24

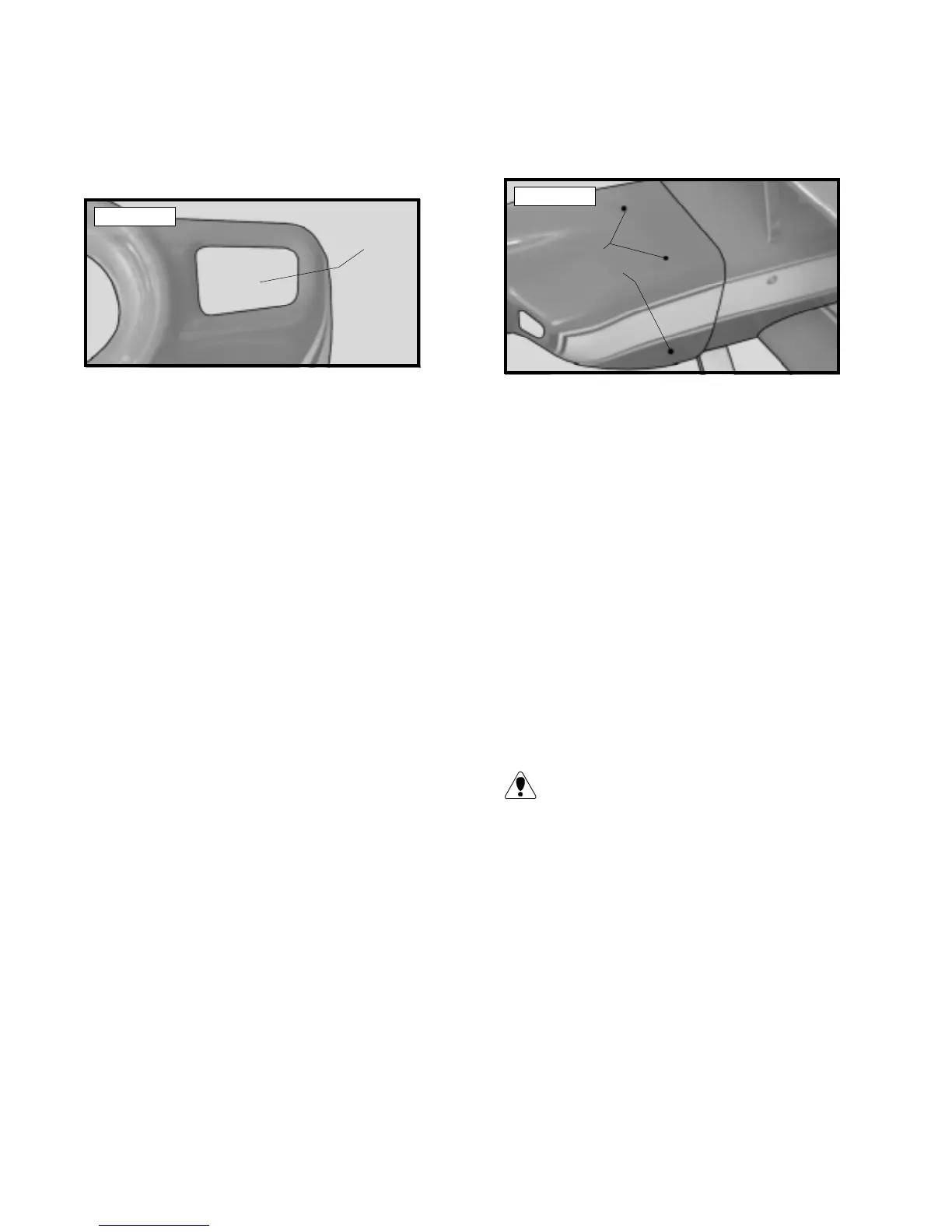

o2) Using a Dremel Tool with a sanding

drum attachment, carefully open the two air

inlets in the front of the cowl. Trim away a

small amount at a time so you don't remove

too much material. See photo # 41 below.

Photo # 41

o 3) Slide the cowl onto the fuselage. In-

stall your spinner backplate onto the en-

gine and secure it in place. Use the

backplate to align the front of the cowl.

The spinner backplate diameter should

match the outer diameter of the spinner ring

on the cowl, not fit inside it. It may also

be necessary to trim the bottom of the cowl

so it does not interfere with the landing

gear.

o 4) With the front of the cowl aligned

with the spinner backplate, double check

that the cowl lines up with the fuselage.

When satisfied with the fit, use a couple of

pieces of masking tape to hold the cowl

firmly in position.

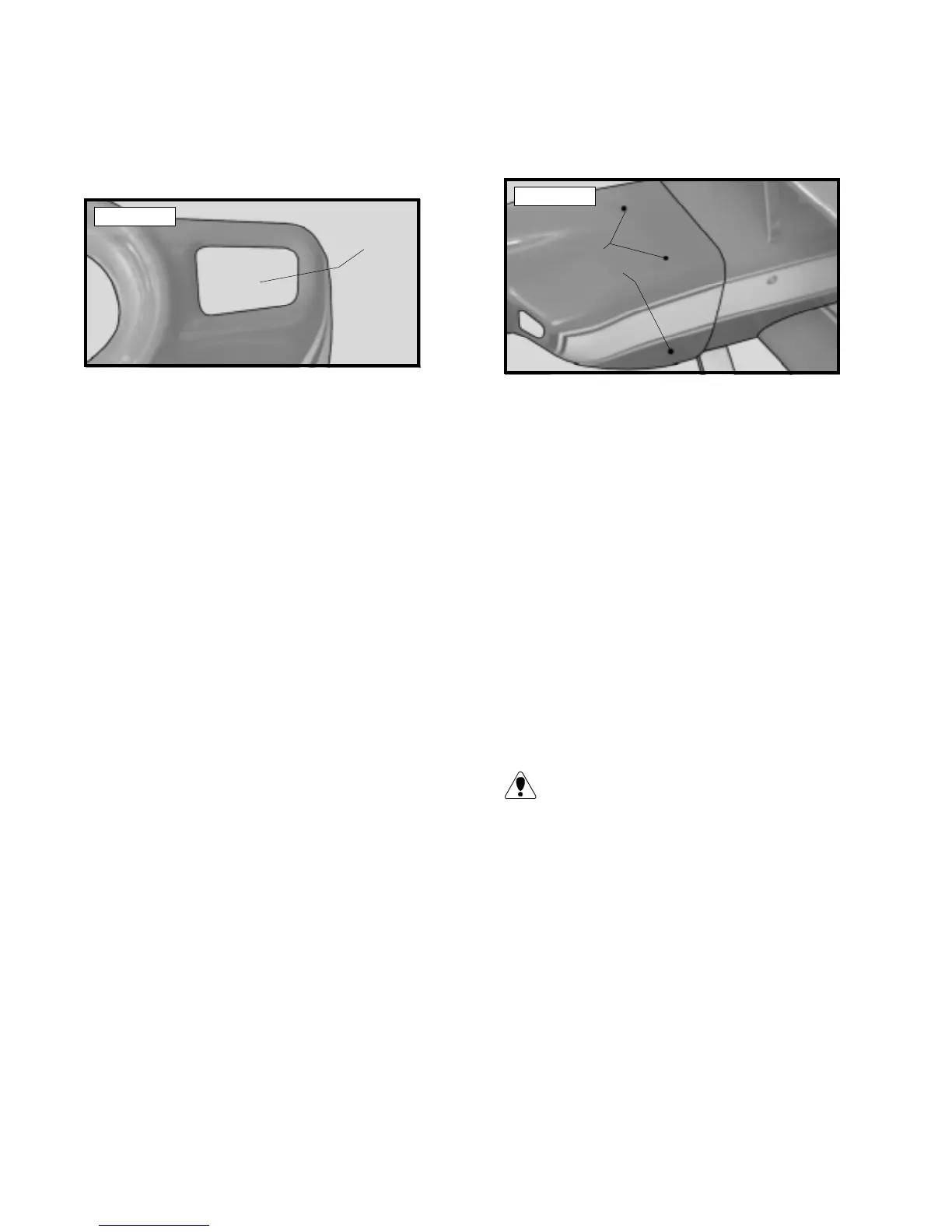

o 5) The cowl is held in place using four

3mm x 6mm wood screws threaded into the

firewall. Two screws are located on the

top, one on each side towards the bottom

of the cowl. Use a ruler and pen to locate

and mark the mounting screw locations.

o 6) Using a 1/16” drill bit, drill four pi-

lot holes through the cowl and about 1/2”

into the firewall at the locations you

marked.

Photo # 42

o 8) Locate and the areas of the cowl that

need to be removed for access to the high and

low speed needle valves, glow plug, muffler

and if necessary, engine head clearance.

o 9) Remove the cowl and make these cut-

outs using a Dremel Tool with a sanding drum

attachment. Holes for the needle valves can

be cut using a drill bit. We highly suggest the

use of a Dubro Fuel Filler Valve to fuel the

airplane. This should be mounted to the cowl-

ing at this time also.

o 10) Install your muffler (stock or Pitt's

Style) and connect your fuel and pressure lines

to the fuel tank and fueling valve.

If you are using a two stroke engine with

a stock muffler a 1” muffler extension

will be necessary. No extension is necessary

if using a four stroke engine or a two stroke

engine with an aftermarket Pitt's Style muf-

fler.

o 11) Once you are satisfied with the fit of

the cowl and all access holes have been cut,

remove the cowl and paint it with Coverite

21st Century Gloss Clear # COVR1265 to pre-

vent raw fuel from damaging the paint.

o 12) After the clear coat has dried, connect

the fuel lines to the muffler, fuel filler valve

and carburetor. Reinstall the cowl and secure

it in place. Install the prop and spinner.

MAKE

CUT OUT

(BOTH SIDES)

o 7) Remove the cowl and enlarge the holes

in only the cowl using a 5/64” drill bit. Rein-

stall the cowl and secure it in place using the

four wood screws. See photo # 42 below.

MOUNTING HOLE

LOCATIONS

Loading...

Loading...