-05/00-06=0

2.Modify the parameter in

STOP mode.

Loading...

Loading...