-

- B.6.20.44-B

F22.060.03, issued on 01.98

If there is no automatic water drainage in the air pressure supply to the pressure regulation

valve, then drain the condensed water every day from the pressure container, filter or filter

regulator.

When using anti-freeze (when operating at around 10 °C), replenish it after use.

Regularly check the dirt trap on the suction side.

- The cleaning interval depends on the fluid and must be determined by the operator.

The safety valve of the reciprocating pump should be checked for proper operation once a year.

For this, the max. permissible operating overpressure must be slightly exceeded

(opening pressure up to 1.1 x max. permissible operating overpressure).

Regularly dismantle the screen PN 500

– The top part remains at the pump. Thoroughly clean all the other parts.

The cleaning interval depends on the coating substance or auxiliary agent and must be

determined by the operator.

The service life of the hose lines is adversely affected, and thus shortened, by surrounding

influences (oxygen in air, temperature, light, etc.), even if correctly.

It is recommended that they undergo regular visual checks and occasional checking of

performance.

As a precaution the hose lines should be replaced at intervals set by the operator (- after 2 to 3

years).

Never at any time dismantle a reciprocating pump which is under pressure.

Observe the reciprocating pump regularly every day while it is in operation.

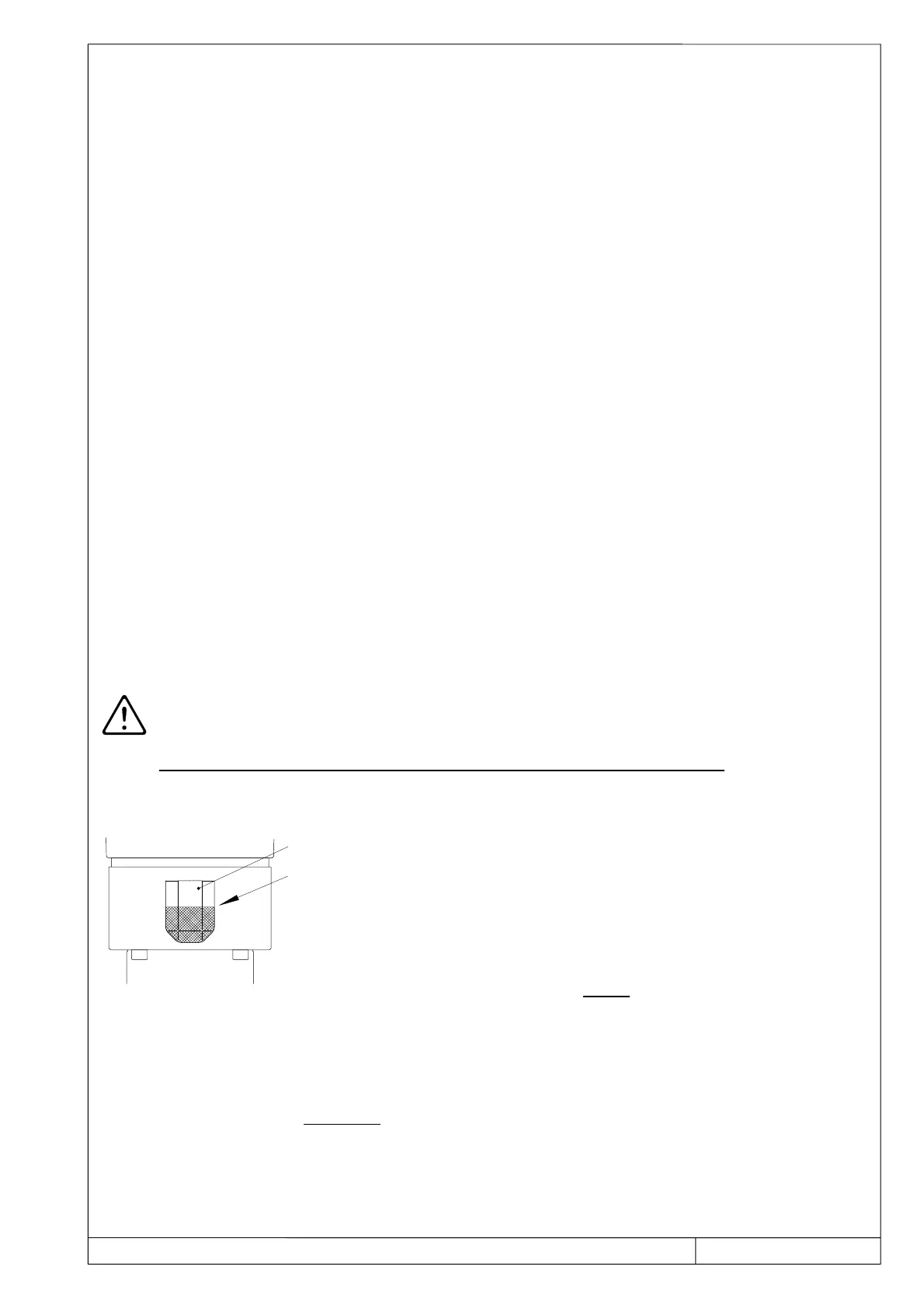

The lubricant in the coupling housing should be checked every

day.

The detergent level should be visible in the filling connector

and as much as possible in the middle.

If the detergent has visibly changed in color, it should be

replaced (see pages 19 and 22).

If the detergent level rises slowly when the reciprocating pump

is operating, this is a sign of progressive wear of the piston rod

stuffing (top). The reciprocating pump must now be checked

more frequently (several times a day)

If the detergent level rises noticeably when the pump is operating between the daily checks, this

means that the piston rod stuffing is so worn out that it must be replaced as quickly as possible.

- It is recommended to also replace the piston stuffing (below) during the course of this work.

Filling

connector

Detergent

level

Loading...

Loading...