16

Electrical connection

To connect the conductivity transmitter, please use a screened, multi-core control cable with a min.

conductor size of 0.5 mm

2

, e.g. LiYCY 4 x 0.5 mm

2

, max. length: 100 m.

Route connecting cables leading to the equipment separate from power cables.

1. Slacken the screws f and remove the housing cover g. The arrow on this cover points to the name

plate. Fig. 1, 9

2. Detach the terminal strip n from the circuit board.

3. Unscrew the cap nut u of the cable gland h and remove the lamellar insert s.

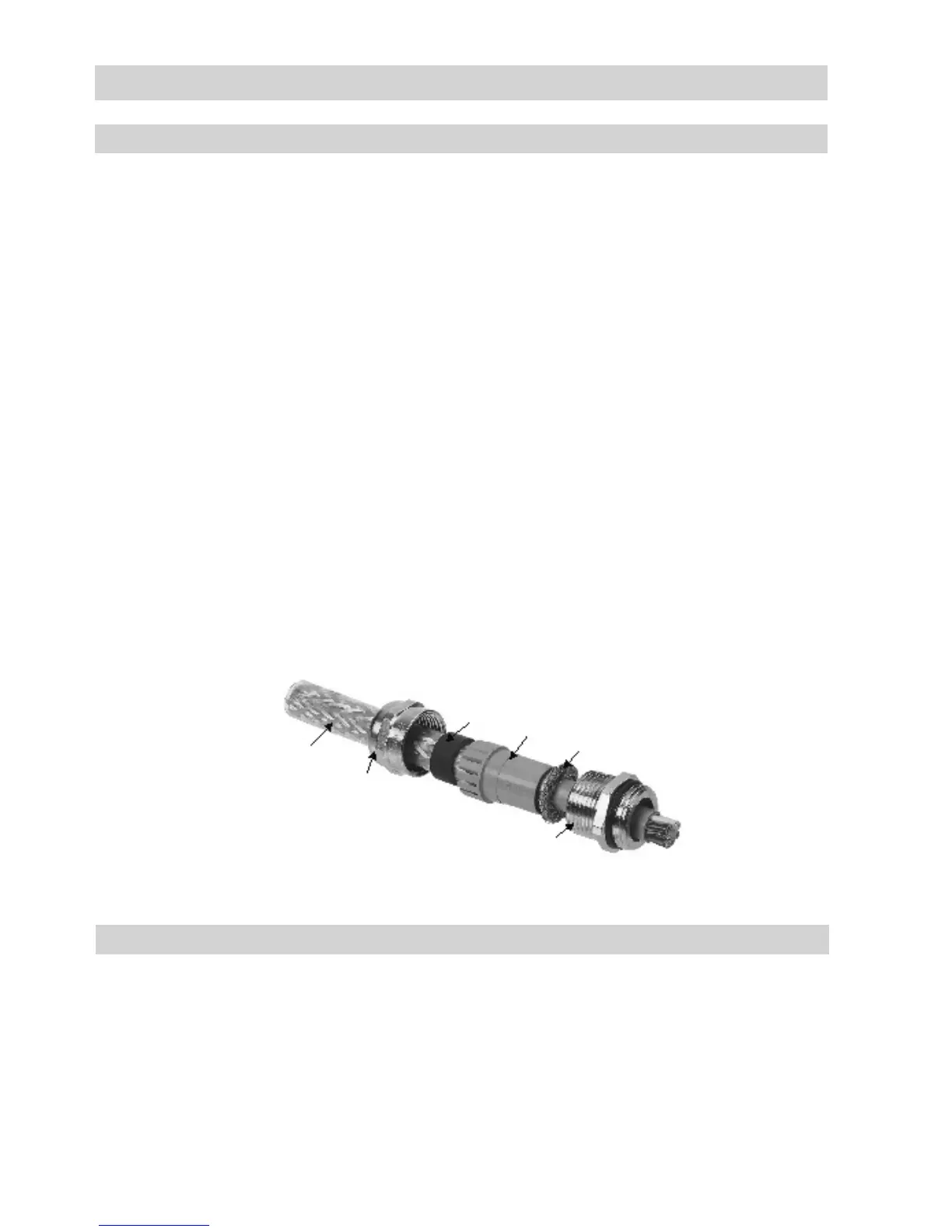

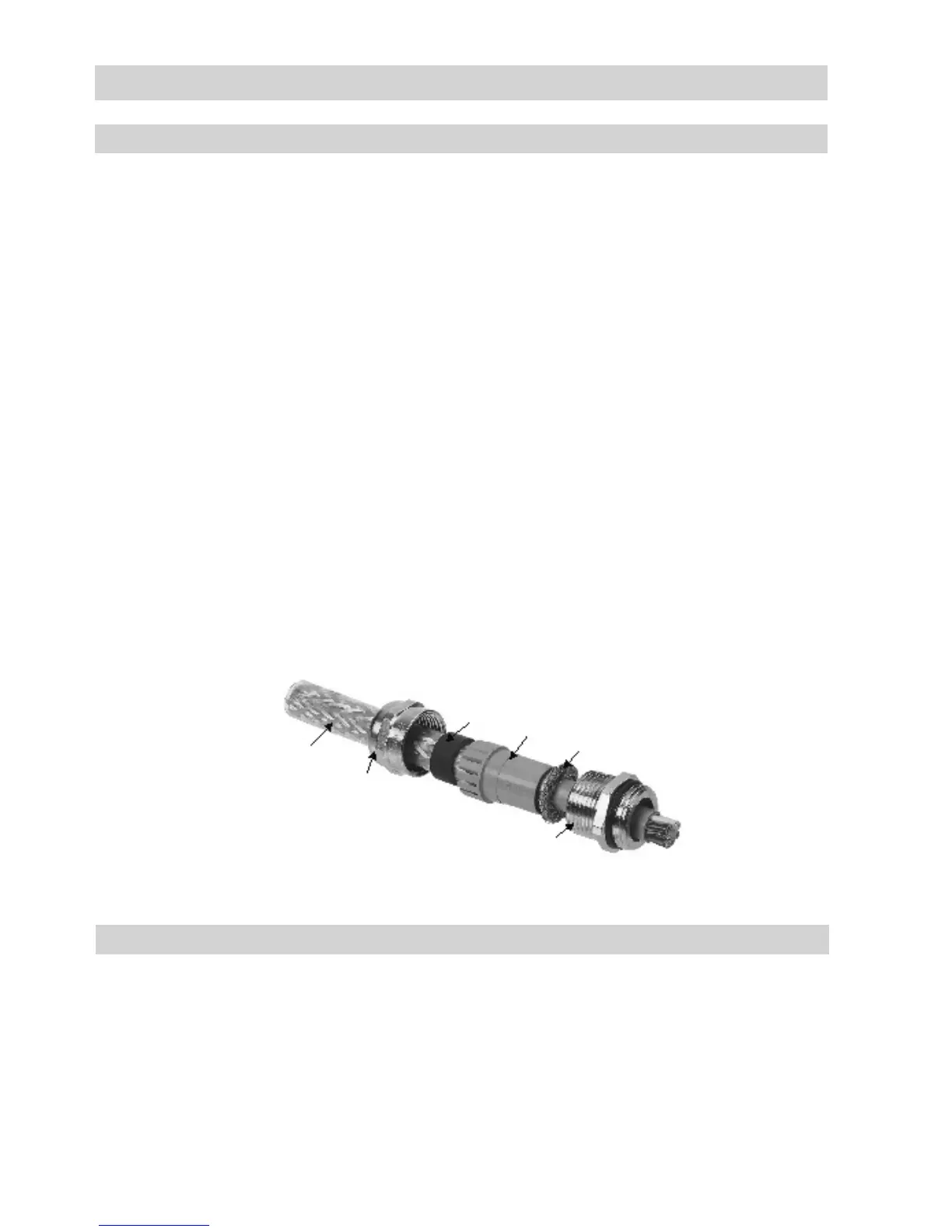

Fig. 11

4. Strip the outer sheath of cable v and expose the braided screen r over a length of

approx. 10 – 15 mm.

5. Push the cap nut u and lamellar insert s with the sealing ring t onto the cable.

6. Bend braided screen r outwards at right angles (90°).

7. Fold the braided screen r towards the outer sheath, i.e. by 180° in total.

8. Push the lamellar insert s with sealing ring t into the gland body q, turn briefly to and fro around

the cable axis and snap anti-rotation element into place.

9. Firmly screw on the cap nut u.

10. Connect the individual cables to the terminal strip n as shown in the wiring diagram.

11. Re-attach the terminal strip n to the circuit board.

12. Replace the cover g and fasten the cover screws f.

Connecting LRGT 16-1, LRGT 16-2, LRGT 17-1

continued

Fig. 11

t

r

q

v

u

s

Key

j Code switch

m Terminal lugs for electrode wires,

functional earth

n Terminal strip

p Connection for functional earth

q Gland body

r Braided screen

s Lamellar insert

t Sealing ring

u Cap nut

v Screened cable

Loading...

Loading...