48

221469B

4.16 Gas Valve - Honeywell

Before starting refer to Section 1.1.

Isolate the boiler from the electrical supply and close the gas

service cock, refer to Section 1.3.

Remove the outer case, refer to Section 1.4.

Remove the control housing, refer to Section 4.7 paragraph 7.

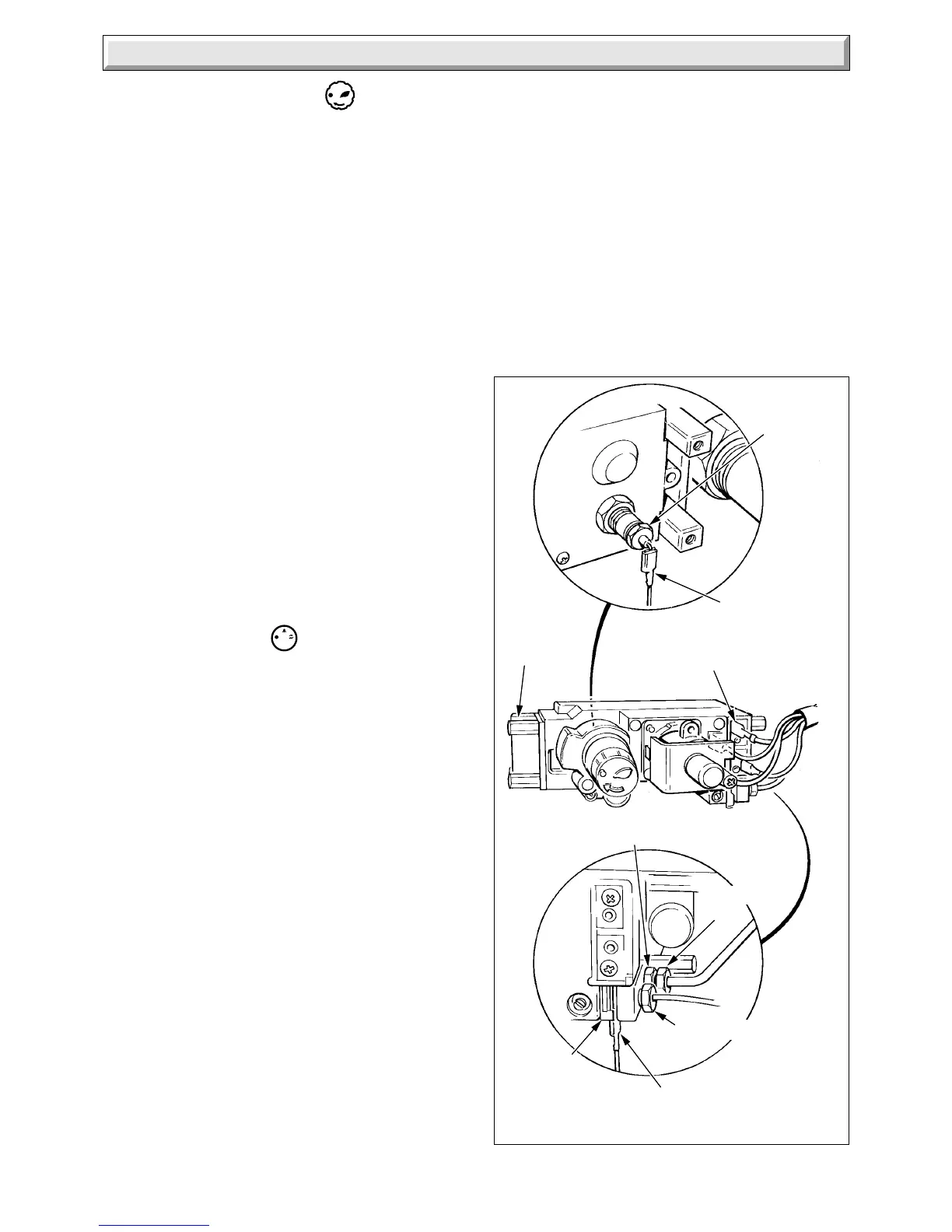

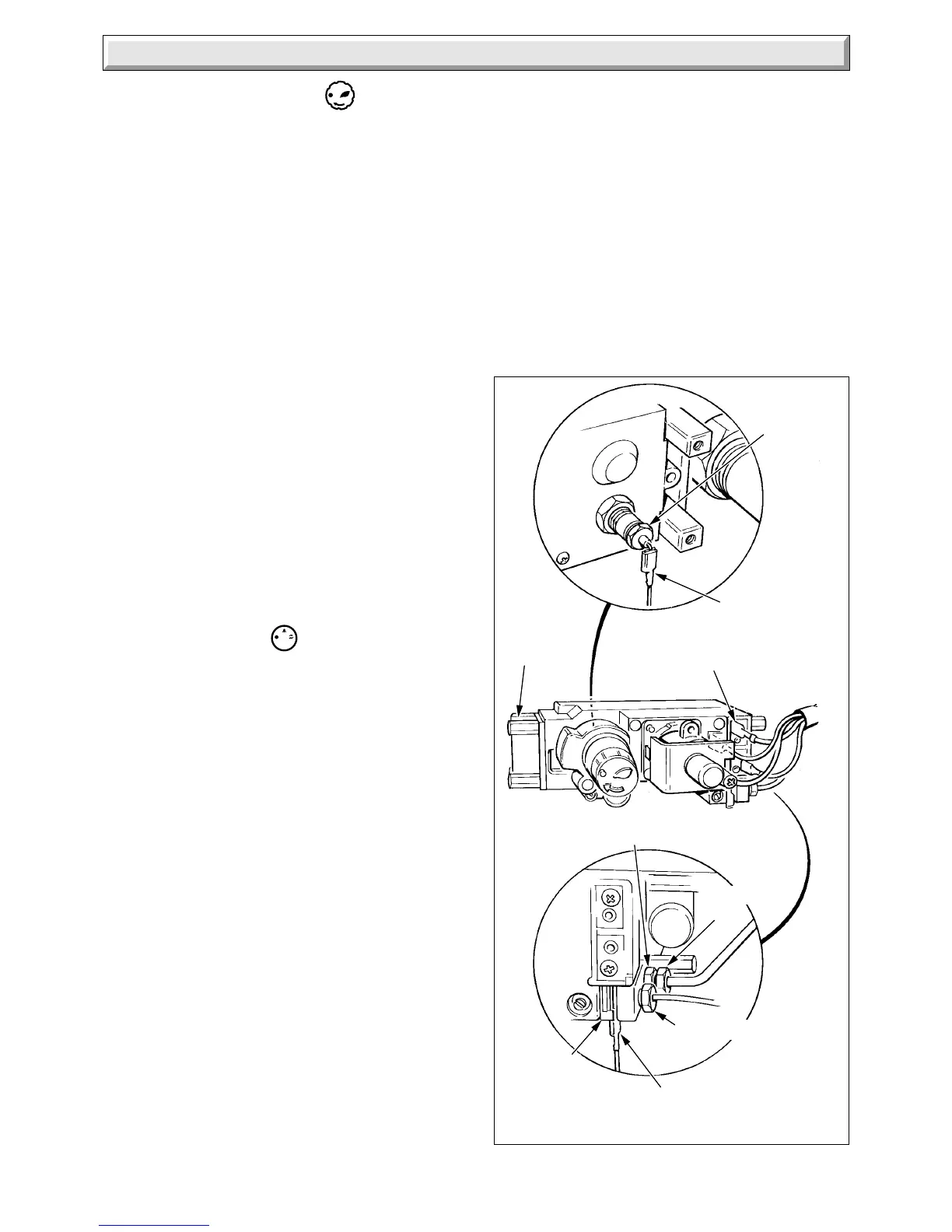

Remove the piezo unit bracket, see diagram 4.12.

Disconnect the five electrical connectors, four at the front of the

gas valve and one at the rear, see diagram 4.11.

Disconnect the thermocouple at the gas valve.

Disconnect the pilot supply tube at the gas valve.

Remove the four extended hexagon screws at the right of the

valve.

Support the gas valve, disconnect the union nut of the gas

service cock and remove the valve complete with inlet pipe.

Separate the valve from the pipe, noting the fitted position.

Transfer the pilot tube adapter and the overheat cutoff connectors

to the replacement valve.

Discard the “O” rings and fit the new ones supplied, when fitting

the gas valve.

To connect the gas valve cables correctly, see diagram 4.10.

Light and adjust the boiler if necessary, refer to Commissioning

in the Installation Instructions. Adjust the pilot flame if necessary,

refer to Section 4.4, Pilot Burner.

Check and adjust the main burner pressure in the hot water and

central heating modes, refer to Commissioning in the Installation

Instructions.

4.16 Gas Valve - SIT

Before starting refer to Section 1.1.

Isolate the boiler from the electrical supply and close the gas

service cock, refer to Section 1.3.

Remove the outer case, refer to Section 1.4.

Remove the control housing, refer to Section 4.7, paragraph 7.

Remove the piezo bracket, see diagram 4.12.

Disconnect the four electrical connectors at the front of the gas

valve and the boiler overheat cutoff connectors, see diagram

4.11.

Disconnect the thermocouple at the gas valve.

Disconnect the pilot supply tube at the gas valve.

Remove the four extended hexagon screws at the right hand of

the gas valve.

Support the gas valve, disconnect the union nut of the gas

service cock and remove the valve complete with inlet pipe.

Separate the valve from the pipe. noting the fitted position.

Discard the “O” rings and fit the new ones supplied.

To connect the gas valve cables correctly, see diagram 4.10.

If necessary adjust the pilot flame, refer to Section 4.4.

Check and adjust the main burner gas pressure in both the hot

water and central heating mode, refer to Commissioning in the

Installation Instructions.

4 Replacement of Parts

HONEYWELL

Diagram 4.11

2276 S

OVERHEAT

CUT-OFF

CONNECTOR

ELECTRICAL

CONNECTOR

ELECTRICAL

CONNECTOR

OVERHEAT

CUT-OFF

CONNECTOR

PILOT TUBE

ADAPTOR

SECURING

SCREW

(4 + 4)

ELECTRICAL

CONNECTORS (4)

THERMOCOUPLE

NUT

PILOT TUBE

NUT

4.17 Central Heating Selector Switch

Before starting refer to Section 1.1

Isolate the boiler from the electrical supply and close the gas

service cock, refer to Section 1.3.

Remove the outer case, refer to Section 1.4.

Slacken the piezo bracket securing screws and remove the

bracket from the keyhole slots, see diagram 4.12. Take care

not to strain the piezo and electrical leads.

Pull the leads off from the switch, see diagram 4.12.

To remove the switch press the retaining tabs at the sides.

The polarity of the electrical connections is not important.

Loading...

Loading...