Do you have a question about the Generac Power Systems TOWER LIGHT CUBE+ HYBRID and is the answer not in the manual?

Provides essential safety and operational details about the lighting tower and its compliance with European directives.

Details the company's ISO 9001 certification and commitment to high-quality standards in manufacturing.

Includes the CE Declaration of Conformity and a test certificate confirming machine compliance with directives.

Defines the necessary qualifications, training, and understanding for personnel operating the unit.

Outlines essential pre-operation checks and safety measures, including crowd control and machine status.

Specifies requirements and methods for proper grounding of the unit to ensure electrical safety.

Warns about contact with hot surfaces, engine parts, and floodlights when the unit is operating.

Highlights risks associated with high voltages, bare wires, and wet conditions, providing emergency procedures.

Details hazards related to battery acid, short circuits, and handling tools near batteries.

Advises against removing guards and operating on moving parts, emphasizing appropriate PPE.

Provides safety instructions for refueling operations, prohibiting smoking and emphasizing careful fuel handling.

Recommends using hearing protection when operating the unit due to potential noise exposure.

Warns about the health hazards of exhaust gases and advises maintaining a safe distance from the emission zone.

Provides recommendations for long-term machine storage, including fluid levels and battery disconnection.

Advises on periodic charging of storage batteries to maintain capacity during extended periods of non-use.

Details the specifications of the alternator component, including its model number.

Lists key technical data for the generator, such as power, voltage, frequency, and protection class.

Provides engine specifications, including type, displacement, power, speed, and fuel details.

Details specifications for the hydraulic system, including electrical motor, pump, and fluid.

Outlines the specifications of the lighting tower itself, such as maximum height, rotation, and wind stability.

Provides technical details for the steel cable used for mast raising and lowering operations.

Details the specifications of the batteries powering the floodlights, including voltage, capacity, and cycle life.

Lists the specifications and protection features of the power inverter unit.

Provides technical details for the LED floodlights, including power, luminous flux, and lifespan.

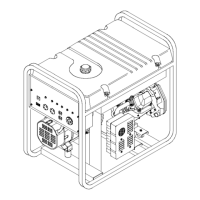

Identifies key external components of the lighting tower through visual diagrams and a parts list.

Identifies components of the external electrical panel, including emergency stop and serial number.

Details and identifies all internal controls, switches, and buttons on the unit's control panel.

Describes the features and benefits of the rechargeable storage batteries used for floodlight power.

Explains the operation and indicators of the electronic battery charger and charging process.

Details the engine starter battery, its connection, and safety precautions for handling.

Describes the hydraulic gear box, including its engine, emergency lowering pin, and oil tank.

Provides instructions for filling the fuel tank, capacity details, and refueling safety precautions.

Explains how to check the engine oil level before starting and after stopping the engine.

Details the procedure for changing the engine oil, including safety warnings and disposal.

Identifies the earthing rod and document holder, and refers to earthing prescriptions.

Describes the methods for moving and transporting the lighting tower, including forklift and lifting hook use.

Provides general advice and warnings for operators, emphasizing safety regulations and qualified personnel.

Details the process of connecting the storage and starter batteries, including switch operation.

Reinforces the importance of correct earthing procedures as outlined in safety regulations.

Lists essential checks to perform before operating the unit, including fluid levels and circuit breakers.

Advises on operating the unit within 70% of maximum power for the first 50 hours for proper engine break-in.

Explains the hybrid system's operation, using generator and batteries to power LEDs efficiently.

Provides guidance on selecting a stable location, ensuring ventilation, and setting up stabilizers.

Describes the various electrical protection devices, including RCDs and circuit breakers for different loads.

Details the different operational modes of the unit, including mains, hybrid, and light sensor controls.

Recommends using specific low-temperature, high-speed bearing grease for roller lubrication.

Advises using WD40 or similar light lubricating oil for mast sections to ensure smooth movement.

Instructs on periodic greasing of stabilizers using dense grease for sliding systems.

Recommends regular inspection of the hydraulic cylinder for wear, damage, or corrosion.

Emphasizes periodic checks of steel cables and pulleys for wear and correct positioning.

Advises on checking hydraulic connections and hoses for leaks, wear, or damage.

Lists common operational problems and their potential causes and remedies, referencing MPnano guide.

| Brand | Generac Power Systems |

|---|---|

| Model | TOWER LIGHT CUBE+ HYBRID |

| Category | Portable Generator |

| Language | English |