514

16/28

Failure to observe these points will lead to

the following dangers:

- Failure of important valve / plant functions

- Failure of prescribed servicing and

maintenance methods

- Endangerment to persons due to electrical,

mechanical and chemical influences

- Endangerment to the environment by

leaking dangerous materials

2 Construction and function

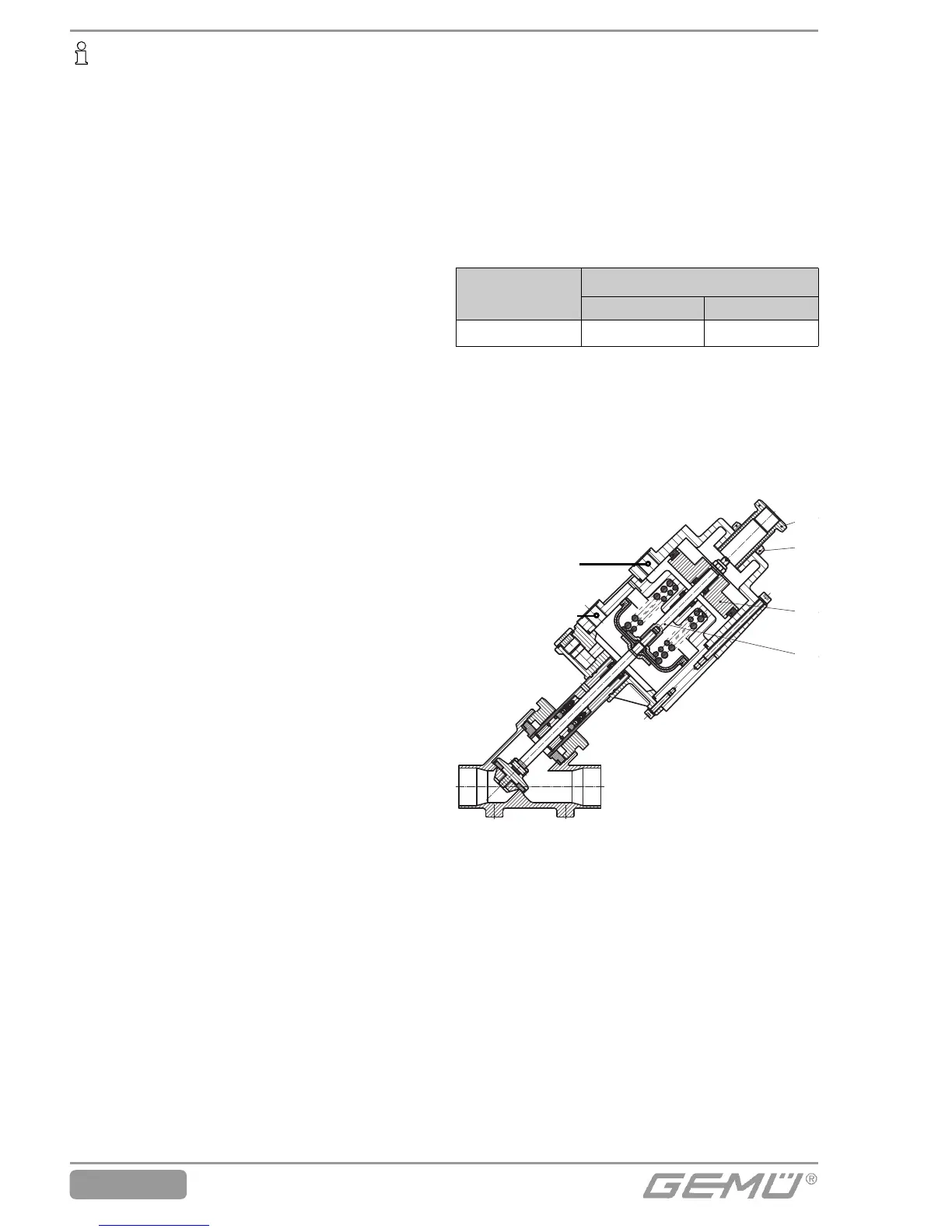

The pneumatically operated 2/2 way valve

is a metal angle seat globe valve with a

straight through body and a low maintenan-

ce aluminium two stage actuator. The

actuator has an aluminium housing and is

controlled by two pistons working indepen-

dently of each other.

Function:

When control pressure (connection V) is

applied, the lower actuator piston strokes

100%. The stroke of the upper part (con-

nection R) of the actuator, however, can be

steplessly limited from 0% to 100% by

means of the stroke limiter (item 40) and

secured by the locking nut (item 41).

When a stroke limiter is used, the actuator

piston (item 39) moves against the stroke

limiter (item 40) and flow restriction is possi-

ble (connection R).

If the lower part of the actuator (connection

V) is under control pressure, the valve fully

opens, pushing the spindle (item 44)

upwards through the upper actuator piston.

The valve bodies are available in various

designs as shown on the data sheet. Diver-

se accessories are available, such as pilot

valves, limit switches and field bus connec-

tions.

The following control function is available:

Control function 1

(normally closed):

Valve resting position: closed by spring

force. For activation of the valve see above.

The valve spindle is sealed by a self-

adjusting gland packing providing low

maintenance and reliable valve spindle

sealing even after a long service life. The

wiper ring fitted in front of the gland packin

protects the seal against contamination and

damage.

Control

function

Connections

V R

1

Full stroke Reduced stroke

40

41

39

44

Connection R

Connection V

IMPORTANT

- The areas of responsibility, the monitoring

of the staff and their competence areas

should be defined precisely by the operator.

- Train staff with insufficient knowledge or, if

necessary, have them trained (by the

manufacturer / supplier on order by the

operator.).

- Ensure that all members of staff under-

stand the safety instructions.

- Keep within the technical data (operating

data) parameters for the valve! It is

available in the technical documentation

(data sheet etc.)

- Define the valve body, sealing material and

lining material, if applicable, according to

the medium. Check its suitability before

installation.

- Adhere to legal regulations!

g

Loading...

Loading...