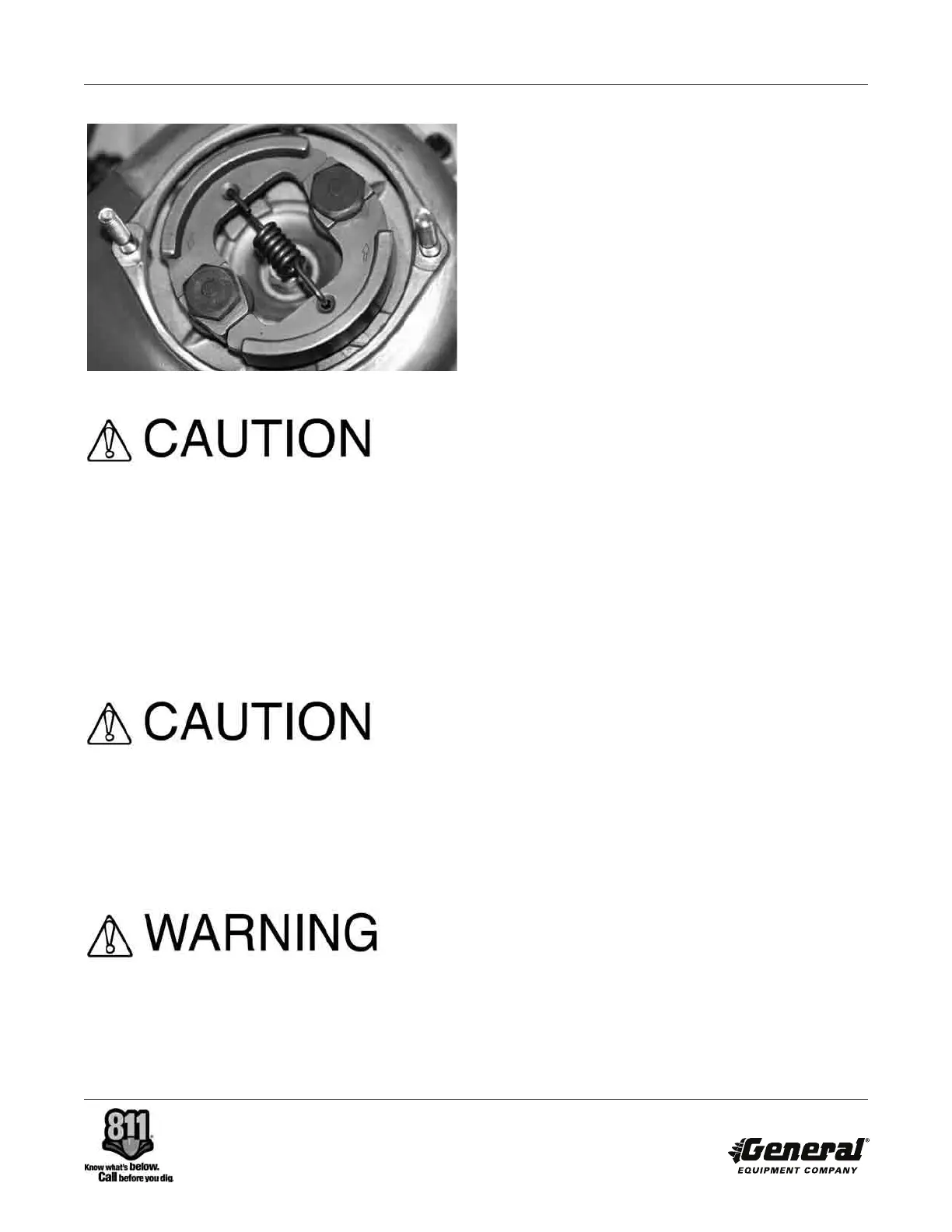

FIGURE 19

Improper orientation will result in increased

slippage, reduced digging capacity with increased

clutch wear.

11) Install the retaining shoulder bolts. Torque the

shoulder bolts to 5.4-7.2 ft. lbs. (7.5-10 N.m.). When

properly installed and torqued, the shoulder bolts

should not thrust directly against the washers and thus

apply a direct force against the clutch shoes. Such an

occurrence will restrict the proper movement of the

clutch shoes.

Improper shoulder bolt clearance will limit proper

movement of the clutch shoes and overall

operation. Such an occurrence can result in

property damage and/or personal injury.

12) Reinstall the engine to the transmission with the

correct orientation to the operator handle.

IMPROPER ENGINE MOUNTING ORIENTATION TO

THE OPERATOR HANDLE CAN REDUCE MACHINE

CONTROL DURING THE HOLE DIGGING

PROCESS. SUCH OCCURRENCE CAN RESULT IN

P RO P E R T Y DA M AG E A N D / O R P E R S O N A L

INJURY.

13) Using the wrench, tighten the 1/4 inch K-lock type

nuts. There is not adequate space to allow the use of a

conventional torque wrench. Tighten the nuts to

approximate a 90 inch pound (10 N.m.) value. An

approximate value will place the nut flush with the end

of the mounting studs.

14) Rotate the final driveshaft and check for excessive

noise and/or binding. If excessive noise and/or binding

is evident, disassemble the engine from the

transmission and investigate for probable causes.

Reassemble and retorque to the specified values.

Recheck again for excessive noise and/or binding.

15) Refill the engine fuel tank and crankcase with the

appropriate fluids as required.

16) If placing the machine back in service, follow the

procedures as outlined in this manual for starting the

engine. Refer to STARTING THE ENGINE WITH THE

AUGER CONNECTED TO THE TRANSMISSION

DRIVESHAFT.

CENT RIFUGAL CL U TCH DRUM AND P INION

SHAFT REMOVAL AND INSTALLATION.

Application: 240H Hole Digger powered by the

Honda GX35 engine.

Tools Required:

2 each, 7/16 inch wrenches

1each, plastic hammer

1 each, powered impact wrench with 12 point, 25/32

inch socket

1 each, torque wrench,120 inch pounds (13.5 N.m.)

capacity.

Parts Required:

1 each, PN 240-0100 gasket

1 each, PN 240-0160 clutch drum and pinion shaft

assembly

1 each, PN 210-0320 pinion gear (if required)

1 each, container of thread anti-seize.

1) Drain the fuel from the fuel tank and oil from the

engine crankcase into UL

®

approved containers. Wipe

any excess spilled liquids and dispose of properly.

240H ONE MAN HOLE DIGGER

FORM GOM14081201, VERSION 1.1

37

Loading...

Loading...