PROCESS DESCRIPTION

PROCESS DESCRIPTION

Steam is generated in the sterilizer through an external

water feed that may be preceded by a softening filter.

Condensation is led off to the drain.

PRE-TREATMENT (1)

The purpose of pre-treatment is to remove air from the

chamber and from the goods. Air prevents the requi-

site contact between the steam and micro-organisms

to be killed.

Pre-treatment consists of steam injection and evacua-

tion pulses in different processes depending on the

program selected. In addition, the humidification es-

sential to killing mainly takes place during the pre-

treatment stage.

STERILISATION (2)

Sterilisation takes place by maintaining the saturated

steam's relation (boiling point at a specific pressure).

The sterilisation phase is in progress during a pre-

programmed number of minutes at the preselected

temperature/pressure.

POST TREATMENT (3)

The purpose of post treatment is to reduce the mois-

ture content in the goods. During post treatment the

pressure drops to atmospheric pressure or lower –

depending on the selected program. Post treatment is

completed by air being drawn in until the chamber is

at atmospheric pressure.

STANDARD PROCESSES

NAME PARAMETER AREA STANDARD

P1 Instrument 134 °C Sterilisation temperature

Sterilisation time

Post treatment

5 - 180 min

5 - 180 min

134°C

5 min

5 min

P2 Instrument 121 °C Sterilisation temperature

Sterilisation time

Post treatment

5 - 180 min

5 - 180 min

121°C

20 min

5 min

LIQUID PROCESS (EXTRA)

NAME PARAMETER AREA STANDARD

P3 Liquid 121 °C Sterilisation temperature

Sterilisation time

Post treatment

5 - 180 min

121°C

20 min

Cooling to 95 °C

Customised processes are possible.

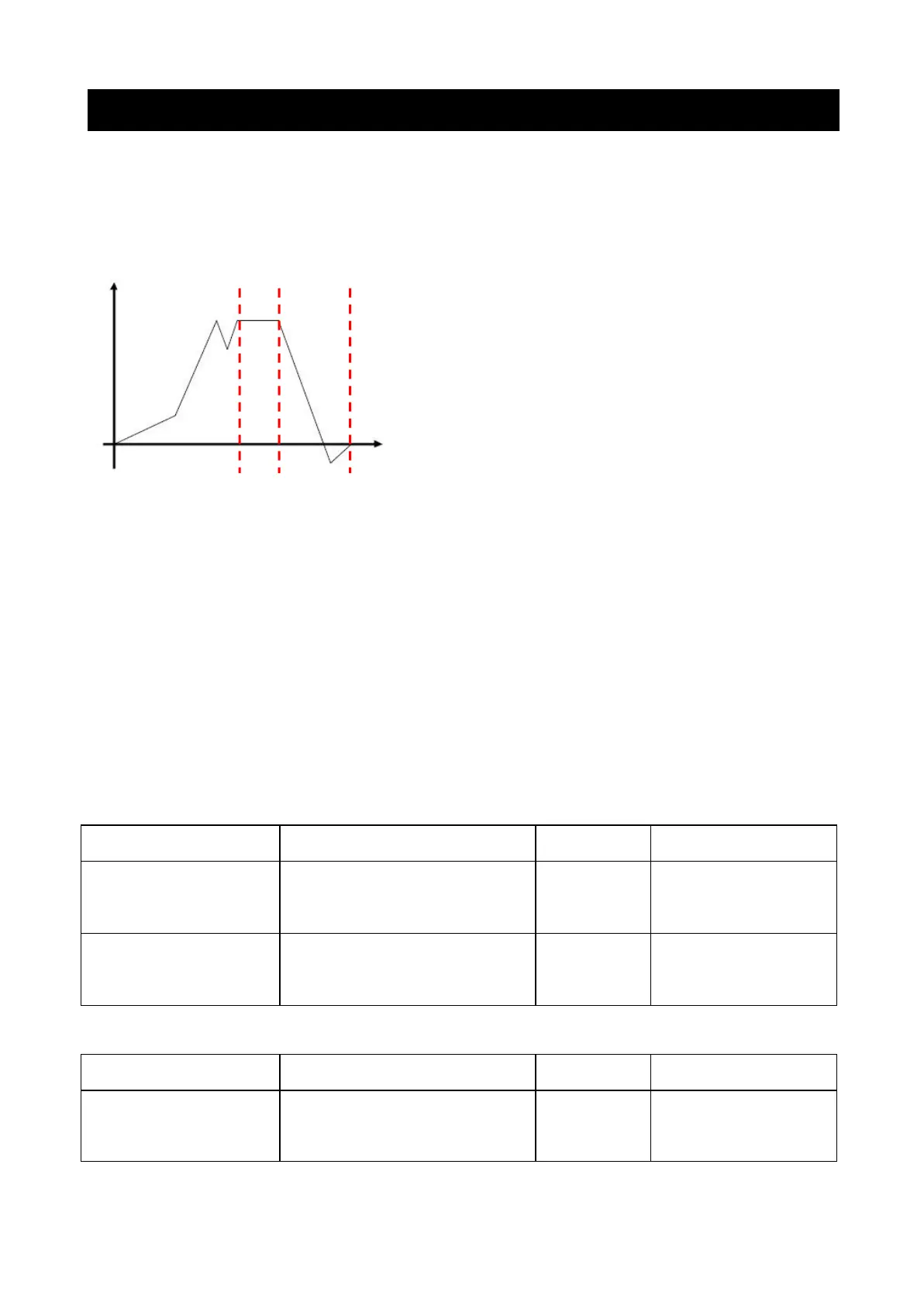

General Pressure/Time graph for a process

1. 2. 3.

Loading...

Loading...