16 308155

Service

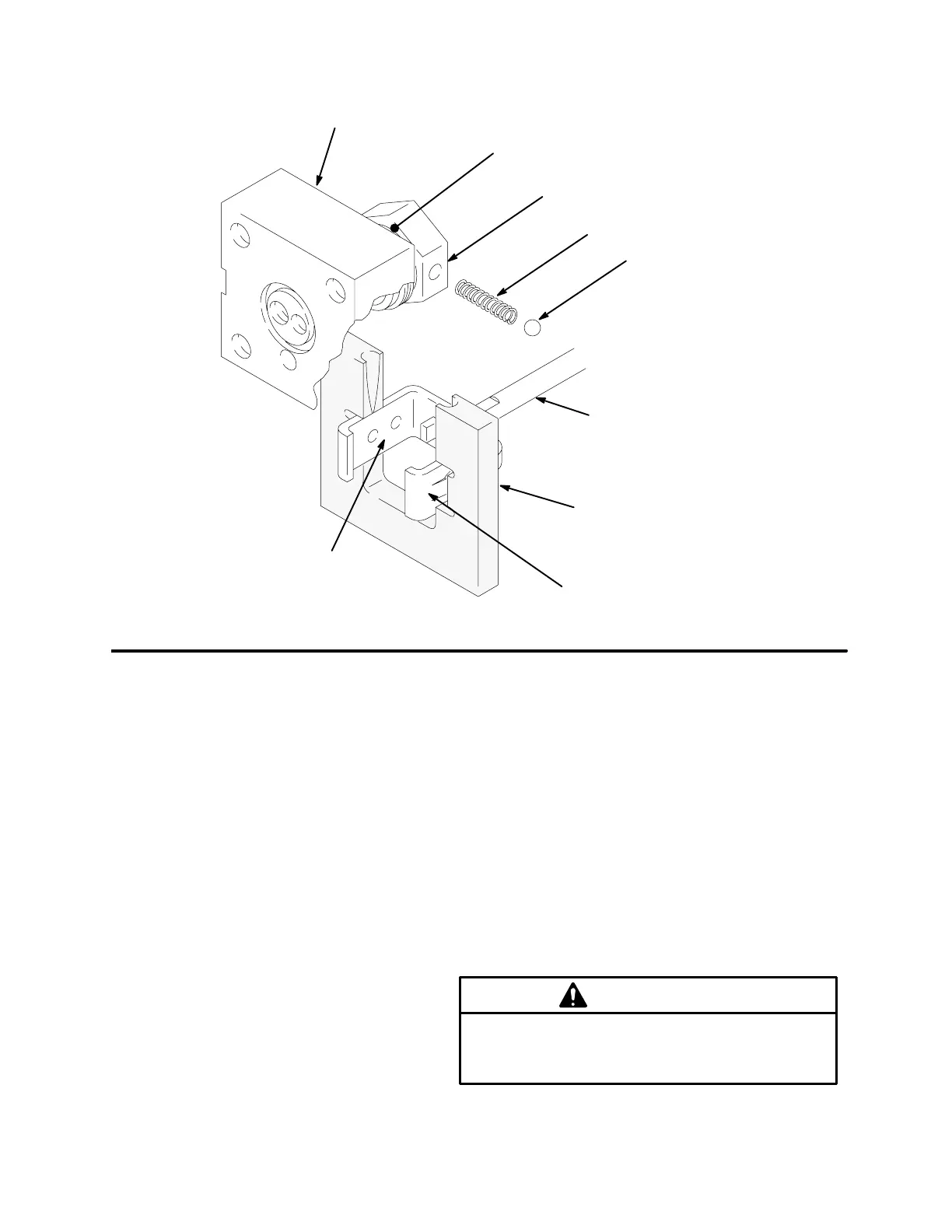

Fig. 10

31

ASSEMBLY B

26

6

7

9

29

12

ASSEMBLY A

C

D

06148

13. Lay Assembly A and Assembly B on the

workbench.

14. Slide Assembly B into the center of the tool (D),

Part No. 189305. Align the upper detent holes (C)

of the guide yoke (9) with the center line of the tool

(D). See Fig. 10.

15. Insert the spring (6) and one ball (7) into the valve

stop (26) of Assembly A. Tilt the valve stop, and

start guiding it into the tool (D), making sure the

ball is sliding into the rounded slot in the tool (D).

Place the other ball at the other end of the spring,

and push it in with your thumb while rotating the

valve stop (26) until the spring is horizontal and the

balls are in place. Continue holding this assembly

together. See Fig. 10.

16. Slide the valve stop assembly down onto the tool.

Make sure the balls (7) snap into the upper set of

holes (C) in the guide yoke (9), and the curved

ends of the guide clamp have engaged the valve

sleeve (29) groove. See Fig. 10. Slide the tool (D)

back over the rod (12) to remove it.

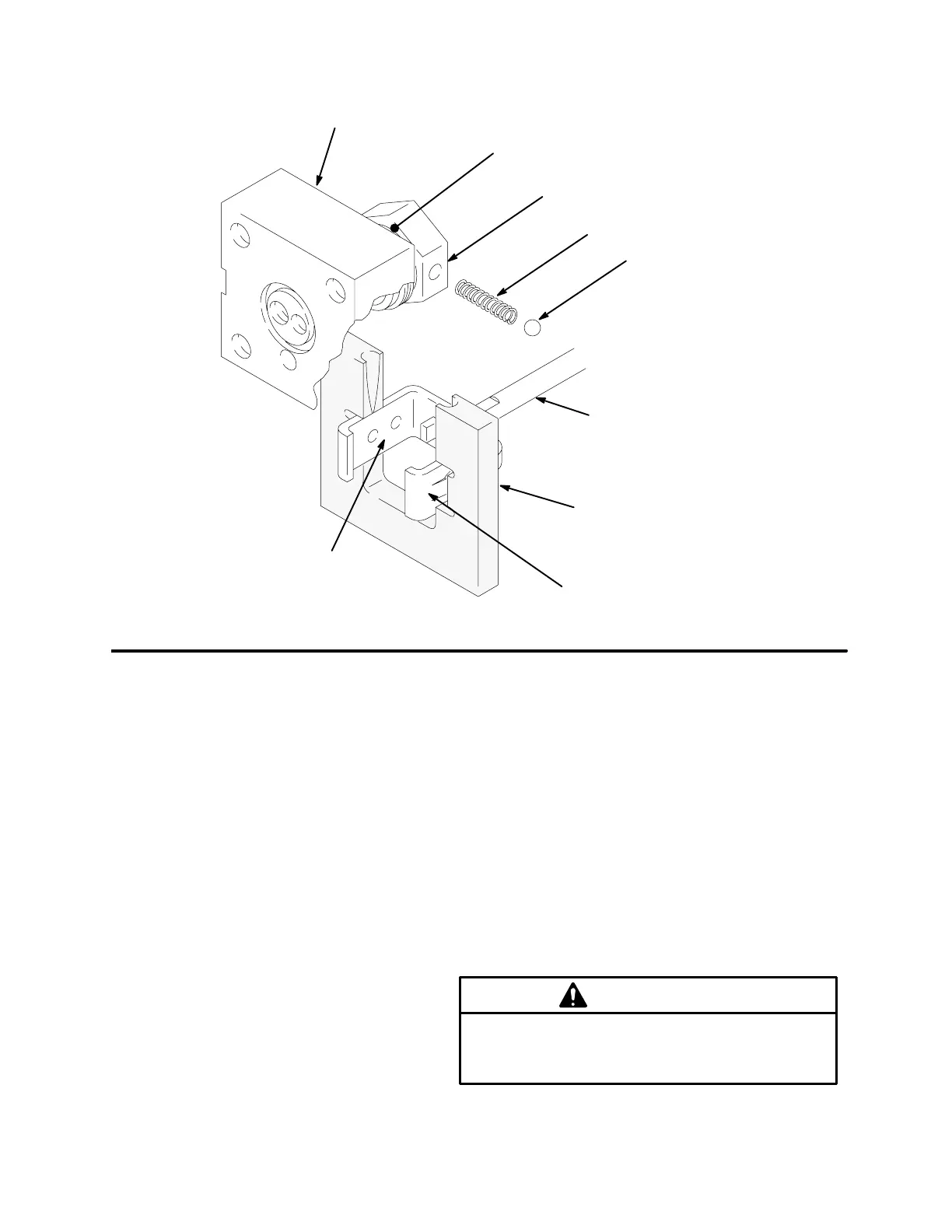

In steps 18 through 26, see Fig. 11.

17. Place the adapter (43) in a vise, and install the

seals as described on page 12. Install the cylinder

cap (32).

18. If the tie rods (38) were removed, reinstall them

with the short threaded end up. The other end

should be screwed about 9/16” into the bottom

cylinder cap (32).

19. Install the o-ring (49*) in the deep lower groove of

the piston (22), and install the seal (23*) over the

o-ring. Install the piston bearing (24*) around the

upper groove of the piston. Holding the piston

bearing in place to avoid damage, slide the

cylinder over the piston, and press it down.

CAUTION

When you insert the piston into the cylinder, care-

fully guide the piston seal (23*) and bearing (24*)

to prevent damaging them.

Loading...

Loading...