GENERATOR

RESTRAINT

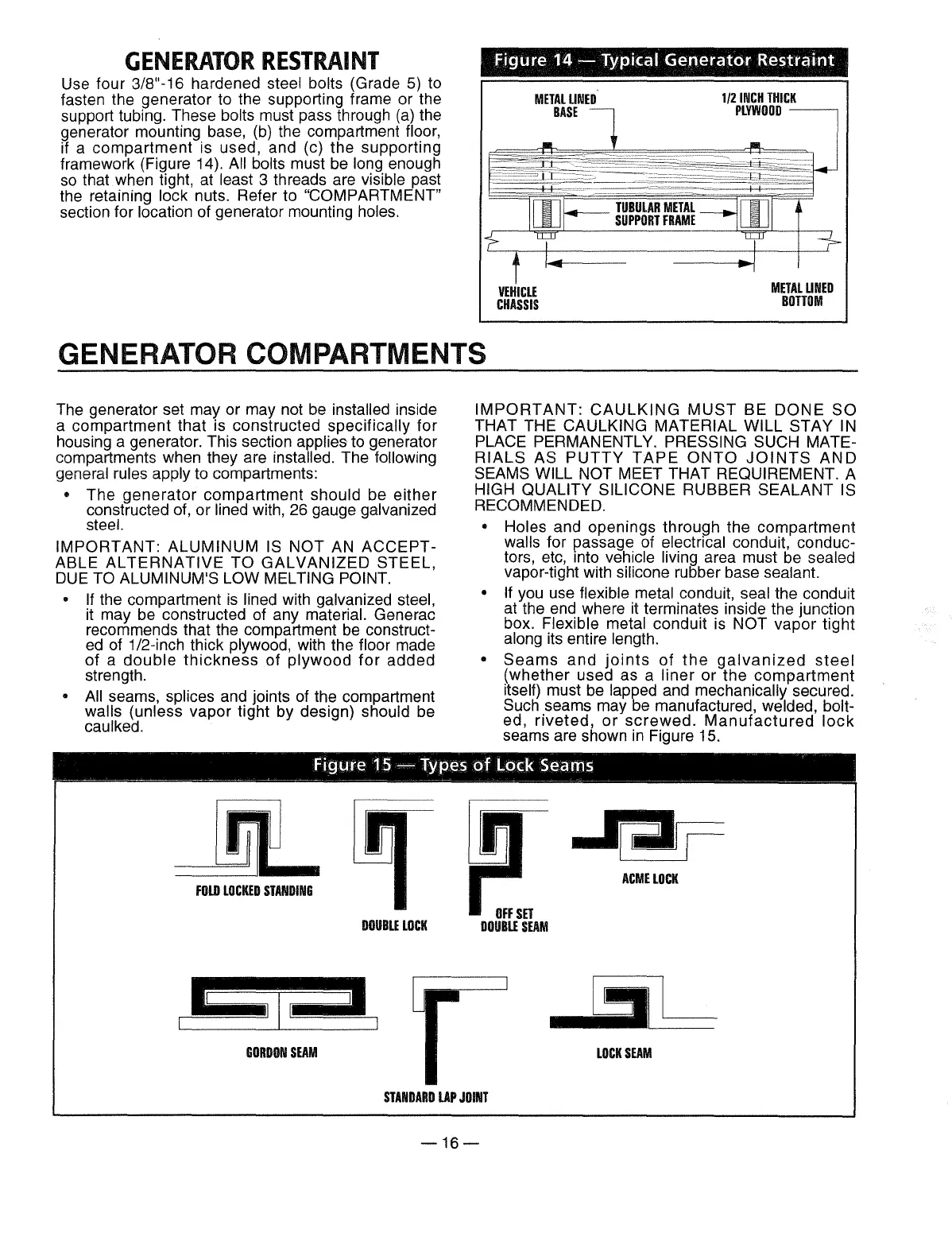

Use four 3/8"-i 6 hardened steel bolts (Grade

5}

to

fasten the generator to the supporting frame or the

support tubing. These

bolts must pass through

(a)

the

generator mounting base,

(b)

the compartment floor,

if a compartment is used, and (c) the supporting

framework (Figure 14).

All bolts must

be

long enough

so

that when tight, at least 3 threads are visible past

the retaining

lock nuts. Refer to "COMPARTMENT"

section for location of generator mounting holes.

Figure

14-

Typical

Generator

Restraint

VEHICLE

CHASSIS

METAL

LINED

BOTTOM

GENERATOR COMPARTMENTS

The generator set may or may not

be

installed inside

a compartment that is constructed specifically for

housing a generator. This section

applies to generator

compartments when they are

installed. The following

general rules apply

to compartments:

• The generator compartment should be either

constructed of, or

lined with, 26 gauge galvanized

steel.

IMPORTANT: ALUMINUM

IS

NOT

AN

ACCEPT-

ABLE

ALTERNATIVE

TO

GALVANIZED

STEEL,

DUE

TO

ALUMINUM'S LOW MELTING POINT.

•

If

the compartment

is

lined with galvanized steel,

it

may

be

constructed of any material. Generac

recommends that the compartment

be

construct-

ed

of

1/2-inch thick plywood, with the floor made

of a

double

thickness

of

plywood

for

added

strength.

•

All

seams, splices and joints

of

the compartment

walls (unless vapor tight by design) should

be

caulked.

IMPORTANT:

CAULKING

MUST

BE

DONE

SO

THAT THE CAULKING MATERIAL WILL STAY IN

PLACE PERMANENTLY. PRESSING SUCH MATE-

RIALS

AS

PUTTY

TAPE

ONTO

JOINTS

AND

SEAMS WILL NOT MEET THAT REQUIREMENT. A

HIGH QUALITY SILICONE RUBBER SEALANT

IS

RECOMMENDED.

• Holes and openings through the compartment

walls for passage of electrical conduit, conduc-

tors,

etc,

mto

vehicle living area must

be

sealed

vapor-tight with silicone rubber base sealant.

•

If

you

use flexible metal conduit, seal the conduit

at the end where it terminates inside the junction

box.

Flexible metal conduit is NOT vapor tight

along its entire length.

•

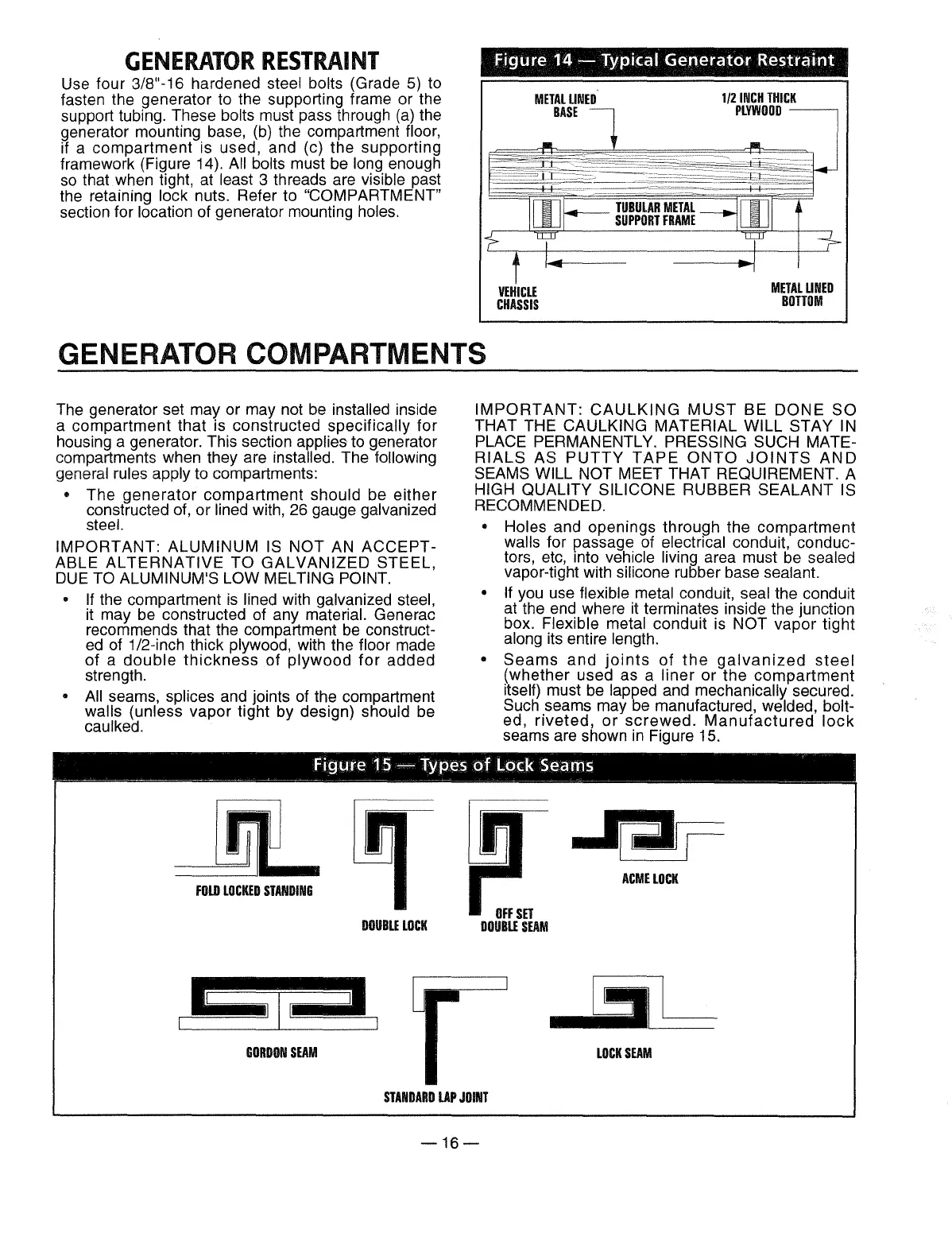

Seams

and

joints

of

the

galvanized

steel

(whether used as a liner or the

compartment

itself) must

be

lapped and mechanically secured.

Such seams may

be

manufactured, welded, bolt-

ed,

riveted,

or

screwed.

Manufactured

lock

seams are shown

in

Figure 15.

Figure

19-

Types

of

Lock Seams

--

---~----~~

---

___f._-

---~

- -

-~---~

- -

--~~-~-----~-

---~~~------

FOLD

LOCKED

STANDING

GORDON

SEAM

DOUBLE

LOCK

OFF

SET

DOUBLE

SEAM

STANDARD

LAP

JOINT

-16-

ACME

LOCK

LOCK

SEAM

Loading...

Loading...