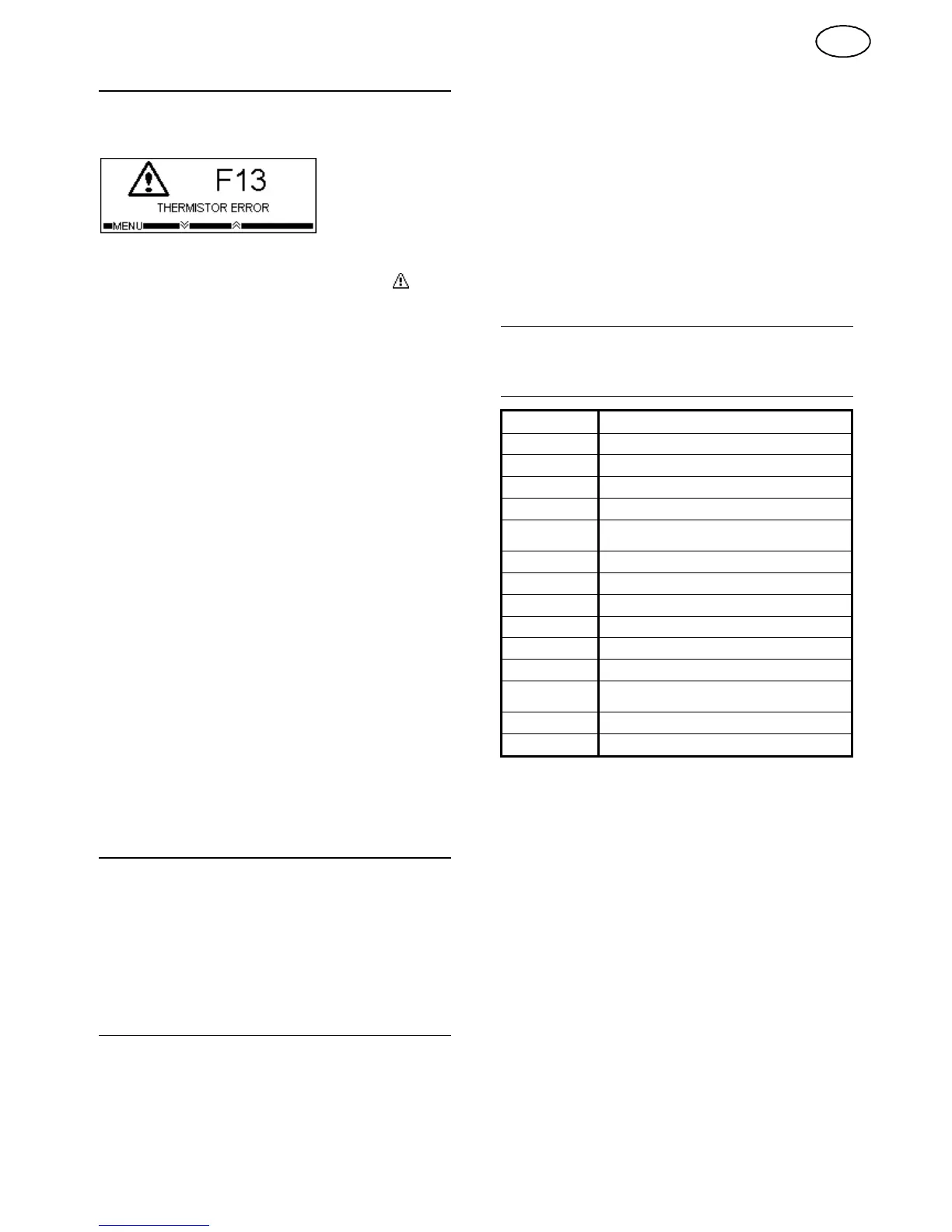

Faults / Warnings

If a fault occurs during charge the charge status indicator will show

indication 5 and the LCD display will show a

fault code and

description, for example:

Faults permanently stop charge until they are rectified.

If a warning occurs during charge the warning symbol

will be

displayed on the LCD display and the warning code and

description can be accessed by scrolling through the charge

information.

Warnings do not affect the charge procedure.

Fault Codes

F06

No output current

F07

**Incorrect battery

F09

**Bulk charge timeout

F10

**Gassing charge timeout

F12

Configuration error

F13

Thermistor fault

F16

**Battery over temperature

F17

**Auto balance timeout

F18

Battery disconnected

F19

Battery disconnected during cooldown

F20

Battery thermistor error

F21

Over current

F27

Slave 1 incorrect current

F28

Slave 2 incorrect current

F29

Slave 3 incorrect current

F30

Slave 1 temperature fault

F31

Slave 2 temperature fault

F32

Slave 3 temperature fault

Warning Codes

F01

**Over discharged battery

F02

**Deeply

discharged battery

F03

**Sulphated battery

F04

Charger overheating

(Becomes a fault if overheating persists)

F05

Mains failed during charge

F14

**Watering overdue

(Becomes a fault after 5 cycles)

F23

Batt ID PCB error

F24

Batt ID antenna error

F25

Batt ID tag read error

F26

Batt

ID not programmed

Repair

Only suitably qualified personnel should perform repair work

on this equipment.

Use of genuine factory sourced replacement parts is necessary to

ensure CE marking is not invalidated.

Contact your local maintenance facility for assistance or spares,

quoting the charger type and serial number which can be found on

the identification label.

Maintenance

Before carrying out maintenance, isolate the mains supply

and disconnect the battery.

Only suitably qualified personnel should perform

maintenance work on this equipment.

The charger will require little maintenance, but the following

schedule is recommended once a month:

(a)

Check the condition of all cables, paying particular

attention to the points where cables may be severely

flexed, i.e. at the entry to charger cabinet, charging plugs

and sockets.

(b)

Check condition of charging plugs and sockets for wear

and any evidence of overheating, which could ultimately

lead to charger malfunction.

(c)

Check that ventilation is not obstructed.

(d)

Ensure that all safety covers and panels are correctly in

place.

GNB I.P.

recommends that a yearly periodic inspection / test is

performed on this equipment, contact your local agent for details.

Guarantee

See local conditions of sale.

Specification

Input Voltage

1PH - 230VAC 10% ±

3PH - 400VAC 10% ±

Input Frequency

45 –

66Hz

Input Current

Model dependant -

Specified on charger rating plate

Input Cable

2 meters of flexible PVC cable to BS6500

(Input plug fitted on request)

Input Protection

Replaceable fuse(s)

fitted inside the cubicle

Charge

Characteristic***

Microprocessor controlled –

HP = S, D, L, H, G & F, , C, R Z

LP

= S, D, F & C

Output Voltage***

Model dependant –

24, 36, 48, 72 & 80V Only

Output Cable

2.9

meters of heat, oil resistant & flame retardant cable to

BS6195

Output Current***

Model dependant -

20

to 300A

Output Protection

Replaceable fuse inside the cubicle

IP Rating

IP21

Cooling

Thermostatically controlled fan

Ventilation

Chargers must be positioned with at least 200mm of

clearance overhead, with the fan and front vents

unobstructed

Ambient

temperature

0 –

35

o

C

User Interface

High visibility tri-colour charge status indicator, 192 x 64

Graphic LCD & 5 push buttons

^

Not available / shown for LP version

*

Optional Item, additional hardware may be required.

**

These faults are usually associated with the battery, check

battery condition.

***

Factory set as ordered, stated on rating plate

5

GB

Loading...

Loading...