Operation

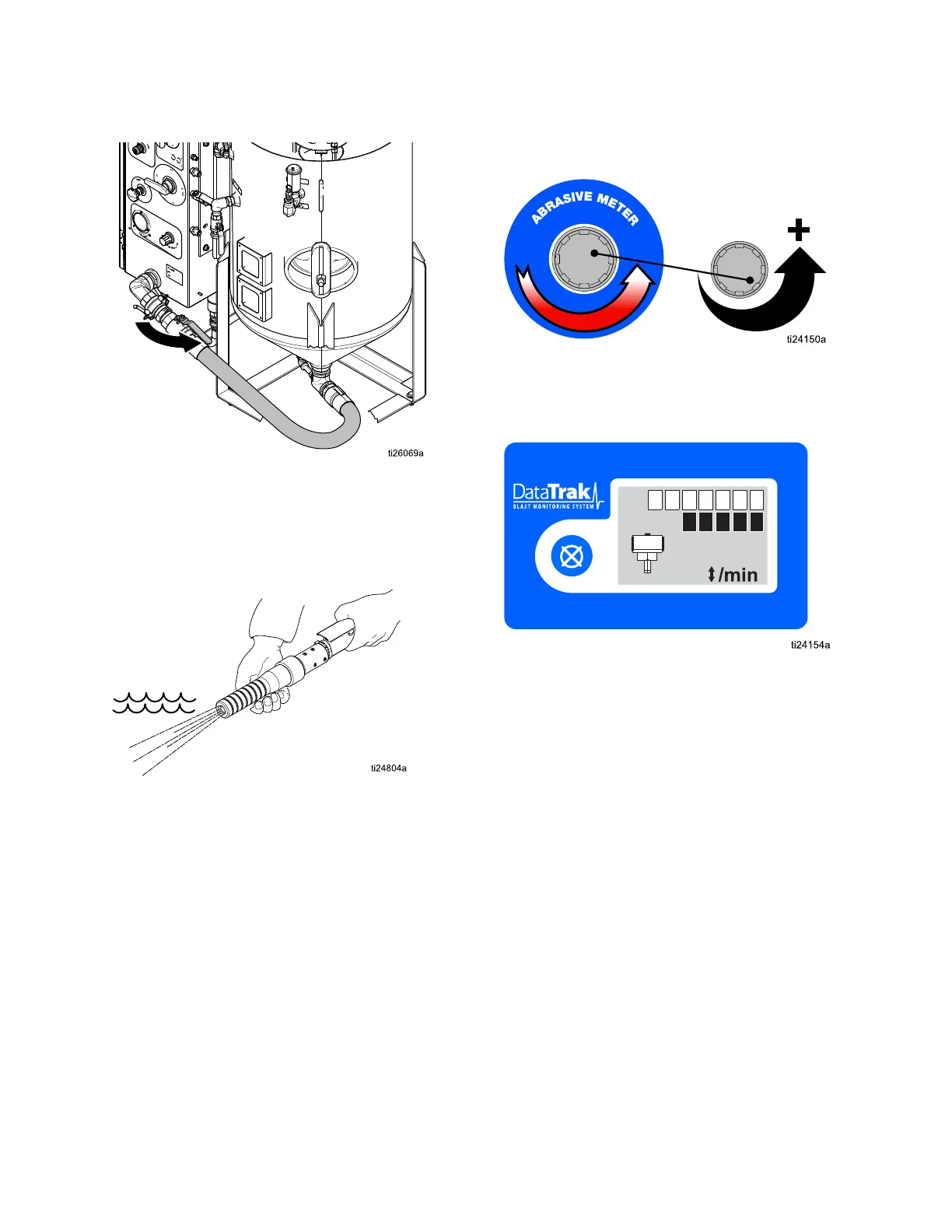

19.Opentheabrasiveballvalve.

NOTE: NOTE:

NOTE:

Makesurethepotpressurereturnstothe

initialsetting(itwillnotreturntotheinitialsetting

iftheabrasivemeteringvalveisclosed).

20.Engagetheblastcontrolswitchandbegin

blasting.

NOTE: NOTE:

NOTE:

Youmayhavetowait1–2minutesforthe

abrasivematerialtoreachthenozzle.

NOTE: NOTE:

NOTE:

Potpressureandblastpressureshould

equalizeduringblasting.Onlysetpotpressure

withtheabrasiveballvalveclosed.Neveradjust

potpressurewhileblasting.

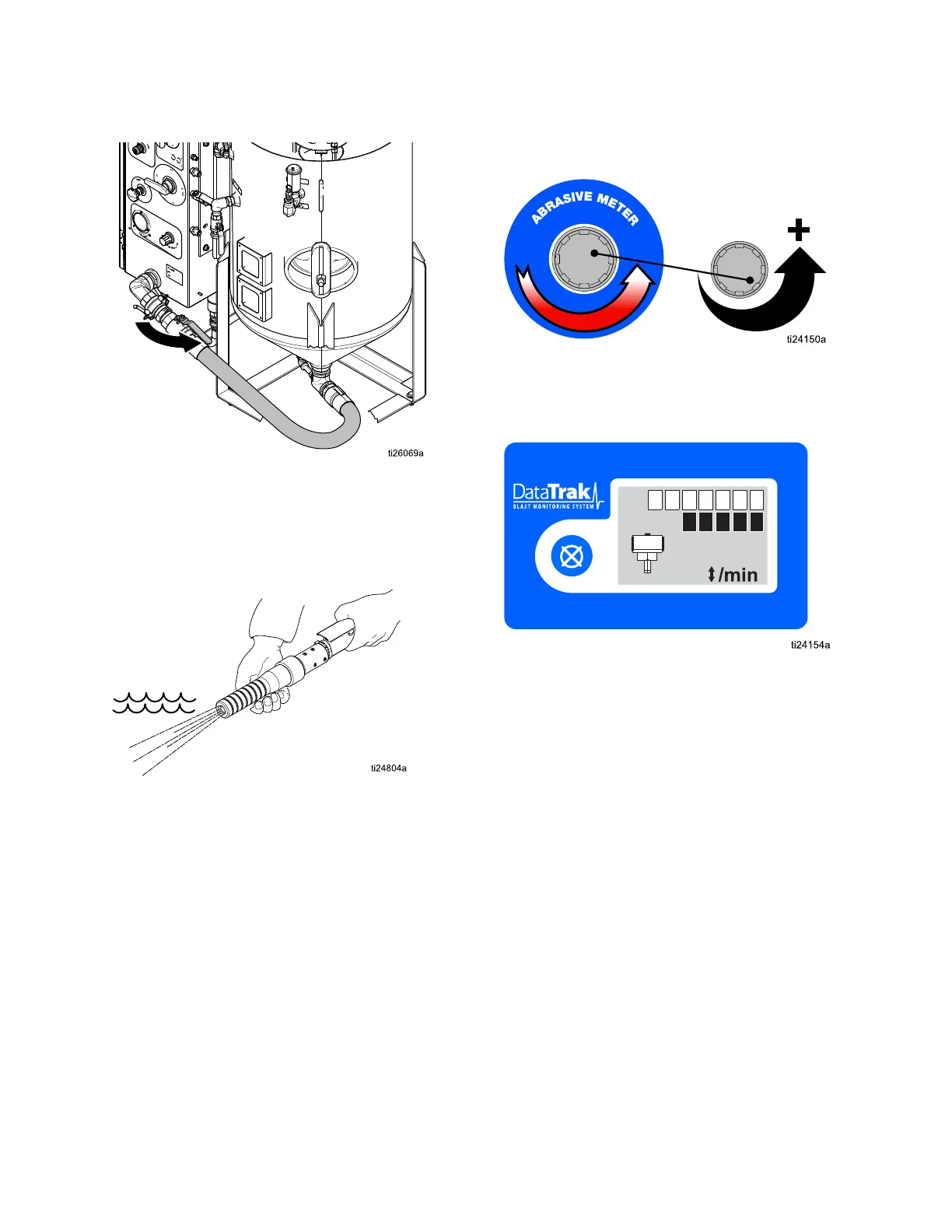

21.Slowlyadjusttheabrasivemeteringvalvewhile

theabrasiveisblastingfromthenozzle.Typical

adjustmentrangesfrom1/8to1/4turnopen.

NOTE: NOTE:

NOTE:

TheDataTrakcanbeusedtoassistin

settingthepumpcyclerate.Optimalabrasive

mediaconsumptiontypicallyoccurswiththe

cycleratesetat7–10cyclesperminute.

NOTE: NOTE:

NOTE:

Useapieceoftestmaterialsimilarto

whatyouwillbeblasting.

NOTE: NOTE:

NOTE:

Alwaysstartasgentlyaspossibleand

thenincreasetheblastforceasnecessaryto

cleanwithoutdoinganydamagetothesubstrate.

Whenproperlyset,thepumpshouldcycle7-10

timesperminute.Highproductionrateusers

mayneedtoincreasecyclerateabove10cycles

perminute.

NOTE: NOTE:

NOTE:

Closetheabrasiveballvalvewhenever

youstopblastingformorethan20-30minutes.

Thiswillhelptoextendtheservicelifeofthe

diaphragmvalve.

14

334666C

Loading...

Loading...