PressureReliefProcedure

Pressure Pressure

Pressure

Relief Relief

Relief

Procedure Procedure

Procedure

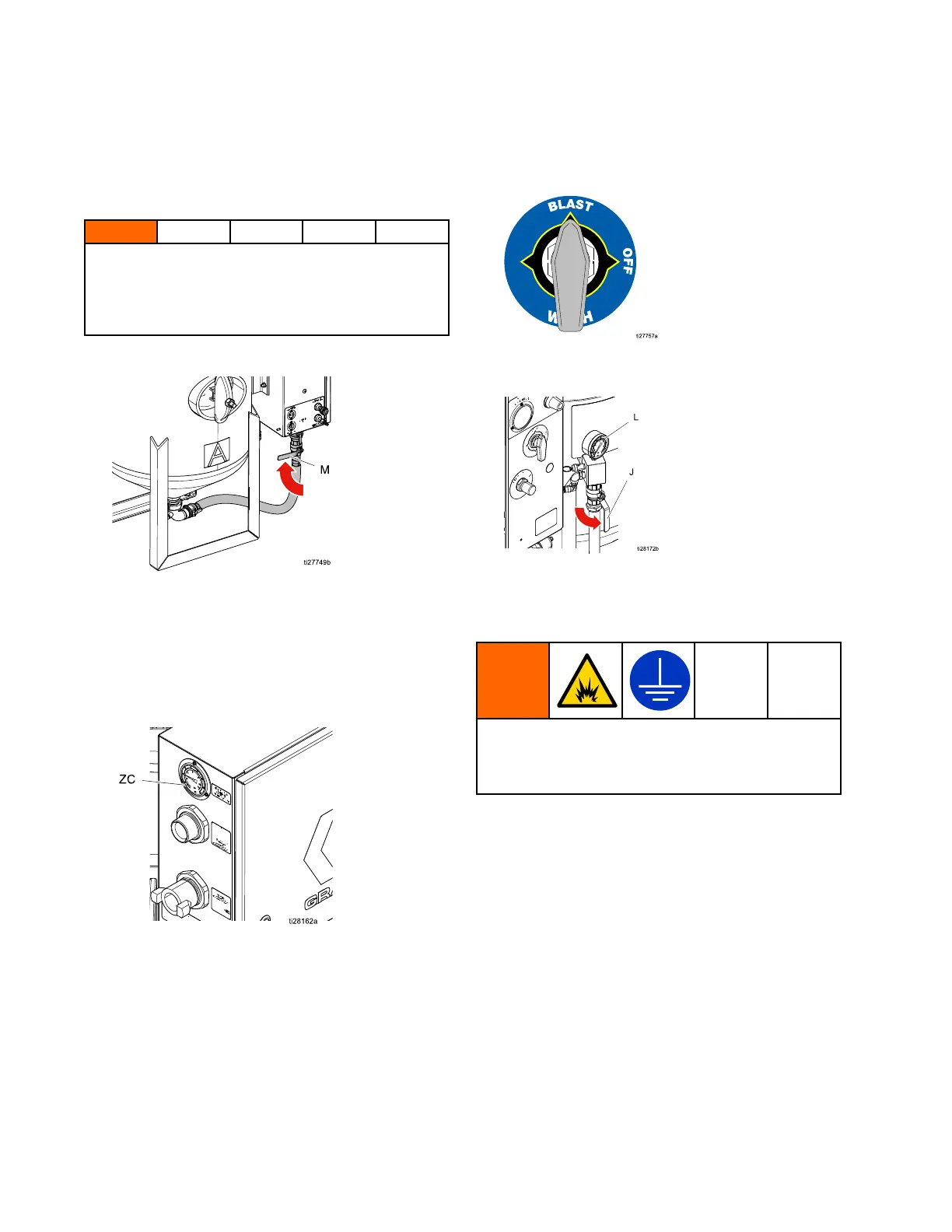

FollowthePressureReliefProcedure

wheneveryouseethissymbol.

Thisequipmentstayspressurizeduntilpressure

ismanuallyrelieved.Tohelppreventserious

injuryfrompressurizeduid,suchassplashing

uid,followthePressureReliefProcedurewhen

instructed.

1.Closetheabrasiveballvalve(M).

2.Closethecompressorsupplyairvalve,thenturn

thecompressoroff.

3.Engagetheblastcontrolswitch(B)torelieve

pressureinthesystem.

4.Verifythatthesupplypressuregauge(ZC)reads

0psi.Thendisconnecttheairinlethosefromthe

system.

5.Turntheselectorvalve(W)toBLAST.

6.Openthepotdumpvalve(J)untilthepot

pressuregauge(L)reads0psi.

Grounding Grounding

Grounding

(ATEX (ATEX

(ATEX

systems systems

systems

only) only)

only)

Theequipmentmustbegroundedtoreducethe

riskofstaticsparking.Staticsparkingcancause

fumestoigniteorexplode.Groundingprovidesan

escapewirefortheelectriccurrent.

Systems: Systems:

Systems:

Usesuppliedgroundwireandclamp

(237686).

Air Air

Air

and and

and

uid uid

uid

hoses: hoses:

hoses:

UseonlygenuineGraco

conductiveblasthoseswithamaximumof150ft(45

m)combinedblasthoselengthtoensuregrounding

continuity.Checktheelectricalresistanceoftheblast

hoses.Ifthetotalresistancetogroundexceeds29

megaohms,replacetheblasthoseimmediately.

Air Air

Air

compressor: compressor:

compressor:

followmanufacturer’s

recommendations.

10 3A3489E

Loading...

Loading...