308868 13

Pressure Control Transducer

Removal

1.

Relieve pressure; page 4.

2. Fig. 15. Remove five screws (307) and

cover (322).

3. Disconnect lead (E) from control board (302).

4. Remove three screws (319) and fluid filter (318)

from control plate (301). Carefully pull transducer

connector through rubber grommet (315).

5. Remove pressure control transducer (318z) and

packing o-ring (318aa) from filter housing (318a).

Installation

1. Fig. 15. Install packing o-ring (318aa) and pres-

sure control transducer (318z) in filter

housing (318a). Torque to 30–35 ft-lb.

2. Carefully feed transducer connector through

rubber grommet (315). Install fluid filter (318) on

control plate (301) with three screws (319).

3. Connect lead (E) to motor control board (302).

4. Install cover (322) with five screws (307).

Pressure Adjust Potentiometer

Removal

1.

Relieve pressure; page 4.

2. Fig. 15. Remove five screws (307) and

cover (322).

3. Disconnect lead (D) from control board (302).

4. Loosen set screws on potentiometer knob (313)

and remove knob, shaft nut, lockwasher (310) and

pressure adjust potentiometer (310).

5. Remove seal (311) from potentiometer (310).

Installation

1. Install seal (311) on potentiometer (310).

2. Fig. 15. Install pressure adjust potentiometer

(310), shaft nut, lockwasher (310) and potentiome-

ter knob (313).

a. Turn potentiometer shaft (310) clockwise to

internal stop. Assemble potentiometer knob

(313) to strike pin on plate (312) and have

bottom of knob clear plate by .040 to .060 in.

b. After adjustment of step a., tighten both set

screws in knob 1/4 to 3/8 turn after contact

with shaft.

3. Connect lead (D) to control board (302).

4. Install cover (322) with five screws (307).

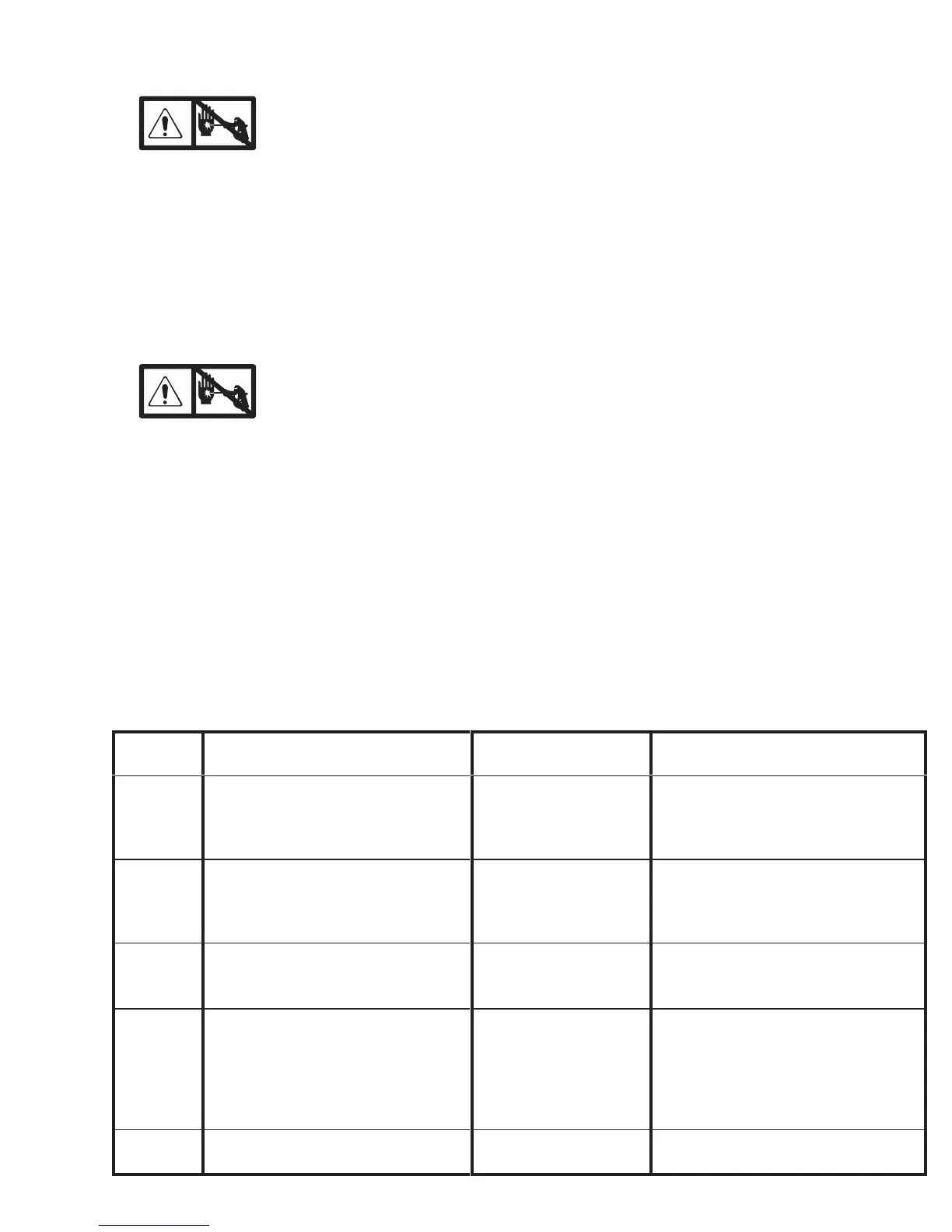

Control Board Diagnostics

1. Fig. 15. Remove five screws (307) and

cover (322).

2. Start sprayer.

3. Turn ON/OFF switch ON.

4. Observe LED operation and reference following

table:

LED

BLINKS

SPRAYER OPERATION INDICATES WHAT TO DO

Two times

repeatedly

Sprayer shuts down and LED contin-

ues to blink two times repeatedly

Run away pressure.

Pressure greater than

4500 psi (310 bar, 31

MPa).

1. Check pressure transducer con-

nection at control board

2. Replace pressure transducer

3. Replace control board

Three

times re-

peatedly

Sprayer shuts down and LED contin-

ues to blink three times repeatedly

Pressure transducer is

faulty or missing

1. Check pressure transducer con-

nection at control board

2. Replace pressure transducer

3. Replace control board

Four times

repeatedly

Sprayer shuts down and LED contin-

ues to blink four times repeatedly

Generator voltage is

low

1. Increase engine throttle

2. Check wiring connections

3. Service Honda engine alternator

Five times

repeatedly

Sprayer shuts down and LED contin-

ues to blink five times repeatedly

High clutch current 1. Check clutch 5-pin bulkhead con-

nector. Clean contacts.

2. Measure 1.2 0.2Ω

(GMax3900); 1.7 0.2Ω (GMax

5900) across clutch field at 70F

3. Replace clutch field assembly

Six times

repeatedly

Sprayer shuts down and LED contin-

ues to blink six times repeatedly

High clutch temperature Replace clutch armature and rotor

Loading...

Loading...