~~~~~~~~~~~~~~~~~~~~

&&..,*ns;.+.&/d

~~~~,sk.sA&,~~~~~~~,~~;~

D

I

S

p

LAC

EM

E

NT

p

U

M

p

~~~~~~~~~~~~~~~~~~~~~~~~~~

,X&*.,

"

.w

%d,>*>

.,,~~~.,~~,~~~~~~~~,~:~~~~,

WARNING

5.

Tighten the

nut

(211)

onto

the rod (224) to 19 ff-lb

(25 Nm). Use

two

wrenches

to

maintain the alignment

as mentioned

in

Step 3.

sleeve.

If

the sleeve is stuck, send the cylinder

to

your Graco distributor for removal. 6. Stack the throat packings into the top of the cylinder

(219). Install the packing nut (216) loosely.

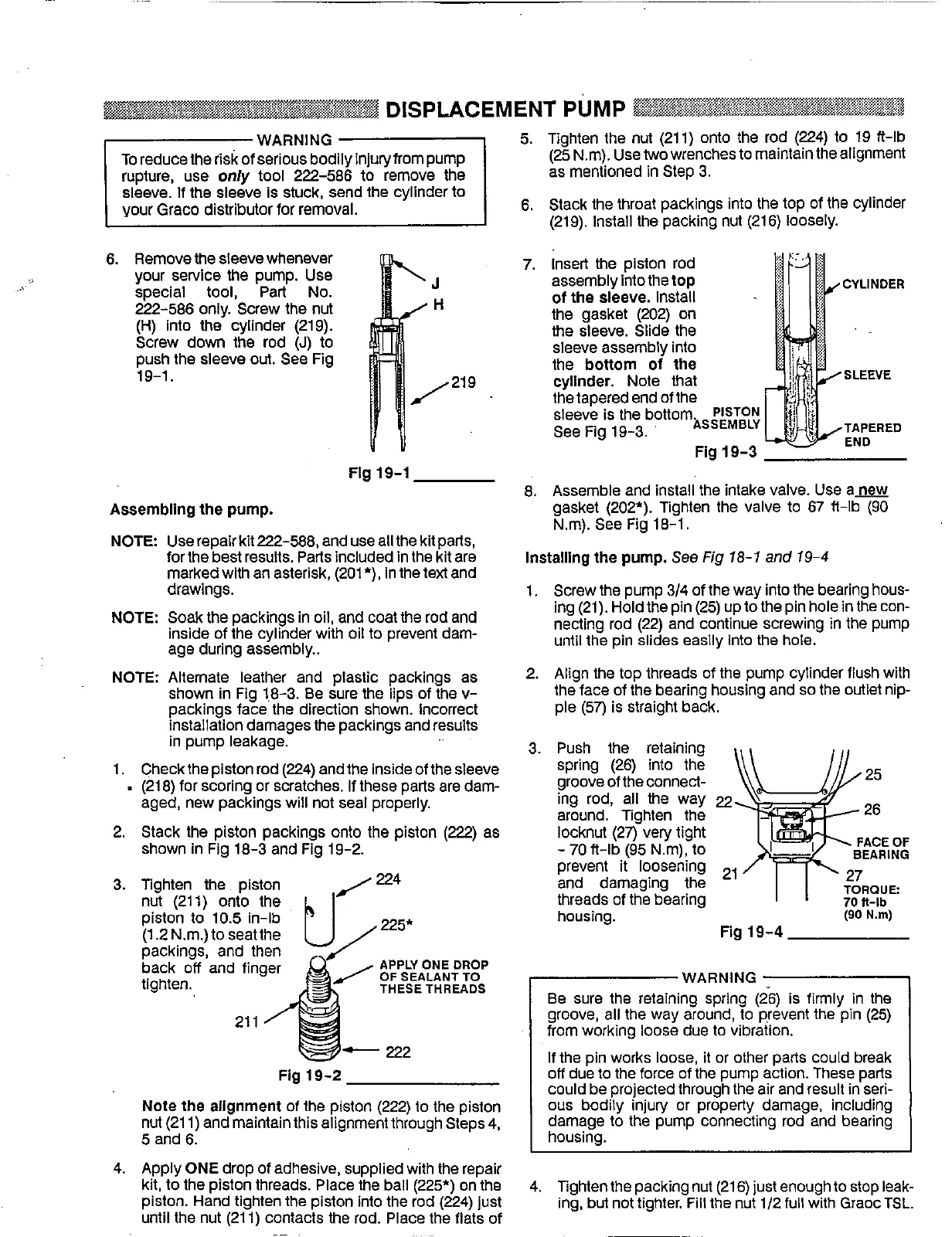

6.

Remove the sleevewhenever

your service the pump. Use

special

tool,

Part No.

222-586 only. Screw the

nut

(H)

Into

the cylinder (219).

Screw

down

the rod

(J)

to

push the sleeve

out.

See Fig

19-1.

Flg

19-1

Assembling the pump.

NOTE Use repair kit 222-588, and use all the kit parts,

for the best results. Parts included

in

the kit are

marked with an asterisk, (201

*),

in

the

text

and

drawings.

NOTE: Soak the packings in oil, and coat the rod and

inside of the cylinder with oil to prevent dam-

age during assembly..

NOTE: Alternate leather and plastic packings as

shown in Fig 1.8-3.

Be

sure the lips of the v-

packings face the direction shown. incorrect

installation damages the packings and resuits

in pump leakage.

1. Check the piston rod (224) and the inside of the sleeve

.

(218) for scoring or scratches. If these parts are dam-

2. Stack the piston packings

onto

the piston (222) as

aged, new packings will

not

seal properly.

shown in Fig 18-3 and Fig 19-2.

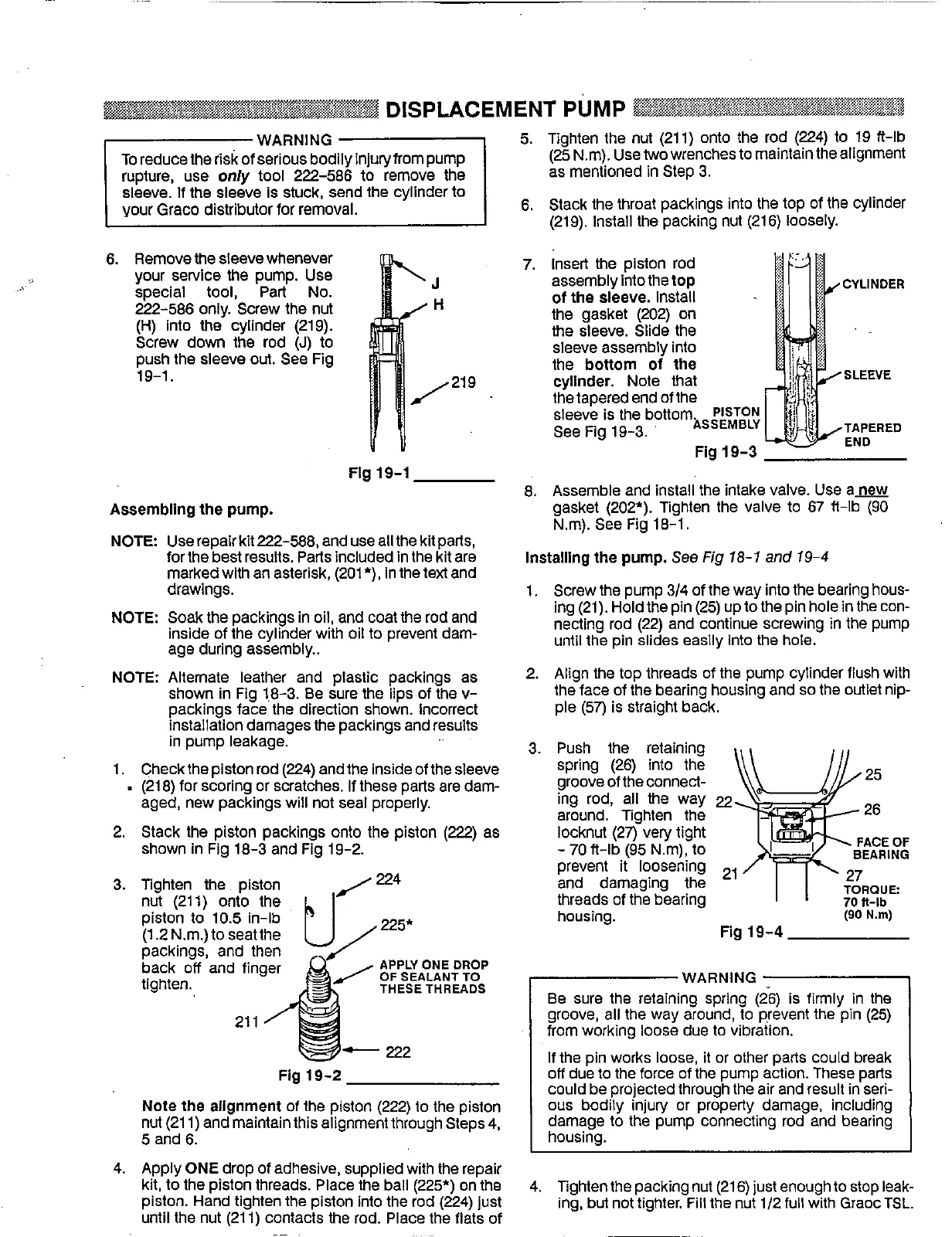

3.

Tighten the piston

nut (211)

onto

the

piston

to

10.5 in-lb

packings, and then

(1.2 N.m.)

to

seat the

tighten.

back

off

and finger

211

APPLY ONE

DROP

OF

SEALANT TO

THESETHREADS

Flg

19-2

Note the alignment of the piston (222) to the piston

5

and 6.

nut

(21 1) and maintain this alignment through Steps 4,

4. Apply ONE drop of adhesive, supplied with the repair

kit,

to

the piston threads. Place the ball (225')

on

the

piston. Hand tighten the piston into the rod (224) just

until the

nut

(21 1) contacts the rod. Place the flats of

~ ~~

7.

Insert the piston rod

assembly into thetop

CYLINDER

of

the sleeve. Install

the gasket (202)

on

the sleeve. Slide the

sleeve assembly

Into

the bottom of the

cylinder. Note that

the tapered end of the

sleeve is the bottom&y;;

See

Fig 19-3.

TAPERED

SLEEVE

Fig

19-3

END

8.

Assemble and install the intake valve. Use anew

gasket (202'). Tighten the valve

to

67

ff-lb

(90

Nm). See Fig 18-1.

installing the pump. See

Fig

18-1 and 19-4

1. Screw the pump 3/4 of the way into the bearing hous-

ing (21). Hold the pin (25) up to the pin hole in the con-

necting rod (22) and continue screwing

in

the pump

until the pin slides easily Into the hole.

2.

Align the top threads

of

the pump cylinder flush with

the face of the bearing housing and

so

the outlet nip-

ple

(57)

is straight back.

3.

Push the retaining

spring (26) into the

groove of the connect-

ing rod, all the way

around. Tighten the

locknut (27) very tight

prevent it loosening

and damaging the

threads of the bearing

housing.

-

70

ft-lb

(95

Nm),

to

Fig

19-4

WARNING

Be

sure the retaining spring

(26)

is firmly in the

groove, all the way around,

to

prevent the pin (25)

from working

loose

due

to

vibration.

If the pin works

loose,

it

or other parts could break

off

due

to

the force of the pump action. These parts

could be projected through the air and result in seri-

ous

bodily injury or property damage, including

damage to the pump connecting rod and bearing

housing.

4. Tighten the packing nut (21

6)

just

enough

to

stop leak-

ing, but

not

tighter. Fill the nut

1/2full

with GraocTSL.

~~~~

Loading...

Loading...