- 22 - B.6.20.44-B

F22.060.02, issued on 01.98

OPERATION

The reciprocating pumps run automatically, i.e. during operational shutdown (no fluid drawn from

fluid pressure system) no fluid is pumped. If there is a slight leakage, however, pumping will start.

It is therefore recommended that the pump be disconnected from the air supply overnight or at the

weekend and, if possible, material pressure be reduced by withdrawal (after the air is disconnected.)

This can be achieved by using a spray device for example.

It is also recommended to drain the detergent before an

operating pause (over night) and to fill up again when work

starts again (on the next day) provided that it is not yet

contaminated.

In order to drain the detergent, turn the detergent filling

connector to the left (max 180°).

Before filling, turn back to the starting position.

Do not tighten with a tool (lever)

- Risk of breaking

Before long-term shutdown, e.g. company holidays, pumps carrying paint should be flushed.

In order to avoid the hardening of paint residue the detergent should remain in the pump during

shutdown.

We recommend using alkyl sulphon acidic ester, "ASE" phenol, as the flushing agent.

Consult the material supplier concerning the compatibility of the detergent.

Do not use nitro thinners or solvents as flushing agents.

MAINTENANCE AND INSPECTION, REPAIR

MAINTENANCE AND INSPECTION

MERKUR 2000 RECIPROCATING PUMPS REQUIRE LITTLE MAINTENANCE

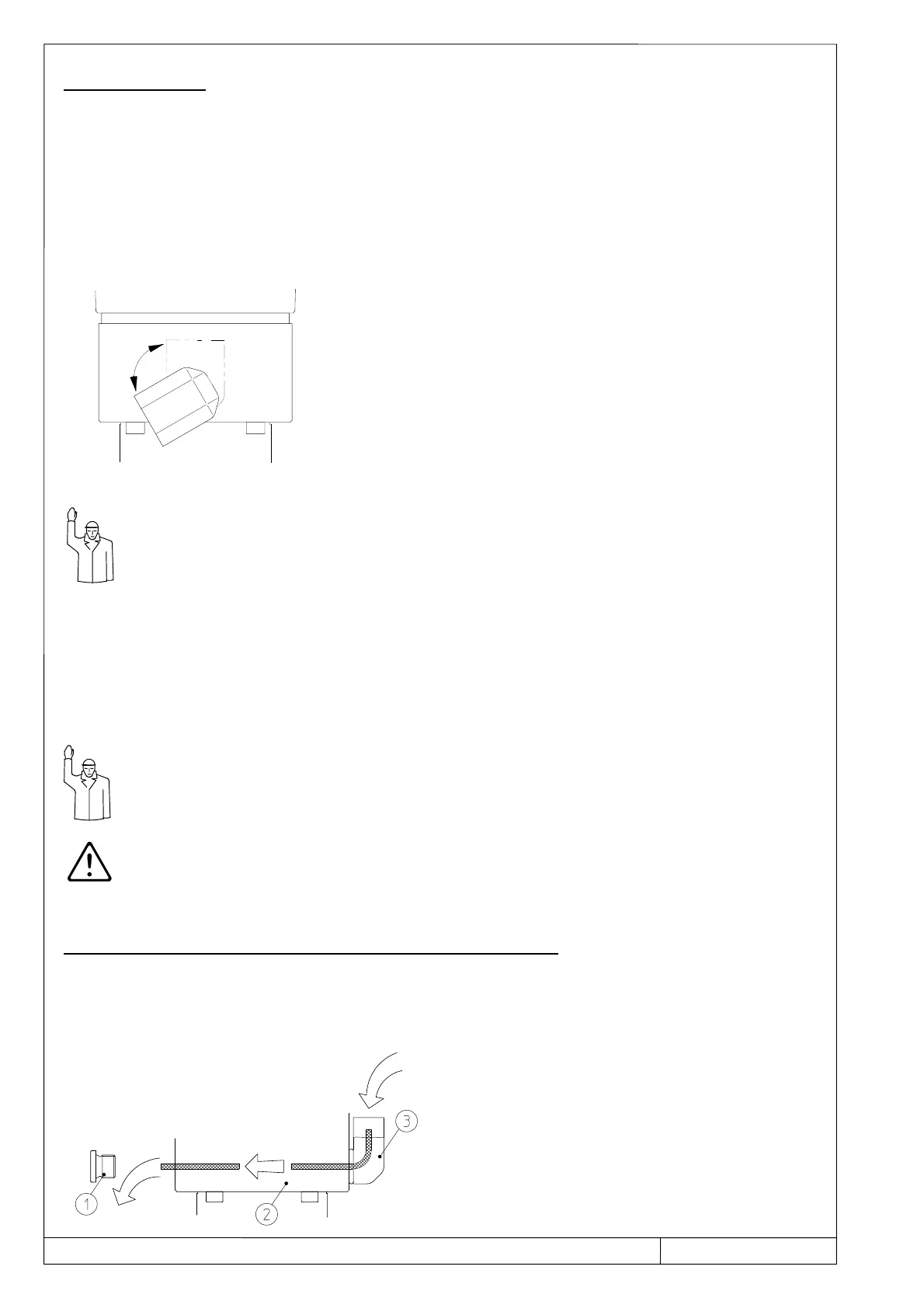

The detergent should be replaced after

coloration or 1x month

- Drain using the fixing plug 1

- Flush the housing 2 with detergent

- Fill the filling connector up to the middle

Loading...

Loading...