Pressure

T

ransducer

WARNING

INJECTION

HAZARD

T

o reduce the risk of serious injury

,

whenever you are instructed to relieve

pressure, follow the

Pressure Relief

Procedure

on page 10.

NOTE:

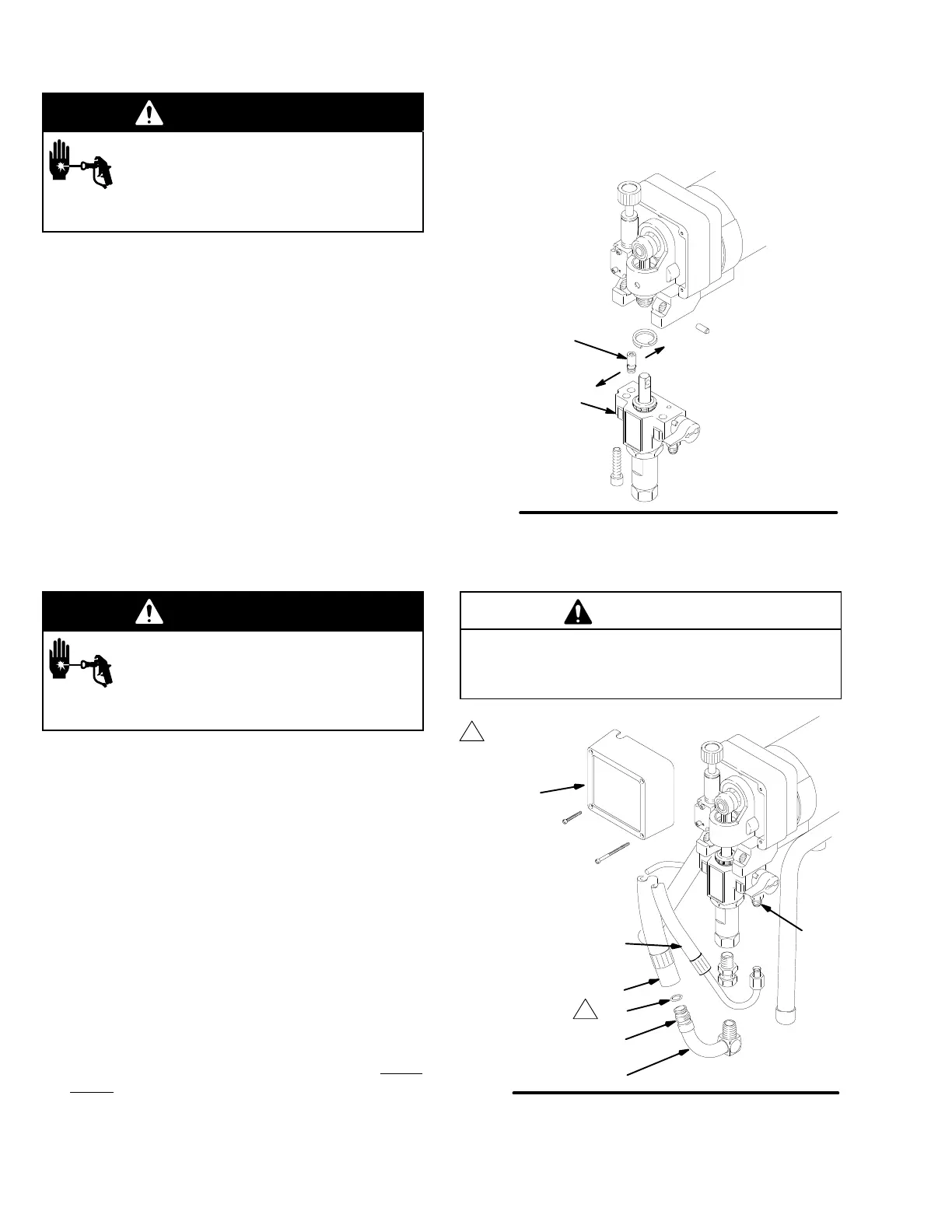

See Fig. 25 for this procedure.

1.

Remove the displacement pump. See page 22.

2.

Use a pull–twist motion to remove the transducer

(29) from the pump manifold (101).

3.

Clean paint residue from the hole in the manifold;

do not scratch the surface of the hole.

4.

Lightly apply oil to the o-ring of the new transducer

.

5.

Install the transducer in the pump manifold, while

guiding the o-ring and backup ring into place.

6.

Align the holes in the transducer as shown by the

arrows in Fig. 25.

7.

Install the displacement pump. See page 22.

Fig. 25

02817A

101

29

Suction

Hose

WARNING

INJECTION

HAZARD

T

o reduce the risk of serious injury

,

whenever you are instructed to relieve

pressure, follow the

Pressure Relief

Procedure

on page 10.

1.

Remove the drain hose (33) from the clip. Remove

the front cover (13).

2.

Pull upward on the hose (32) while unscrewing it

from the inlet tube (38). The hose coupling (A)

threads will engage and the hose will separate

from the tube.

3.

Replace the o–ring (27) if it is worn or damaged.

4.

Lubricate the o–ring (27) and the inlet tube (38)

threads with light grease.

5. Align the suction hose coupling with the threads of

the

inlet tube (38). T

ighten the hose onto

the tube at

least 4 turns to ensure that the threads have disen-

gaged

and can function as a swivel joint.

CAUTION

Misalignment or cross-threading will damage the

parts and/or create shavings which can cause the

o–ring (27) to leak.

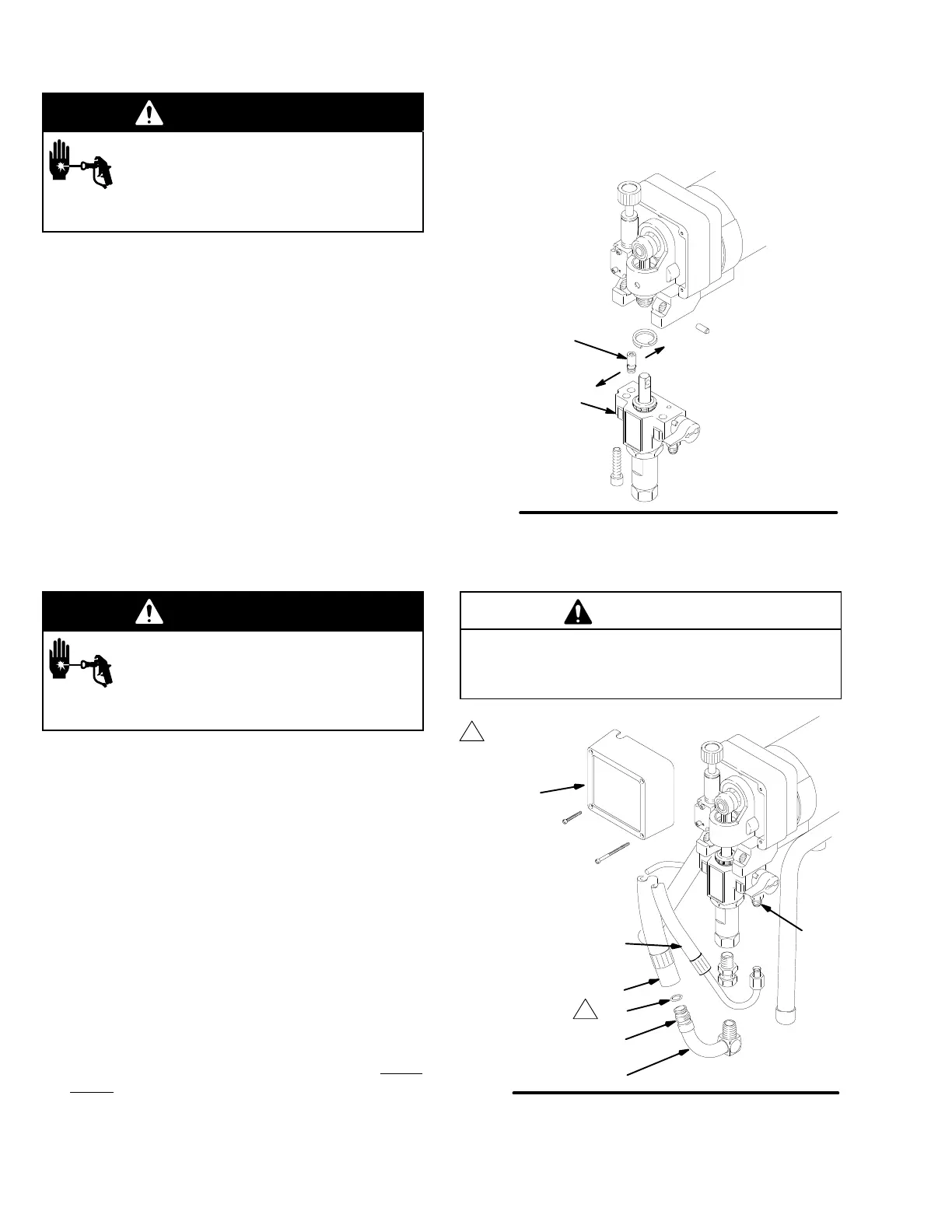

06978

33

32

36

38

27

13

A

Fig. 26

1

Lubricate

1

Note:

Filter

not shown

Loading...

Loading...