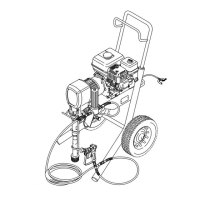

NOTE:

Refer

to

Fig 21-1 for this procedure.

1. Remove the front cover (23).

DO

NOT lose the thrust balls (20c and 19j) located

at each end of the gear cluster. The balls, which are

heaviiycoveredwithgrease,

usuallystayin the shaft

recesses, but they could be dislodged. If they are

caught between the gears and

not

removed, the

Placement Pump nipple

(57).

For the UDriaht carts

balls

are

not

in

place, the bearings wear

2.

Disconnect the

pump

Outlet

hose

(59)

from

the

dis-

balls will seriously damage the drive housing,

If

the

a,

remove the two

spring

clips (101,

103)

and the

drain hose (102) from the pump.

prematurely,

3. Remove the four screws (73) and lockwashers (74)

7.

Liberally apply bearing grease (20d, supplied)

to

the

from the bearing housing (21). gear cluster (1 8).

Be

sure the thrust balls (20c and 19j)

4. Lightlytap the back of the bearing housing with a plas-

are

in

place.

tic mallet. Pull the pump, bearing housing and con- 8. Place the bronze colored washer (20a) and then the

necting rod away from the drive housing as

one

assembly. from the big bearing

of

the drive housing (20). Alignthe

silver-colored washer (20b)

on

the shaft protruding

5.

Remove the

two

screws (24) and lockwashers (1

1).

the pinion housing and locating pins

(8).

gears and push the new drive housing straight Onto

Remove the four screws

(1

0)

and lockwashers (1 1).

6.

Lightlytap around the drive housing (20) with a plastic

9.

Starting at Step

5,

work backwards

to

reassemble the

mallet

to

loosen it from the pinion housing (19n).

sprayer. Or, move ahead

to

the

next

section

in

this

manual if further sewice

is

needed.

10

73

TORQUE TO

Fig

21-1

Loading...

Loading...