SERVICING

30

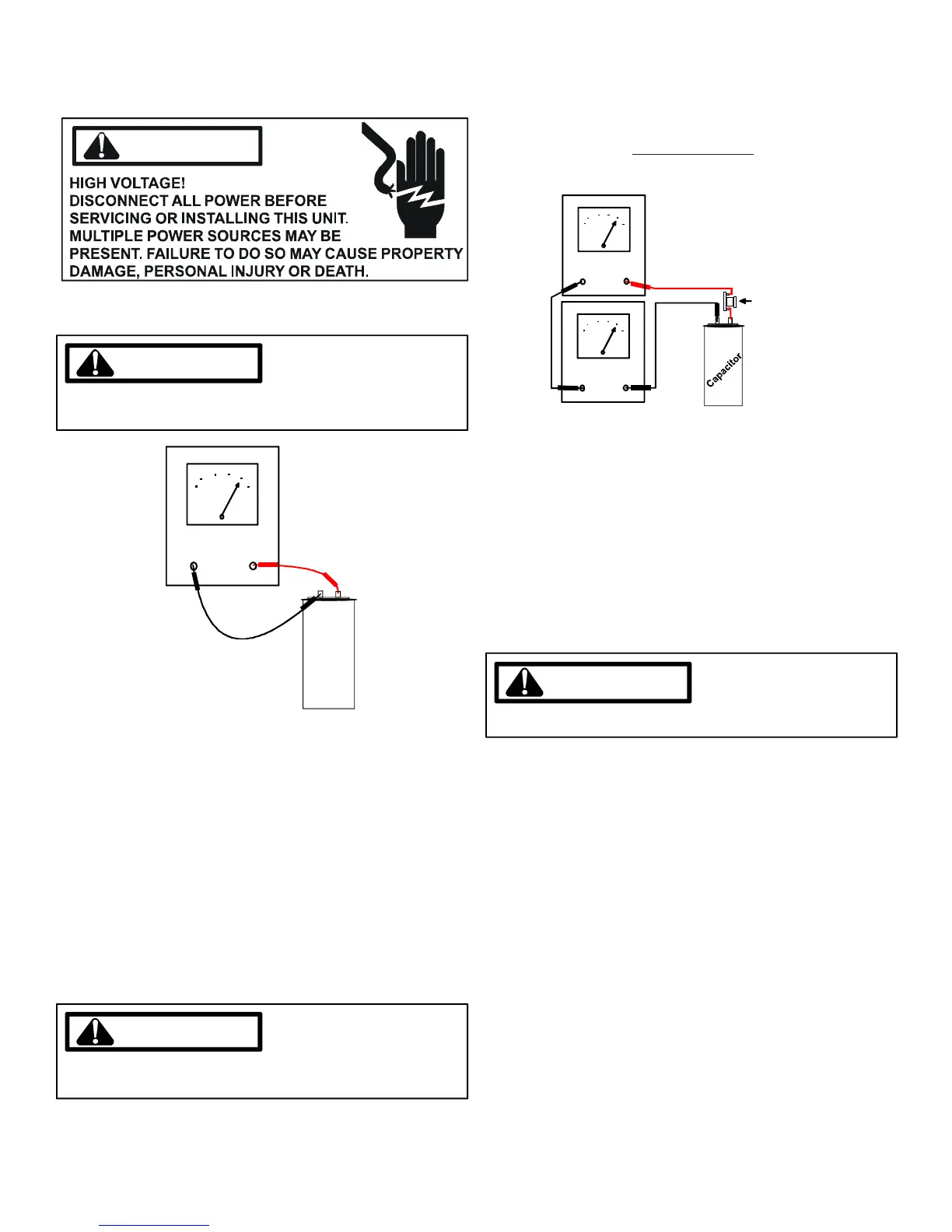

S-15A RESISTANCE CHECK

WARNING

1. Discharge capacitor and remove wire leads.

WARNING

DISCHARGE CAPACITOR THROUGH A 20 TO 30 OHM

RESISTOR BEFORE HANDLING.

Cap

a

cito

r

Volt / Ohm

Meter

TESTING CAPACITOR RESISTANCE

2. Set an ohmmeter on its highest ohm scale and connect

the leads to the capacitor -

A. Good Condition - indicator swings to zero and slowly

returns to infinity. (Start capacitor will bleed resistor will

not return to infinity. It will still read the resistance of the

resistor).

B. Shorted - indicator swings to zero and stops there -

replace.

C. Open - no reading - replace. (Start capacitor would read

resistor resistance).

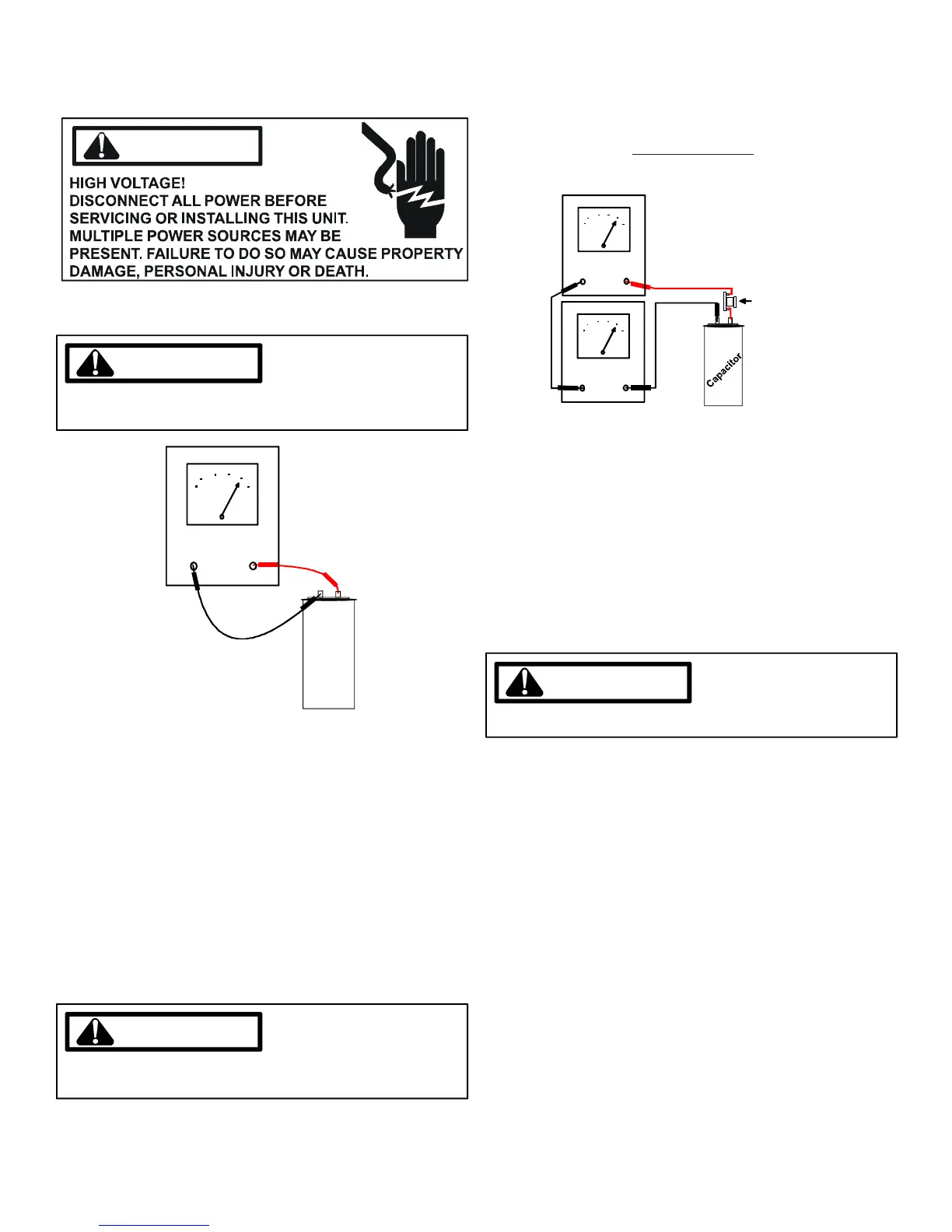

S-15B CAPACITANCE CHECK

WARNING

DISCHARGE CAPACITOR THROUGH A 20 TO 30 OHM

RESISTOR BEFORE HANDLING.

Using a hookup as shown below, take the amperage and volt-

age readings and use them in the formula:

Capacitance (MFD) =

2650 X Amperage

Voltage

15 AMP FUSE

Volt / Ohm

Meter

AMMETER

TESTING CAPACITANCE

S-16 CHECKING MOTORS

S-16A CHECKING FAN AND BLOWER MOTOR

WINDINGS (PSC MOTORS)

The auto reset fan motor overload is designed to protect the

motor against high temperature and high amperage conditions

by breaking the common circuit within the motor, similar to the

compressor internal overload. However, heat generated within

the motor is faster to dissipate than the compressor, allow at

least 45 minutes for the overload to reset, then retest.

WARNING

DISCONNECT POWER SUPPLY BEFORE SERVICING.

1. Remove the motor leads from its respective connection

points and capacitor (if applicable).

2. Check the continuity between each of the motor leads.

3. Touch one probe of the ohmmeter to an unpainted end of

the motor frame (ground) and the other probe in turn to

each lead.

If the windings do not test continuous or a reading is obtained

from any lead to ground, replace the motor.

S-16D CHECKING GE X13

TM

MOTORS

The GE X13

TM

Motor is a one piece, fully encapsulated, 3 phase

brushless DC (single phase AC input) motor with ball bearing

construction. Unlike the ECM 2.3/2.5 motors, the GE X13

TM

features an integral control module.

Note: The GE TECMate will not currently operate the GE X13

TM

motor.

1. Using a voltmeter, check for 230 volts to the motor connec-

tions L and N. If 230 volts is present, proceed to step 2. If

230 volts is not present, check the line voltage circuit to

the motor.

Loading...

Loading...