38

12 Servicing

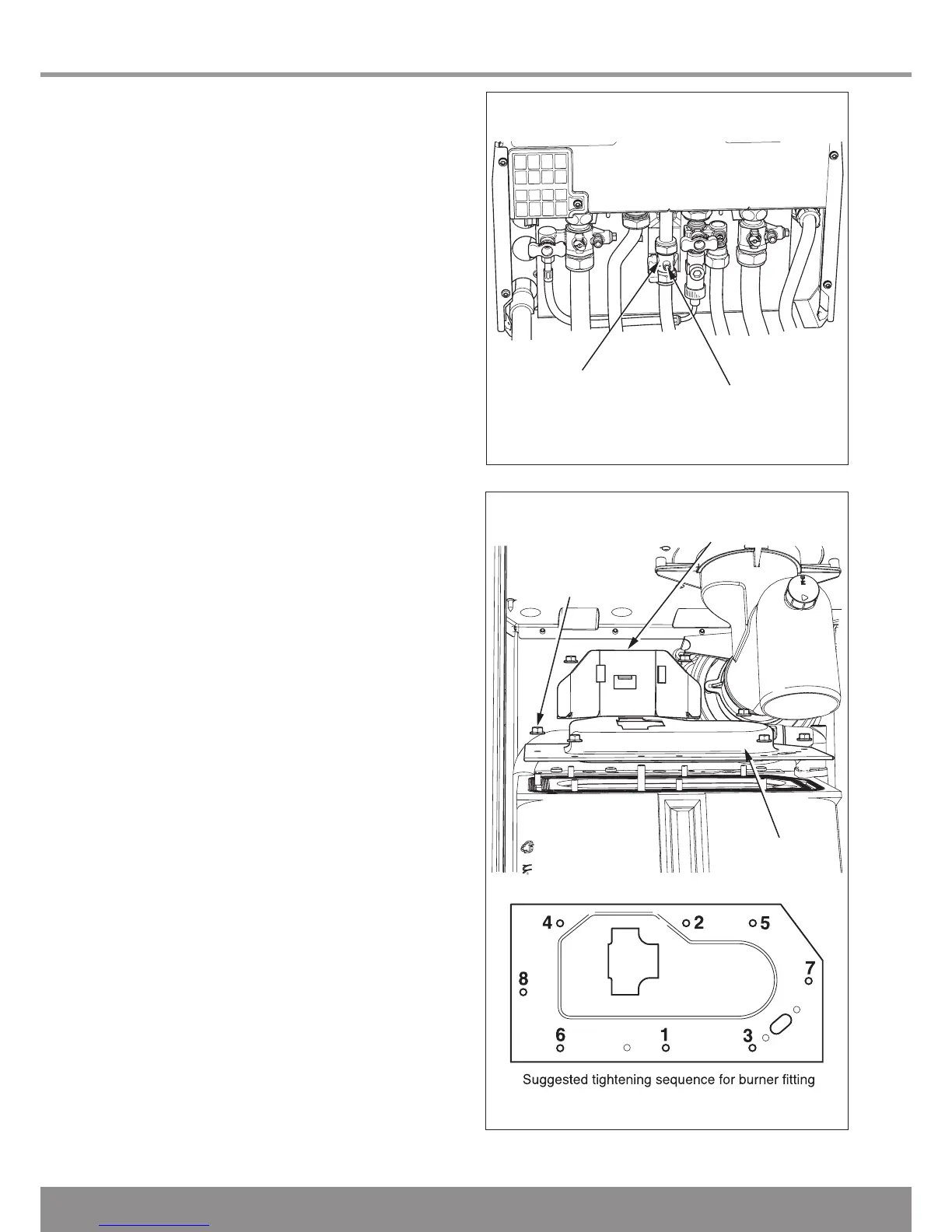

Diagram 12.1

Important Notes

To ensure the continued efficient and safe operation of the

boiler it is recommended that it is checked and serviced at

regular intervals. The frequency of servicing will depend upon

the particular installation and usage, but in general once a

year should be enough.

It is the Law that any servicing is carried out by a competent

person.

When replacing a part on this appliance, use only spare parts

that you can be assured conform to the safety and perform-

ance specification that we require. Do not use reconditioned

or copy parts that have not been clearly authorised by Glow-

worm.

12.1 General

Measurement of the products of combustion can be achieved

by connection of a probe to the combustion analyser test point

on the flue elbow, see diagram 12.3 and section 12.6.

IMPORTANT NOTE:

Products of combustion will be dis-

charged when the cap is removed. It is important to replace

the cap immediately.

Testing Flue Gases: If any doubt exists that the flue prod

-

ucts are not exhausting correctly, investigate by use of a gas

analyser (FGA).

Before commencing with a service or replacement of parts

the boiler should be isolated from the electrical supply and the

gas supply should be turned off at the gas service cock, see

diagram 12.1.

All routine servicing requirements can be achieved by the

removal of the front panel. Remove the two screws on the

underside of the front panel and lift off.

For access inside the appliance a Torx T20 drive is required

or alternatively a flat blade screwdriver can be used.

Unless stated otherwise any part removed during servicing

should be replaced in the reverse order to removal.

Servicing should always include the removal of any debris

from the condensate pipe and siphon.

After completing any servicing of gas carrying components,

ALWAYS test for gas soundness and carry out a functional

test of the controls.

12.2 Flue Hood

Pull the flue hood securing clips away from the flue hood

sump and push flue hood up slightly towards flue hood top,

see diagram 14.6.

To remove swivel flue hood 90

0

and pull down and out to-

wards front of boiler, see diagram 14.7.

Check seal for wear or damage and replace if necessary.

13014

Loading...

Loading...