1 0991 497 EN - 24.03.2017

3010 ¾” VALVE MANUAL

INSTALLATION, USE AND MAINTENANCE

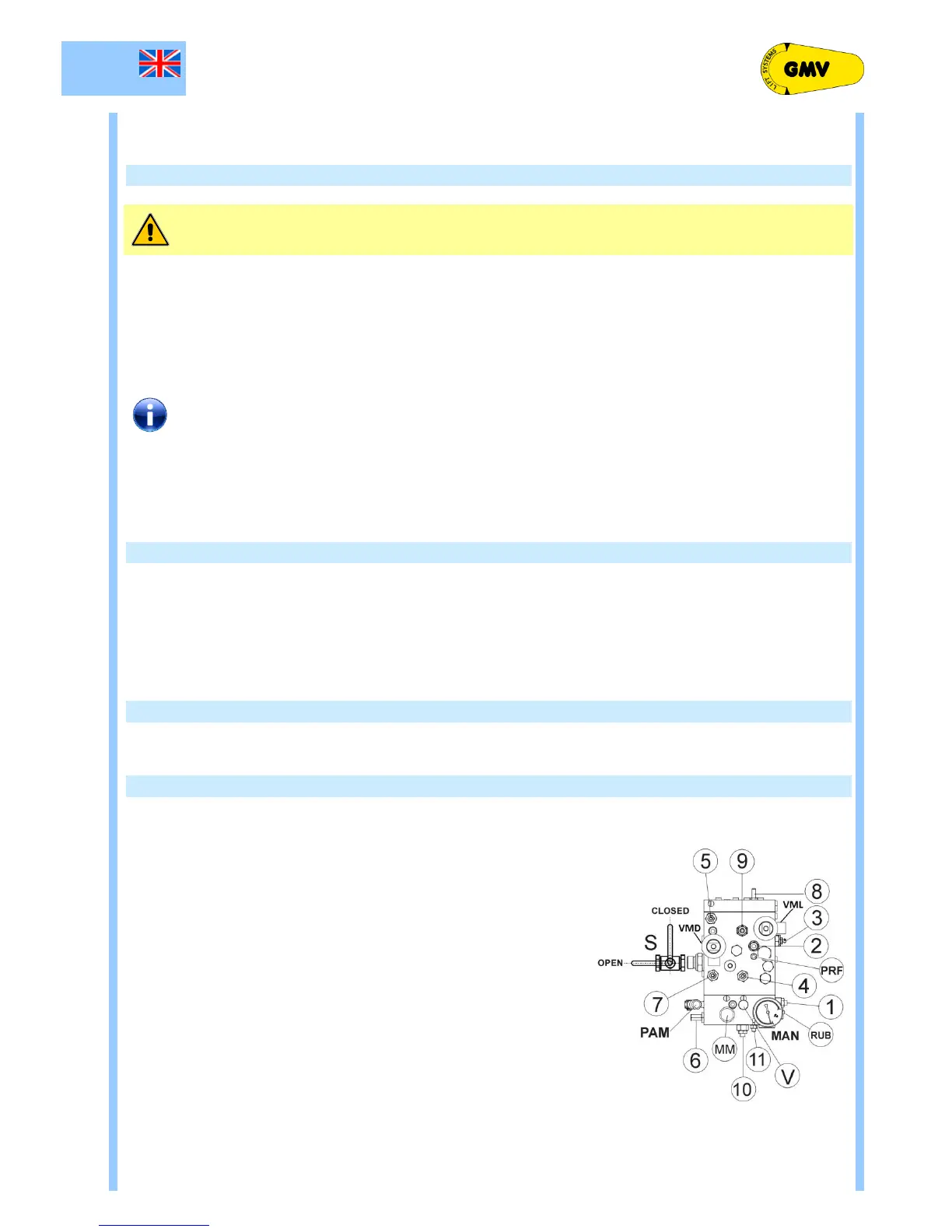

- Tighten the lock nut (3).

- The adjustment is finished.

3.9 PIPE RUPTURE VALVE (VC) TEST (IN THE VALVE BLOCK) – N° 5

WARNING

Before doing this test, the pipe rupture valve mounted on the piston should be adjusted (refer to VC

manual)

- Send the car with full load to the highest floor.

- Once the car has stopped.

- Loosen the lock nut (5) to test the rupture valve

- Completely tighten the screw n.5 .

- Call the car to the lowest floor.

- The test is finished.

NOTE:WHEN THE CAR DOWNWARD SPEED MATCHES THE INTERVENTION FLOW,THE

RUPTURE VALVE CLOSES TO STOP THE CAR (IN CASE OF BY-PASS RUPTURE VALVE,THE

CAR LOWERING CONTINUES SLOWLY).IN CASE THE RUPTURE VALVE DOES NOT

CLOSE,FOLLOW THE FACTORY INSTRUCTIONS TO REDUCE ITS INTERVENTION SPEED TO

BE ABLE TO RESTART THE TEST.

- Completely loosen the n.5 .

- During the standard car downward we do not have any intervention of the rupture valve

- Completely tighten the lock nut (5).

- The test is finished.

3.10 ADJUSTMENT OF THE MINIMUM RAM PRESSURE, VSMA (2:1 SYSTEMS) N° 6

Only in installations with traction 2:1.

- Close the ball valve (S).

- Press the manual lowering button (MM) to release pressure.

- Check the pressure on the manometer (MAN) is around 6 bar.

- If the pressure it not correct, adjust screw (6).

- The adjustment is finished.

3.11 MANUAL LOWERING OPERATION (EMERGENCY ONLY) – BUTTON (MM)

- Press the manual lowering button (MM) to send downward the car to the unlock door area

-

3.12 ADJUSTMENT OF THE MAXIMUM PRESSURE - HAND PUMP

- Close the ball valve (S).

- Verify that the suction tube is immersed in the oil.

- Loosen the screw (V) two or three turns to bleed the air.

- Push the lever several times till the oil starts flowing through the

screw (V).

- Tighten the screw (V) completely.

- Loosen the lock nut (10)

- Loosen the screw (10) two or three turns.

- Open the shut-off valve for pressure gauge exclusion (RUB).

- Push the hand pump lever to reach the maximum pressure,

adjust the screw (10) till the value is 2,3 times the full load

pressure (refer to the lift technical report).

-

Example:

If full load pressure is 35 bar, screw (10) should be adjusted to:

35 x 2,3 = 80,5

- When the pressure is correct.

- Tighten lock nut (10).

- Open the ball valve (S).

- The adjustment is finished.

Loading...

Loading...