Service and Repair Manual April 2017

Fault Inspection Procedure

166 GS-30 • GS-32 • GS-46 • GS-47 Part No. 1272217

Fault Inspection Procedure

1 Check the device associated with the faulted circuit

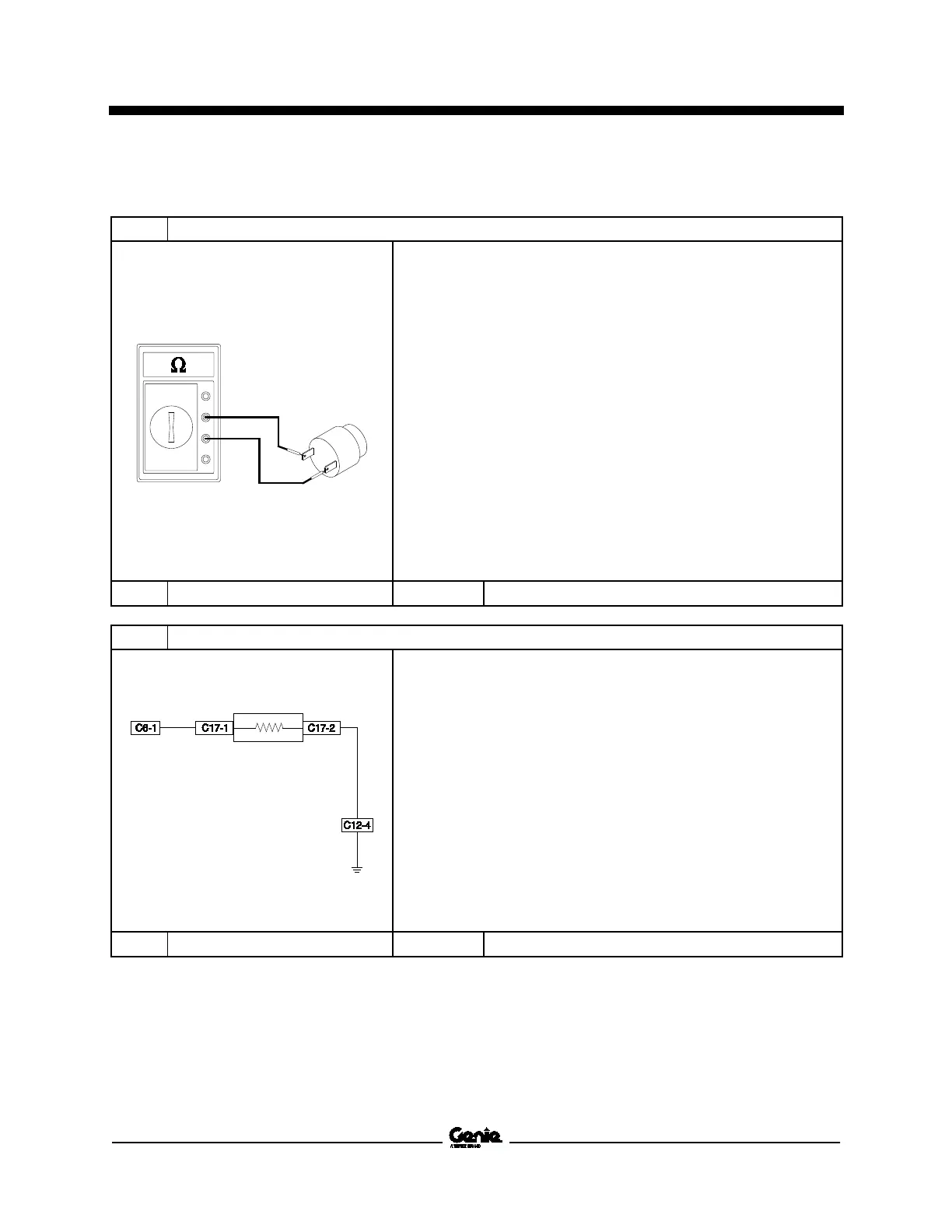

1 Disconnect the faulted device connector.

2 Using a multi-meter, measure resistance between the two

terminals of the faulted device.

3 Resistance should be as follows.

Device Typical Resistance

Solenoid Valve, Drive

27.2 Ω

Solenoid Valve, Steer

19 Ω

Solenoid Valve, Platform Up

25 Ω

Solenoid Valve, Platform Down

6.25 Ω

GCON and PCON Alarm

>1M Ω

Automotive Horn

1.0 Ω

Motor Controller – Enable

5.7k Ω

Motor Controller – Throttle

5.7k Ω

Contactor Coil

47 Ω

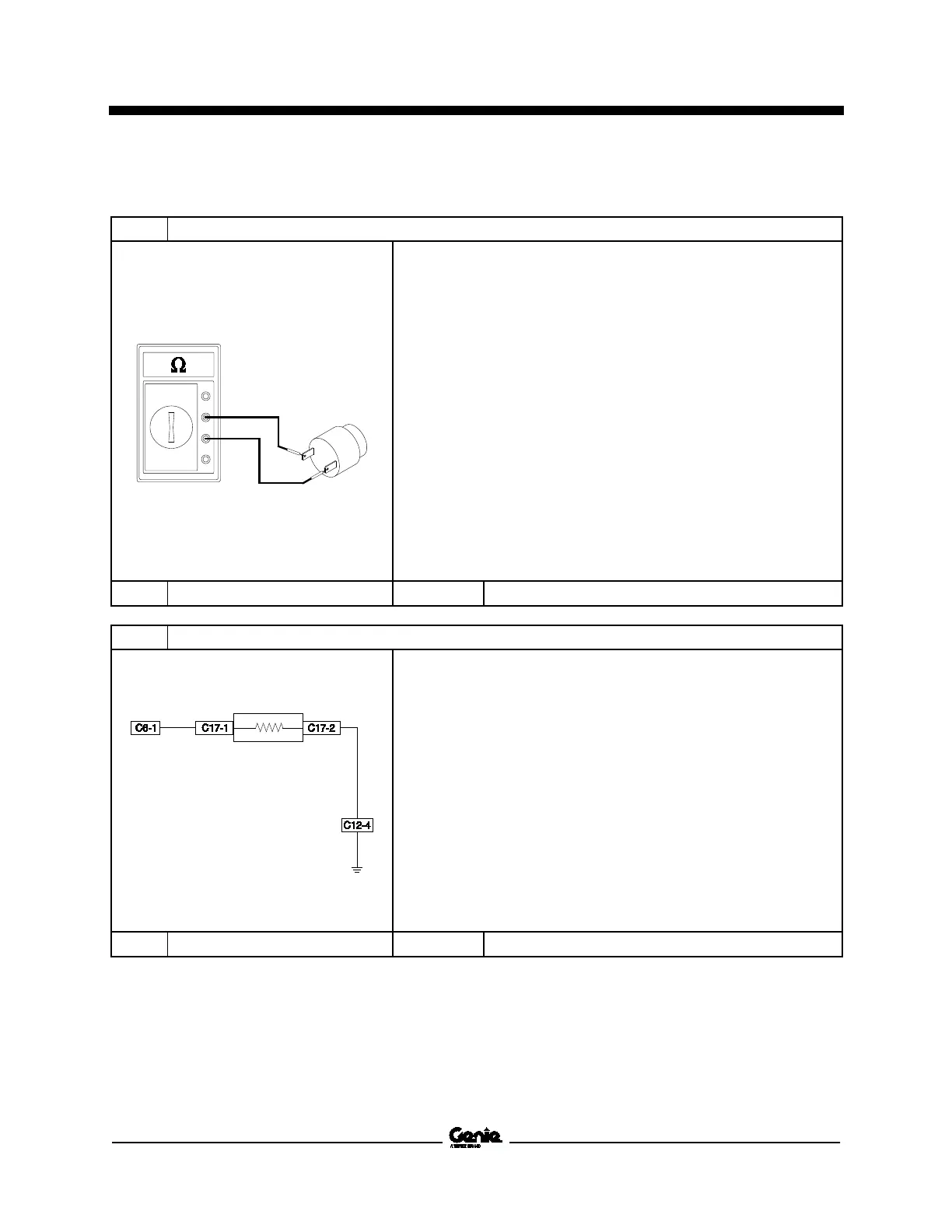

2 Check the harness between the ground controls and the faulted device

1 Disconnect the GCON ECM connectors, J1, J2 and J3.

2 Disconnect the faulted device connector.

3 Check the continuity between the GCON ECM connector

and the signal side of the faulted device.

Result: Resistance should be close to 0 Ω

4 Check the continuity between the return side of faulted

device and system ground.

Result: Resistance should be close to 0 Ω

5 Check resistance between return side and signal side of

the harness plug of faulted device.

Result: Resistance should be 1M Ω or higher.

OK Go to step 3 No Good Replace or repair harness

Loading...

Loading...