Commander III

2-45

the ignition switch to the start position to crank the

engine.

C20

Continuous exposure to engine and machine

noise can cause hearing injury. Do not operate the

machine without adequate hearing protection.

Notice: Do not operate the starter longer than 30

seconds at a time or damage will result. Allow 2

to 3 minutes between starting attempts to allow

starter to cool.

Crank the engine until it starts. If the engine does not

start after 15 to 20 seconds of cranking, release the

ignition switch. Wait 2 to 3 minutes between starting

attempts to allow the starter to cool.

360909

The fault/standby lamp on the control box will be on.

Press and release the fault reset switch ( ). If the

fault/standby lamp remains on, check the active faults

menu and reset or repair the fault(s). If the lamp is

ashing, the controller is in standby mode and is ready

for operation.

Increase engine speed to 1500 rpm and allow the

engine to warm for 10 to 15 minutes before activating

any function.

To move the machine, or to load or unload it, increase

engine speed to maximum. Use the manual jog

switches to raise the machine high enough to clear

obstacles. Press the run/standby switch to place the

controller in the run mode. The fault/standby lamp

should stop ashing and turn off. Refer to the previous

paragraphs if the fault/standby lamp does not turn off.

Note: To hold the machine frame level, adjust

the slope setpoint to read “0.00”. Place the slope

auto/manual switch in the auto “A” position. The

machine frame cross slope will automatically

remain level while moving the machine. It may

be necessary to adjust the sensitivity, if the

machine reacts erratically. Refer to the sensitivity

adjustment procedures in section 06.

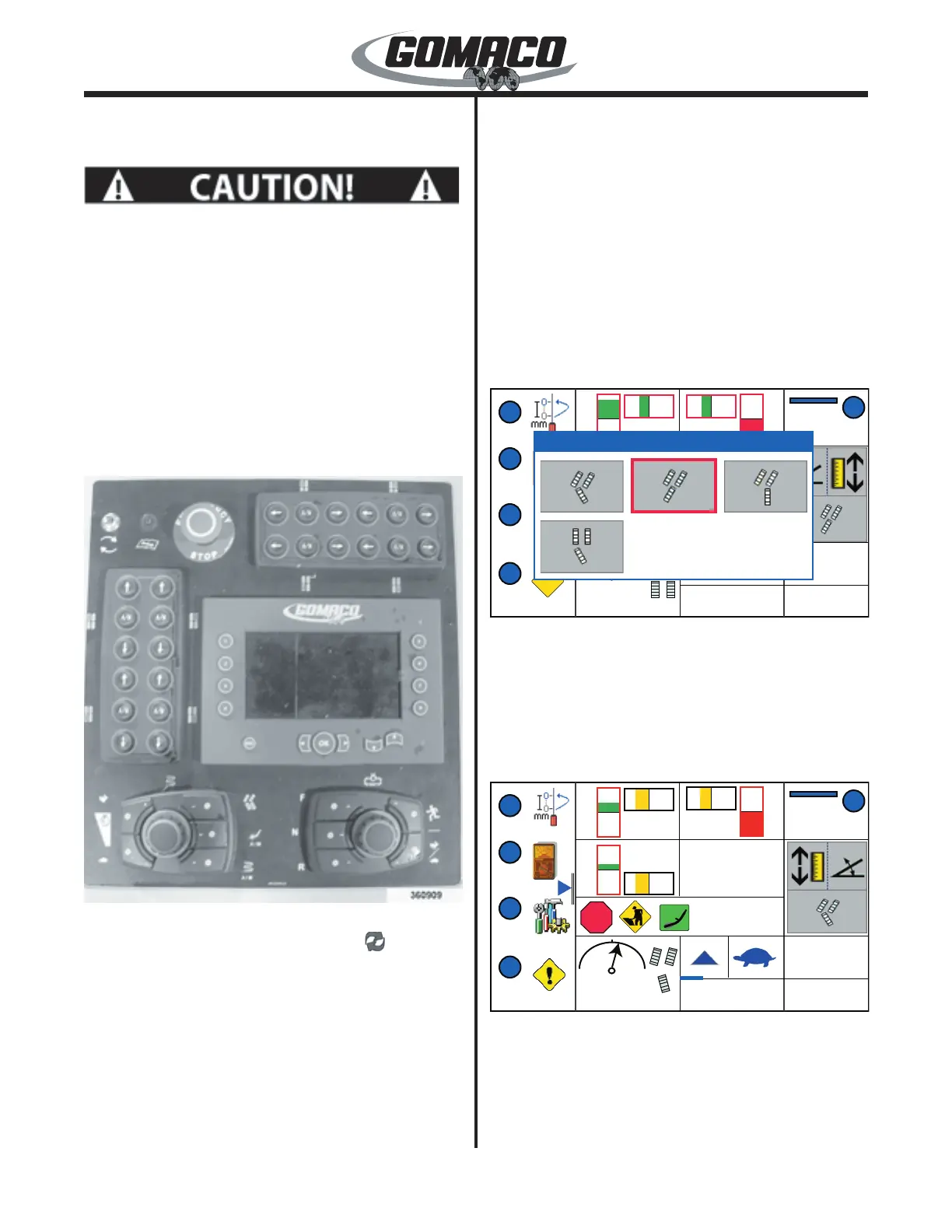

061G+

1

2

3

4

5

M M

M

M

M

M

M M

0.00%

ft/min

E-STOP

!

Steer Mode

061G+

Place each steer auto/manual control loop in

automatic mode as indicated on the Run Menu. Press

and release the manual steer switch until the desired

manual steer mode is selected. Rotate the manual

steer dial to steer the track(s) in the desired direction.

Make certain the track(s) are correctly positioned

before moving the machine.

059G+

1

2

3

4

5

A

M

M

M

A

A

0.00%

ft/min

E-STOP

059G+

▼

Loading...

Loading...