Startup

18 3A6400A

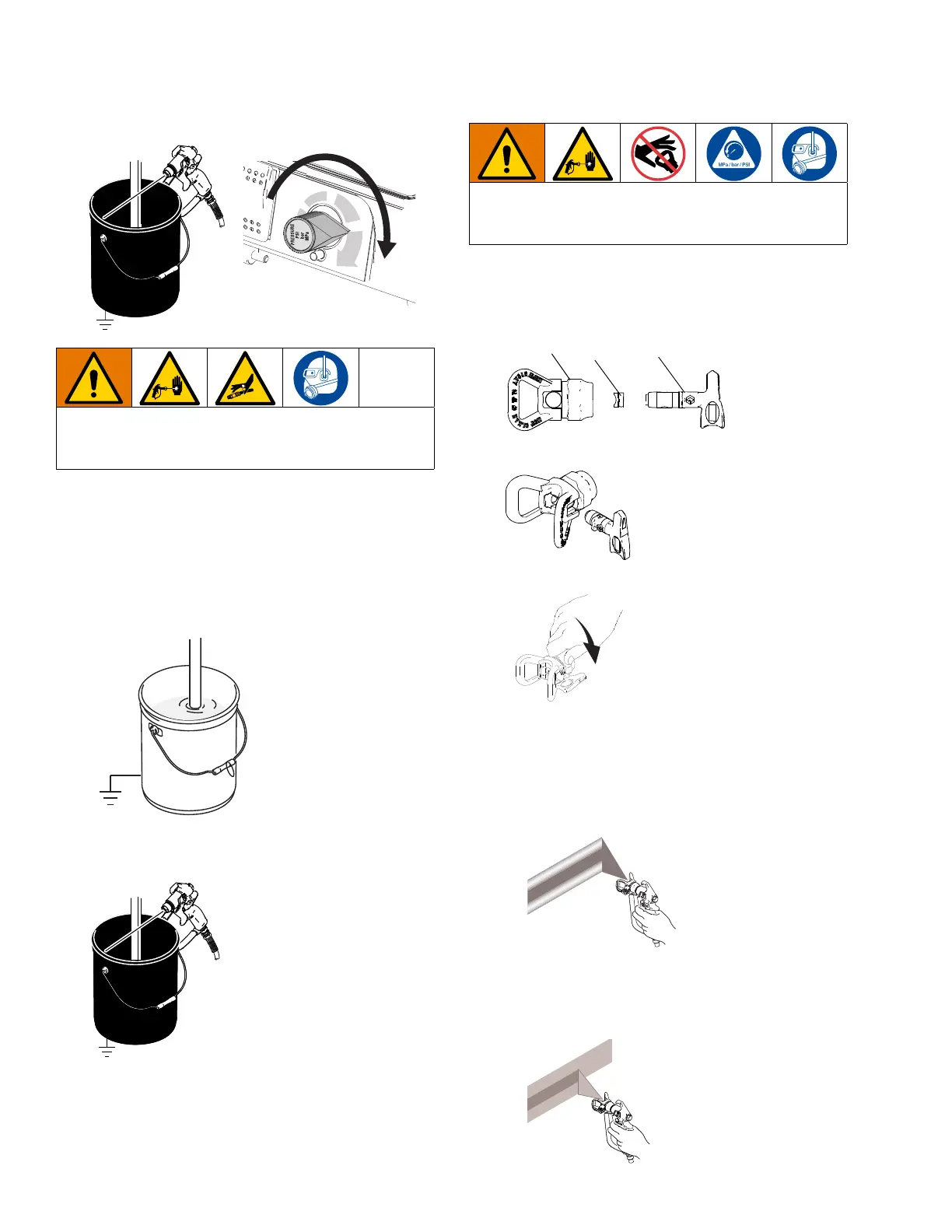

8. Hold gun against grounded metal flushing pail.

Trigger gun and increase fluid pressure slowly until

pump runs smoothly.

9. Inspect fittings for leaks. If leaks occur, turn sprayer

OFF immediately. Perform Pressure Relief

Procedure steps 1-3, page 13. Tighten leaky

fittings. Repeat Startup procedure steps 1 - 5. If no

leaks, continue to trigger gun until system is

thoroughly flushed. Proceed to step 6.

10. Place siphon tube in material pail.

11. Trigger gun again into flushing fluid pail until

material appears.

Switch Tip

™

Guard Assembly

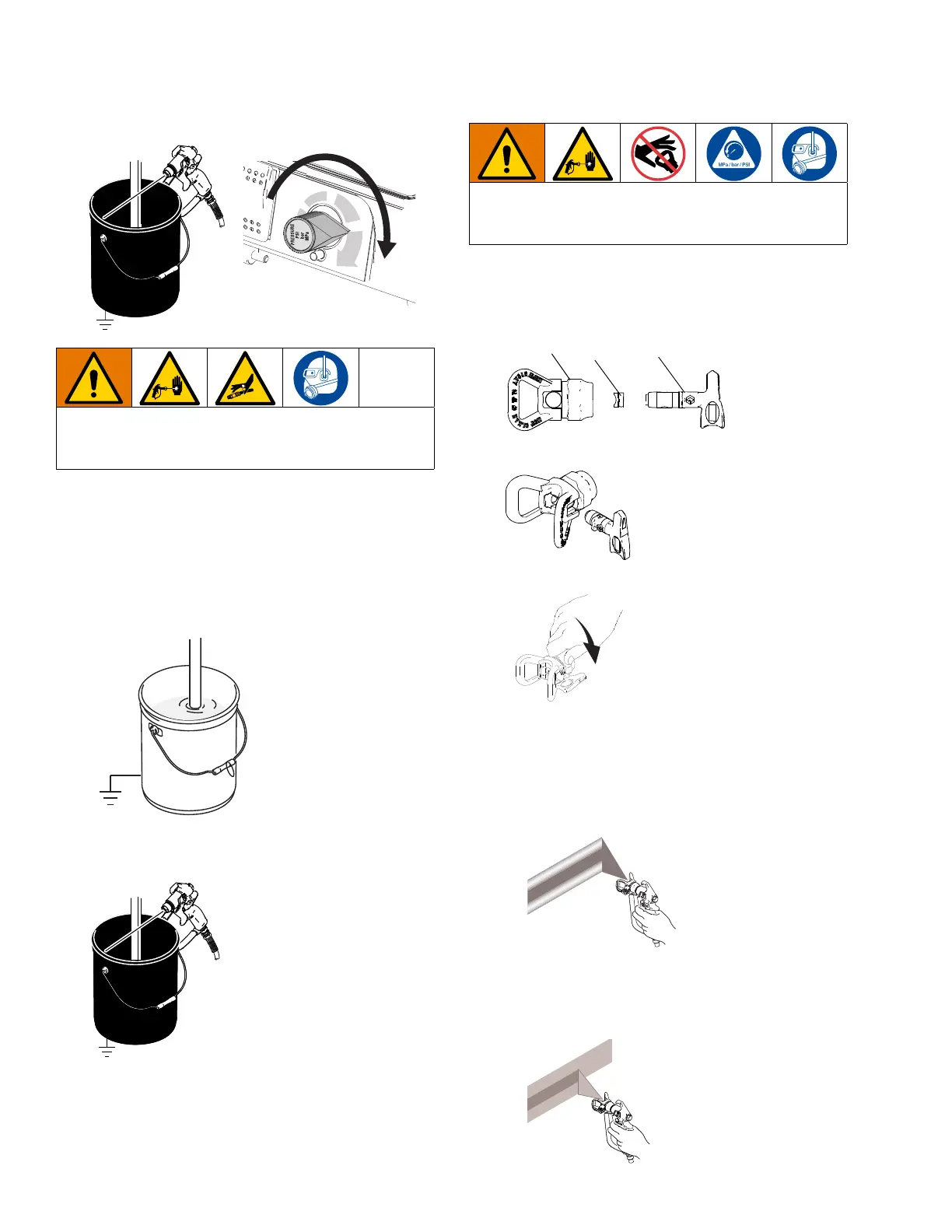

1. Perform Pressure Relief Procedure, page 13.

2. Engage gun trigger lock. Insert Switch Tip. Insert

seat and OneSeal

™

.

3. Insert Switch Tip.

4. Screw assembly onto gun. Tighten.

Spray

1. Spray test pattern. Increase pressure to eliminate

heavy edges. Use smaller tip size if pressure

adjustment can not eliminate heavy edges.

2. Hold gun perpendicular, 10-12 in. (25-30 cm) from

surface. Spray back and forth. Overlap by 50%.

Trigger gun after moving and release before

stopping.

High-pressure spray is able to inject toxins into the

body and cause serious bodily injury. Do not stop

leaks with hand or rag.

To avoid serious injury from skin injection do not put

your hand in front of the spray tip when installing or

removing the spray tip and tip guard.

Loading...

Loading...