Supplied By www.heating spares.co Tel. 0161 620 6677

7

221504A

2 Water System

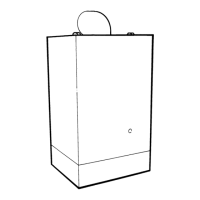

Diagram 2.2OPEN VENTED SYSTEM

Open (vented) system.

Recommended

relationship between

pump, cold feed and

vent.

22 mm (MIN) VENT

FEED AND

EXPANSION

CISTERN

15mm (MINIMUM)

COLD FEED

15mm (MINIMUM)

BY-PASS WITH

LOCKSHIELD VALVE

450mm

MIN.

HEIGHT

1150mm

MIN.

150

mm

MIN.

BOILER

PUMP

150mm

MAX

FLOW

RET.

ALTERNATIVE

PREFERRED

RET.

CYLINDER

FLOW

HEATING

0005M

Notes: Open Vented and Sealed Systems

See chart for pressure drop of the boiler diagram 2.1.

2.1 Draining Tap

The boiler is provided with a draining tap at the lower left hand

side of the heat exchanger, to be used for draining the heat

exchanger.

A draining tap must be provided at the lowest points of the

system which will allow the entire system and hot water cylinder

to be drained.

Draining taps shall be to the current issue of BS2879.

2.2 Safety Valve

A safety valve need not be fitted to an open vented system.

2.3 Circulating Pump

The pump should be fitted in the flow pipe from the boiler and

have isolating valves each side, integral if possible.

A variable duty pump should be set to give a temperature

difference of 11

0

C (20

o

F) between the flow and return with the

thermostat set at “MAX” which is about 82

o

C (180

o

F), to give a

design flow rate as shown in Table 3.

High resistance microbore systems may require a higher duty

pump.

2.4 Bypass

A BYPASS MUST BE FITTED, see diagram 2.2 for a suitable

position.

The flow rate through the boiler must not be allowed to fall below

that given in Table 4.

Where the water system can allow the boiler and pump to

operate on bypass only, a bypass

must be placed at least 1.5m

away from the boiler.

2.5 Inhibitor

Attention is drawn to the current issue of BS5449 and BS7593

on the use of inhibitors in central heating systems.

If an inhibitor is to be used, contact a manufacturer for their

recommendations as to the best product to use.

If using in an existing system take special care to drain the entire

system, including the radiators, then thoroughly flushing out

before fitting the boiler whether or not adding inhibitor.

TABLE 4.

MINIMUM FLOW RATE at MAX OUTPUT

MODEL 60F 16.4L/min 3.6gal/min

TABLE 3.

DESIGN FLOW RATE at MAX OUTPUT

MODEL 60F 23.0L/min 5.1gal/min

PRESSURE LOSS OF BOILER

1.5

1.0

0.5

0

50

40

30

20

0

0

5

10 15

20 25 30

Flow rate (litres/minute)

Water pressure loss

(metres head of water)

Water pressure loss

(inches head of water)

10

60

01

2

3

4

56

Flow rate (gallons/minute)

35 40

70

78

2.0

0164M

Diagram 2.1

22mm (MINIMUM)

BY-PASS WITH

LOCKSHIELD VALVE

2.6 Open (Vented) Water System

For an open (vented) system the boiler must be supplied from

an unrestricted water supply taken from a feed and expansion

cistern situated at a maximum height of 27.5metres (90ft)

above the boiler.

The cold feed supply must be 15mm minimum size.

The vent must rise continuously and be unrestricted.

It is important that the relative positions of the pump, cold feed

and open vent are as shown in diagram 2.2.

Loading...

Loading...