309205 17

Service

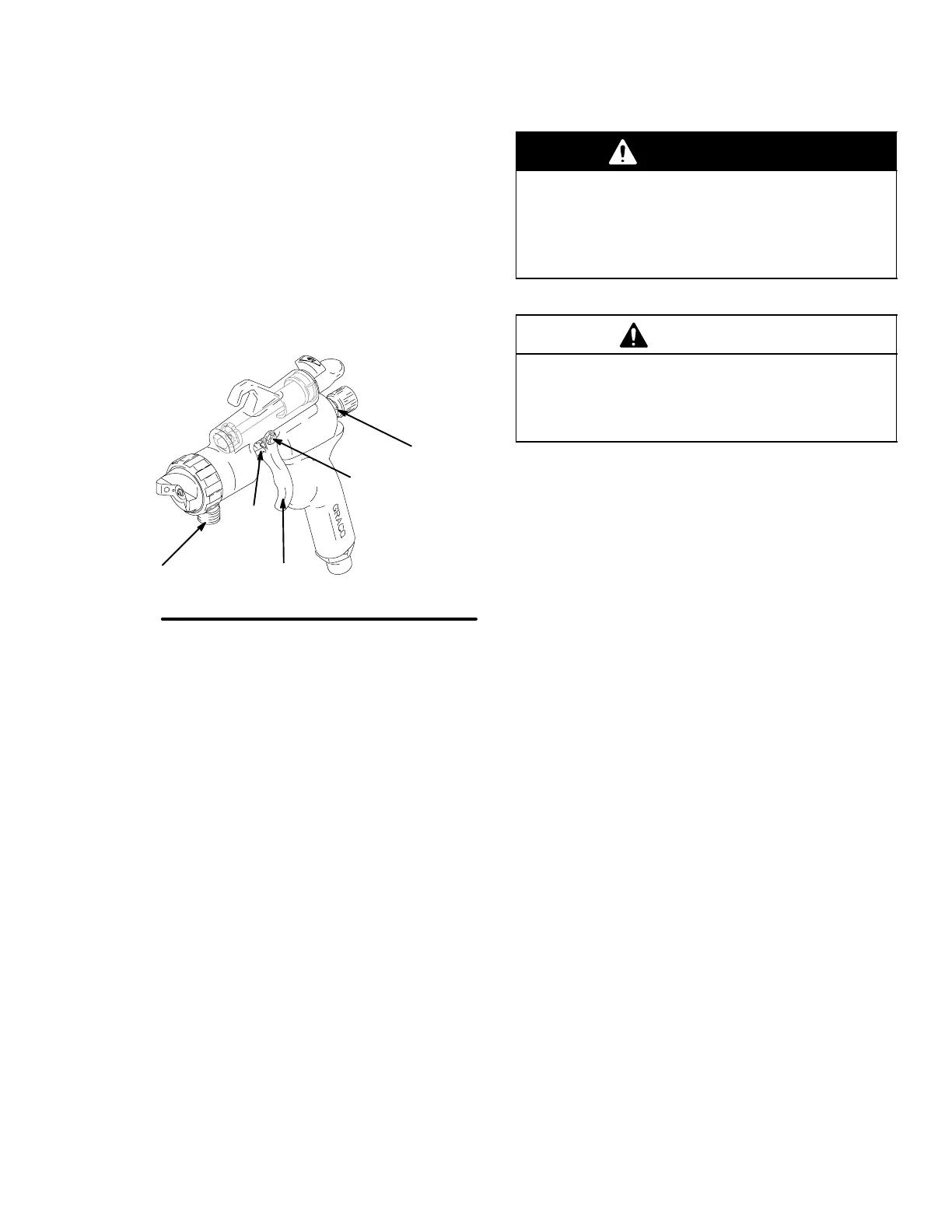

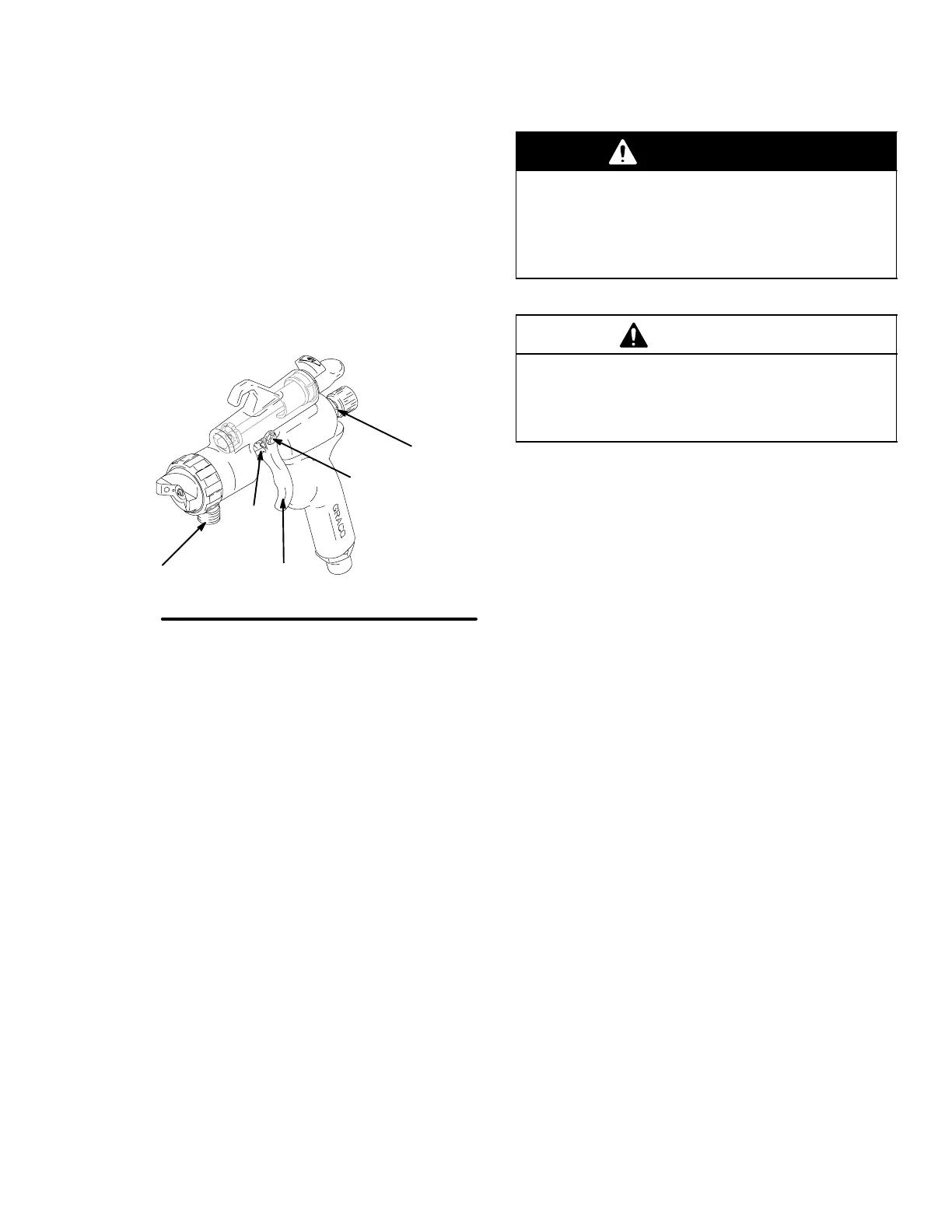

Lubricating the Spray Gun

After cleaning or servicing gun, lubricate parts

indicated in Fig. 23 with silicone-free spray gun

lubricant or similar material.

D All threaded areas (A)

D Trigger screws (B)

D Trigger axle (C)

D Fluid needle assembly (D) (see #16, Parts, page

22)

Fig. 23

B

A

TI0883

C

A

D

Replacing the Needle

WARNING

PRESSURIZED EQUIPMENT HAZARD

To reduce the risk of a serious injury, follow the

Pressure Relief Procedure on page 11 before

checking or repairing any part of the gun or sys-

tem.

1. Relieve the pressure.

CAUTION

Trigger the gun whenever you tighten or remove the

nozzle. This keeps the needle seat away from the

nozzle seating surface and prevents the seat from

being scratched.

2. Remove the fluid adjustment knob (21) and fluid

spring (23).

3. Pull the fluid needle assembly (16) out the back of

the gun.

4. Check the fluid needle (16) for damage or exces-

sive wear. Replace needle if necessary.

5. Insert the fluid needle assembly (16) into the back

of the gun.

6. Tighten the packing screw (8). The needle (16)

must move freely.

NOTE: To ensure proper alignment of the parts, follow

the next steps in the order they are given.

7. Lubricate and install the fluid needle (16).

8. Lubricate the fluid adjustment knob threads (21),

and install the fluid spring (23) and adjustment

knob.

9. Trigger the gun to test the needle movement. If the

needle does not return after the trigger is released

or is slow in returning, loosen the packing screw

(8) slightly until the needle returns freely.

10. Make sure the gun fluid packings are sealing

properly by spraying solvent at low pressure

before fully pressurizing the gun with the fluid to be

sprayed.

If the fluid packings leak, tighten the packing screw

(8) slightly and retest until the packings and needle

seal completely.

Loading...

Loading...