SERVICING

35

WARNING

SCROLL COMPRESSORS

DO NOT FRONT SEAT THE SERVICE VALVE(S) WITH

THE COMPRESSOR OPERATING IN AN ATTEMPT TO

SAVE REFRIGERANT. WITH THE SUCTION LINE OF

THE COMPRESSOR CLOSED OR SEVERLY RESTRICT-

ED, THE SCROLL COMPRESSOR WILL DRAW A DEEP

VACUUM VERY QUICKLY. THIS VACUUM CAN CAUSE

INTERNAL ARCING OF THE FUSITE RESULTING IN A

DAMAGED OR FAILED COMPRESSOR.

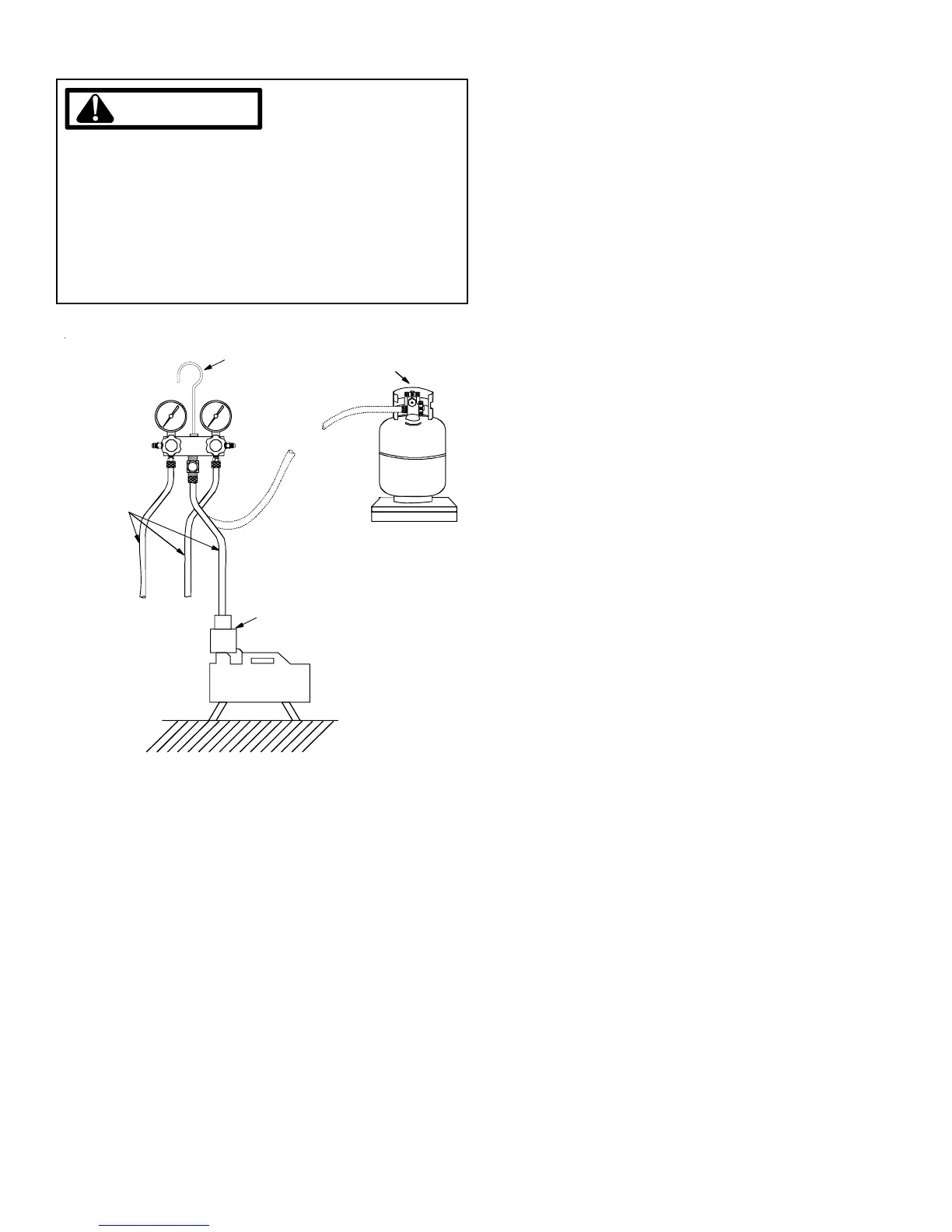

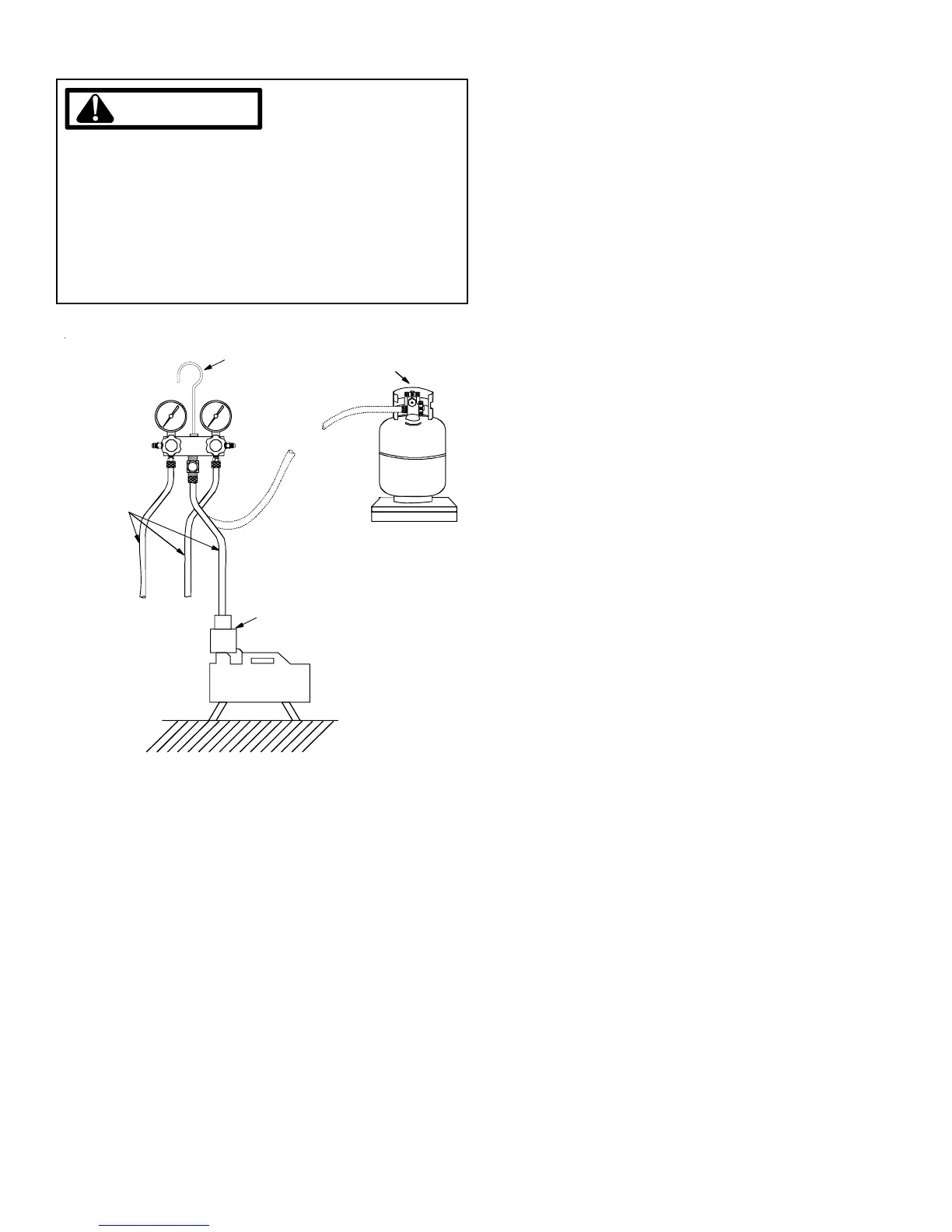

LOW SIDE

GAUGE

AND VALVE

HIGH SIDE

GAUGE

AND VALVE

TO

UNIT SERVICE

VALVE PORTS

VACUUM PUMP

VACUUM PUMP

ADAPTER

800 PSI

RATED

HOSES

CHARGING

CYLINDER

AND SCALE

{

R-22

MANIFOLD

1. Connect the vacuum pump, vacuum tight manifold set with

high vacuum hoses, thermocouple vacuum gauge and charg-

ing cylinder as shown.

2. If the service dill valves are to be used for evacuation, it is

recommended that a core remover be used to lift the core

for greater efficiency.

3. Start the vacuum pump and open the shut off valve to the

high vacuum gauge manifold only. After the compound

gauge (low side) has dropped to approximately 29 inches

of vacuum, open the valve to the vacuum thermocouple

gauge. See that the vacuum pump will blank-off to a maxi-

mum of 25 microns. A high vacuum pump can only pro-

duce a good vacuum if its oil is non-contaminated.

4. If the vacuum pump is working properly, close the valve to

the vacuum thermocouple gauge and open the high and

low side valves to the high vacuum manifold set. With the

valve on the charging cylinder closed, open the manifold

valve to the cylinder.

5. Evacuate the system to at least 29 inches gauge before

opening valve to thermocouple vacuum gauge.

6. Continue to evacuate to a minimum of 250 microns. Close

valve to vacuum pump and watch rate of rise. If vacuum

does not rise above 1500 microns in three to five minutes,

system can be considered properly evacuated.

7. If thermocouple vacuum gauge continues to rise and levels

off at about 5000 microns, moisture and non-condensables

are still present. If gauge continues to rise a leak is present.

Repair and re-evacuate.

8. Close valve to thermocouple vacuum gauge and vacuum

pump. Shut off pump and prepare to charge.

S-103 CHARGING

Charge the system with the exact amount of refrigerant.

Refer to the specification section or check the unit nameplates

for the correct refrigerant charge.

After completing airflow measurements and adjustments, the

unit’s refrigerant charge must be checked. The unit comes

factory charged, but this charge is based on 400 CFM per ton

at minimum ESP per ARI test conditions (generally between

.15 - .25 ESP). When air quantity or ESP is different than

above, charge must be adjusted to the proper amount.

All package units are charged to the superheat method at the

compressor suction line (these are fixed orifice devices).

For charging in the warmer months, 10

0

F superheat at the com-

pressor is required at conditions: 95

0

F outdoor ambient (dry

bulb temperature), 80

0

F dry bulb / 67

0

F wet bulb indoor ambi-

ent, approximately 50% humidity. This superheat varies when

conditions vary from the conditions described.

A superheat charge chart is available for other operating condi-

tions. Use it to provide the correct superheat at the conditions

the unit is being charged at.

After superheat is adjusted it is recommended to check unit

sub-cooling at the condenser coil liquid line out. In most oper-

ating conditions 10 - 15

0

F of sub-cooling is adequate.

An inaccurately charged system will cause future problems.

1. Using a charging scale, allow liquid refrigerant only to enter

the high side.

2. After the system will take all it will take, close the valve on

the high side of the charging manifold.

3. Start the system and charge the balance of the refrigerant

through the low side. DO NOT charge in a liquid form.

4. With the system still running, close the valve on the charg-

ing manifold. At this time, you may still have some liquid

refrigerant in the charging manifold and will definitely have

liquid in the liquid hose. Reseat the liquid line core. Slowly

open the high side manifold valve and transfer the liquid

refrigerant from the liquid line hose and charging manifold

into the suction service valve port. CAREFUL: Watch so

that liquid refrigerant does not enter the compressor.

Loading...

Loading...