- 8 - B.6.20.44-B

F22.060.02, issued on 01.98

The individual parts of the suction system are designed to withstand an excess pressure of

12 bar (- Suitable for suction heights of up to 8.5 m).

The suction hose and the suction sieve are resistant to the usual solvents in the surface

coating and are silicone-free.

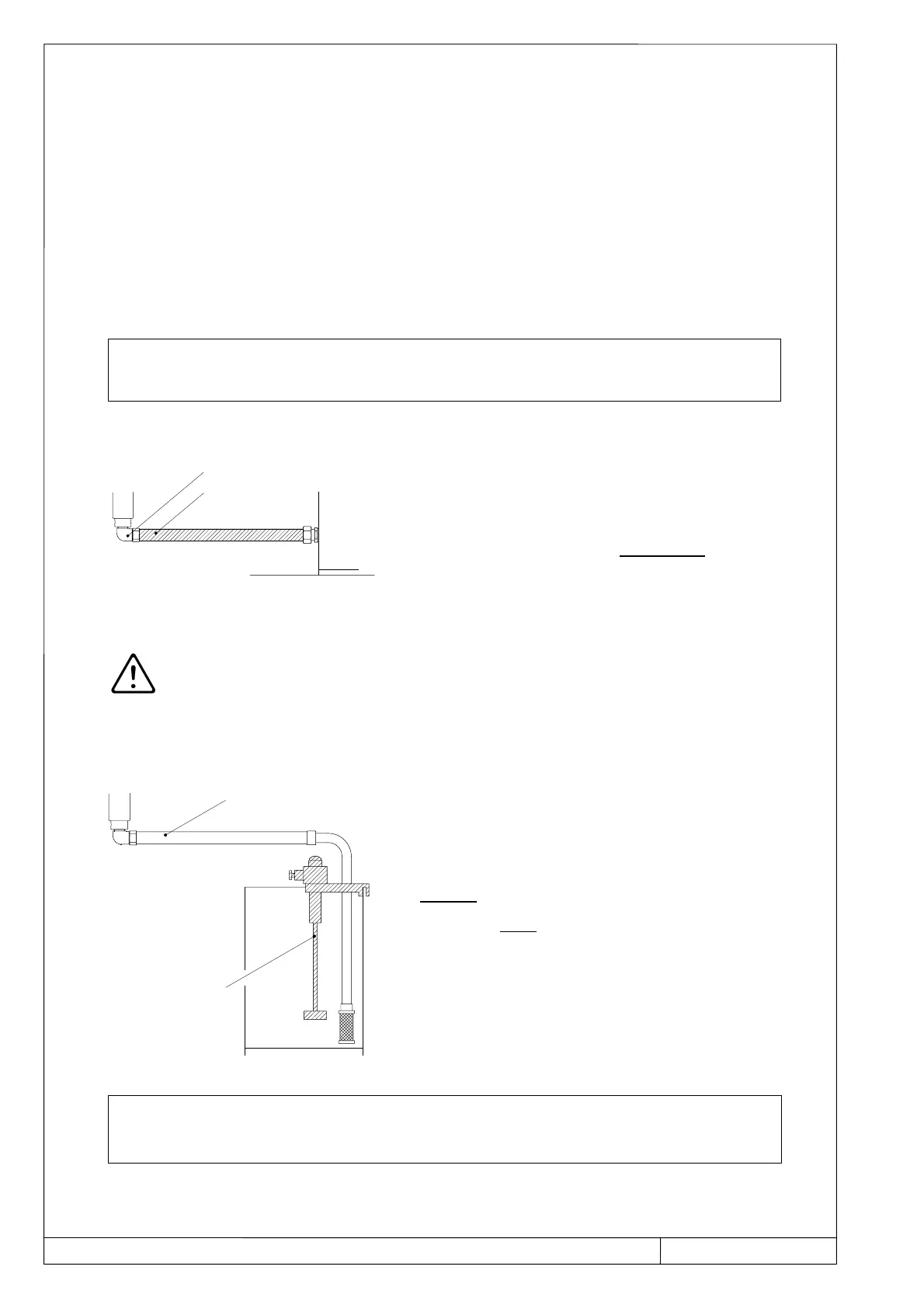

Minimum rated diameter 19

Fluid temperature 10 °C to 85 °C

Mesh size of screen 1.8

In case of a fixed installation the connection between

reciprocating pump and fluid container must be flexible

(to avoid rupture caused by vibration).

The ratings for this connecting suction line must

correspond with those of the suction equipment.

The admission pressure (pressure in a supply system, e.g. in a circuit) acting on the

reciprocating pump and the suction line, must not exceed 10 bar.

When a threaded tube is used in the suction assembly, the manufacturer’s directions for

installation of the screwed connection apply.

The viscosity of thixotropic fluids is reduced by stirring;

this improves e.g. the suction behaviour of the

reciprocating pump.

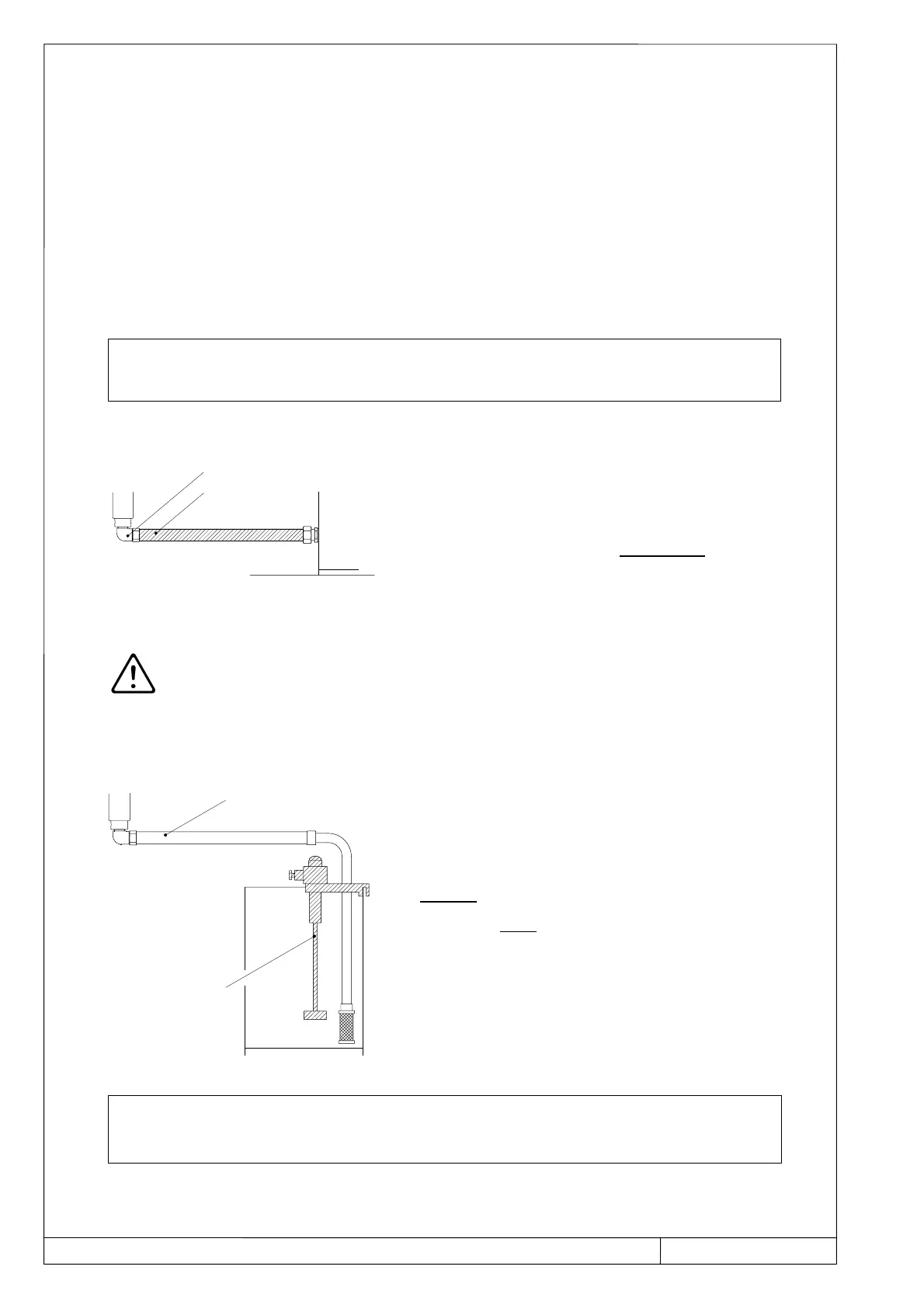

The agitator is clamped to the suction equipment. The

clamp (holder) must be fastened to the rim of the fluid

container. This ensures correct positioning of the

propeller of the agitator relative to the wall and base of

the container as well as to the suction tube, and prevents

the parts from touching.

All metal parts in contact with the suction area material are made of austenitic

stainless steel. (suitable for use with water lacquer).

All immersed parts of the agitator (spindle and propeller) are made from austenitic

stainless steel (suitable for water-based paints).

Connector 1

Suction pipe

Suction

Agitator

Loading...

Loading...