MAINTENANCE

1

Check

the

packing nut/wet–cup daily

.

Relieve the

pressure.

Keep the packing nut/wet–cup 1/3 full with

TSL at all times to help prevent fluid buildup on the

piston

rod and premature wear of packings.

T

ighten

the packing nut just enough to stop leakage. Over-

tightening

may

cause binding and excessive packing

wear.

Use a 1/4 inch diameter rod to adjust the nut.

2

Clean

the fluid filter often

and whenever the spray

-

er is stored. First relieve pressure. See manual

307–273

for the cleaning procedure.

3 For very short shutoff periods, leave the suction

tube in the paint, relieve pressure, and clean the

spray

tip.

4 At the end of each work day , flush the sprayer

and relieve pressure. Leave the pump and hoses

filled

with mineral spirits to help prevent pump corro

-

sion and freezing. See FLUSHING GUIDELINES,

page

10.

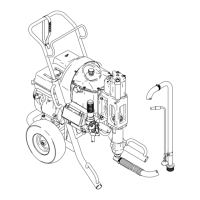

Fig 7

PLUG

SPOOL

5 If the pump stalls at the top of its stroke, relieve

fluid

pressure, remove the plug from the top of the hy

-

draulic motor

, and push the spool all the way down.

See

Fig 7. Replace the plug and

restart the sprayer

.

NOTE: Relieving pressure whenever you are not using

the sprayer helps prevent the pump stalling at

the

top of its stroke.

6

Coil

the hose and hang it on the

hose rack

when

storing

it, even for overnight, to help protect the hose

from

kinking, abrasion, coupling damage, etc.

7 Check the hydraulic fluid level occasionally. Add

fluid

as necessary to keep the fluid level between the

ADD

and FULL marks on the dipstick. See page 9.

8 Change

the hydraulic fluid

every 2000 hours of

op

-

eration or 12 months, whichever comes first. Also

clean

the hydraulic pump intake filter and replace the

disposable

filter in the return line. First

, relieve pres

-

sure. then remove the sprayer shield. Refer to Re-

placing

the Electric Motor

on page 17 to get at the

filters. Remove the old hydraulic fluid and clean the

sump.

9 Periodically, or if the electric motor is overheating,

unplug the sprayer , relieve pressure, remove the

shield,

and

clean all paint and dirt from the shield, fan

blades,

motor and cooling fins.

10 To transport the sprayer, empty the wet-cup, or re-

duce

the level of Throat Seal Liquid to 1/3 full or less

and

stuf

f

a rag into the wet-cup. Load the sprayer as

shown in Fig 8. To avoid leakage of hydraulic fluid,

never

lay the sprayer on its side.

Fig 8

LOAD

AS SHOWN.

NEVER LAY SPRA

YER ON SIDE.

TROUBLESHOOTING GUIDE

WARNING

To

reduce the risk of serious bodily injury

, including fluid injection, injury from splashing fluid

or solvent in the eyes

or

on the skin, moving parts

or electric shock, always follow the

Pressure Relief Procedure

on page 1

1 whenever

you shut off the sprayer, when checking or servicing any part of the spray system, when installing, cleaning or

changing

spray tips, and whenever you stop spraying.

Check everything in the guide before disassembling the sprayer

.

PROBLEM CAUSE SOLUTION

Building

circuit breaker opens

Check all electrical wiring for damaged

insulation.

Replace any damaged wiring.

Check for other electrical appliances on

circuit.

Shutdown other electrical appliances on

circuit.

Loading...

Loading...