- 20 - B.6.20.44-B

F22.060.02, issued on 01.98

Screw off the union nut and remove the screen housing.

Introduce the screen insert into the housing via the support spring and fasten the housing again.

FLUSH THE RECIPROCATING PUMP

As every reciprocating pump is tested in the works after assembly using an anti-corrosion liquid it is

necessary to thoroughly flush out the rest of this liquid (and any other contaminants which have

entered during installation) with detergent (flushing agent).

Then the detergent should be removed from the system as much as possible (not from the coupling

housing). This is done by air suction.

– Air inlet pressure (manometer to the air motor) < 1bar.

START UP OF APPLIANCE / SYSTEM

Because the reciprocating pump works automatically with back pressure, it can only be

commissioned (i.e. fluid be conveyed) when fluid is discharged from the pressure system, e.g. by

using the spraying equipment.

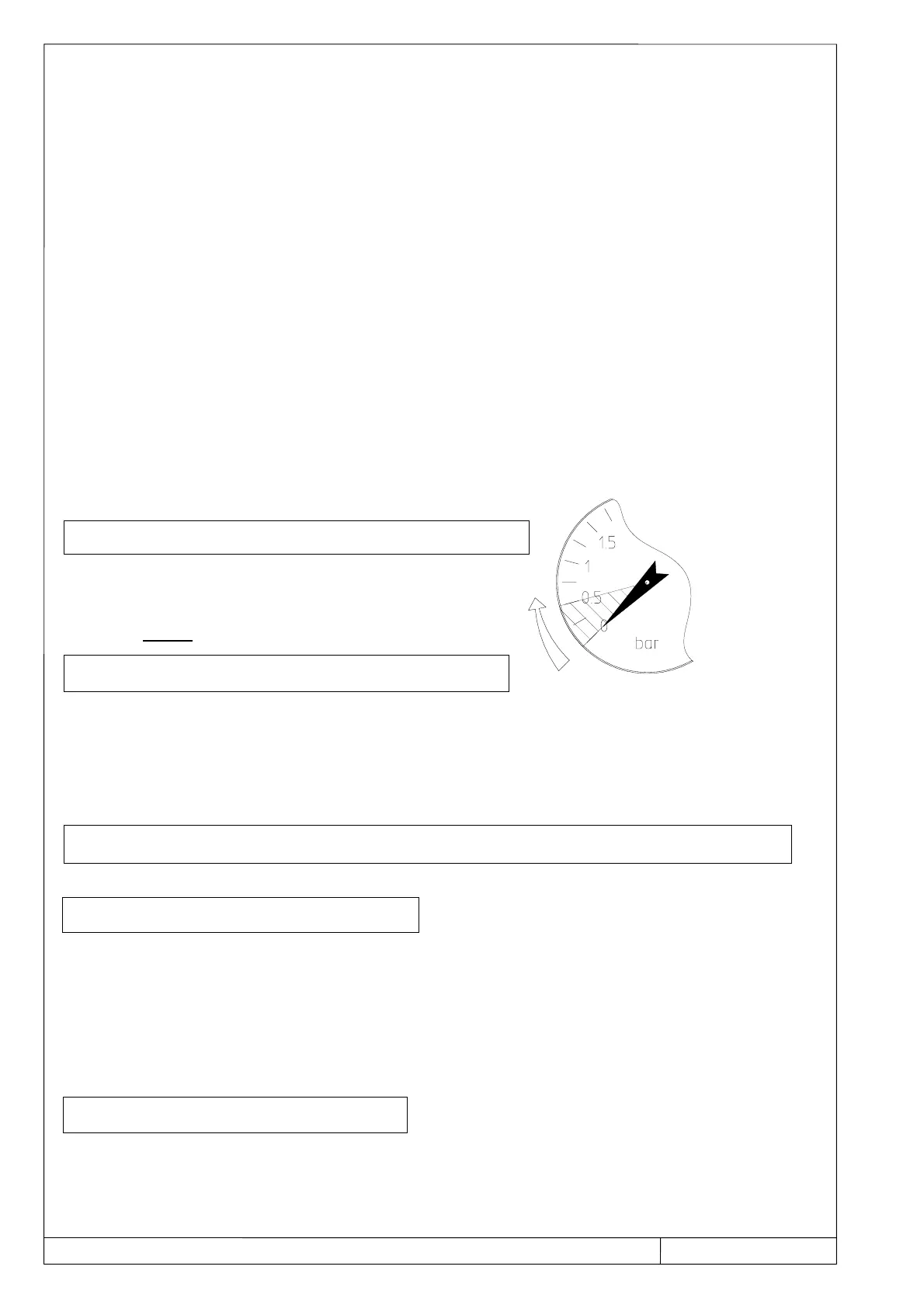

In order to guarantee fault-free starting of the

reciprocating pump, the pressure control valve

should be rapidly opened to 0.5 bar.

AERATING (BLEEDING) OF APPLIANCE/PLANT

The air, which has entered the pump and the system after flushing must be thoroughly removed.

PREPARING FOR SPRAYING

ADJUST (PLACE) THE STUFFING

Raise the material excess pressure slowly to the maximum value. Operate the reciprocating pump

at this pressure for a short time. Then set the required operating pressure.

- Spra

in

e

uipment without nozzle, dischar

e operated

- Quickly set 0.5 bar air pressure, then regulate normally

- Lock spray equipment, install nozzle.

- Appliance /system is ready for operation.

- Operate the reciprocating pump with < 20 bar fluid pressure until no more air is pumped.

Loading...

Loading...