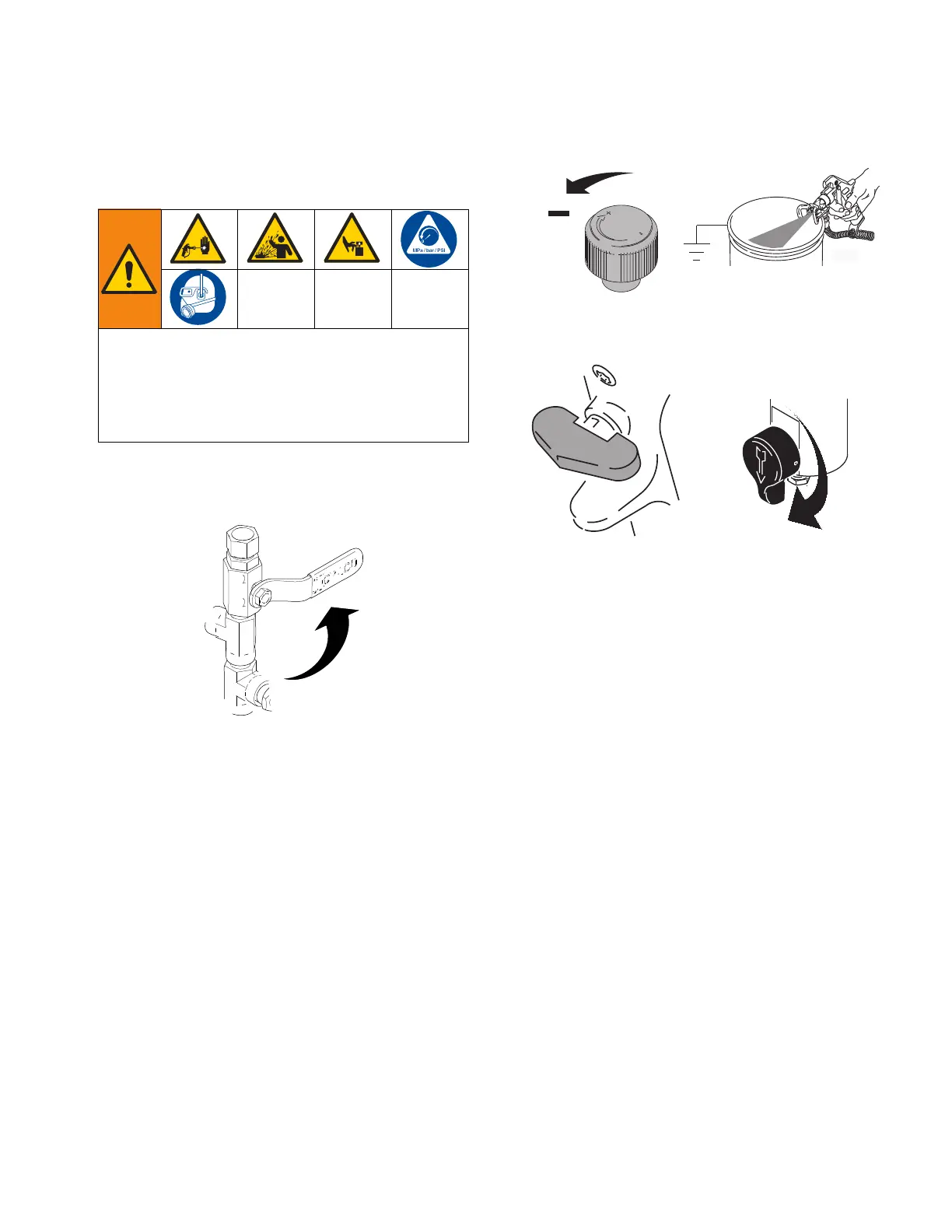

Pressure Relief Procedure

3A6981C Repair 3

Pressure Relief

Procedure

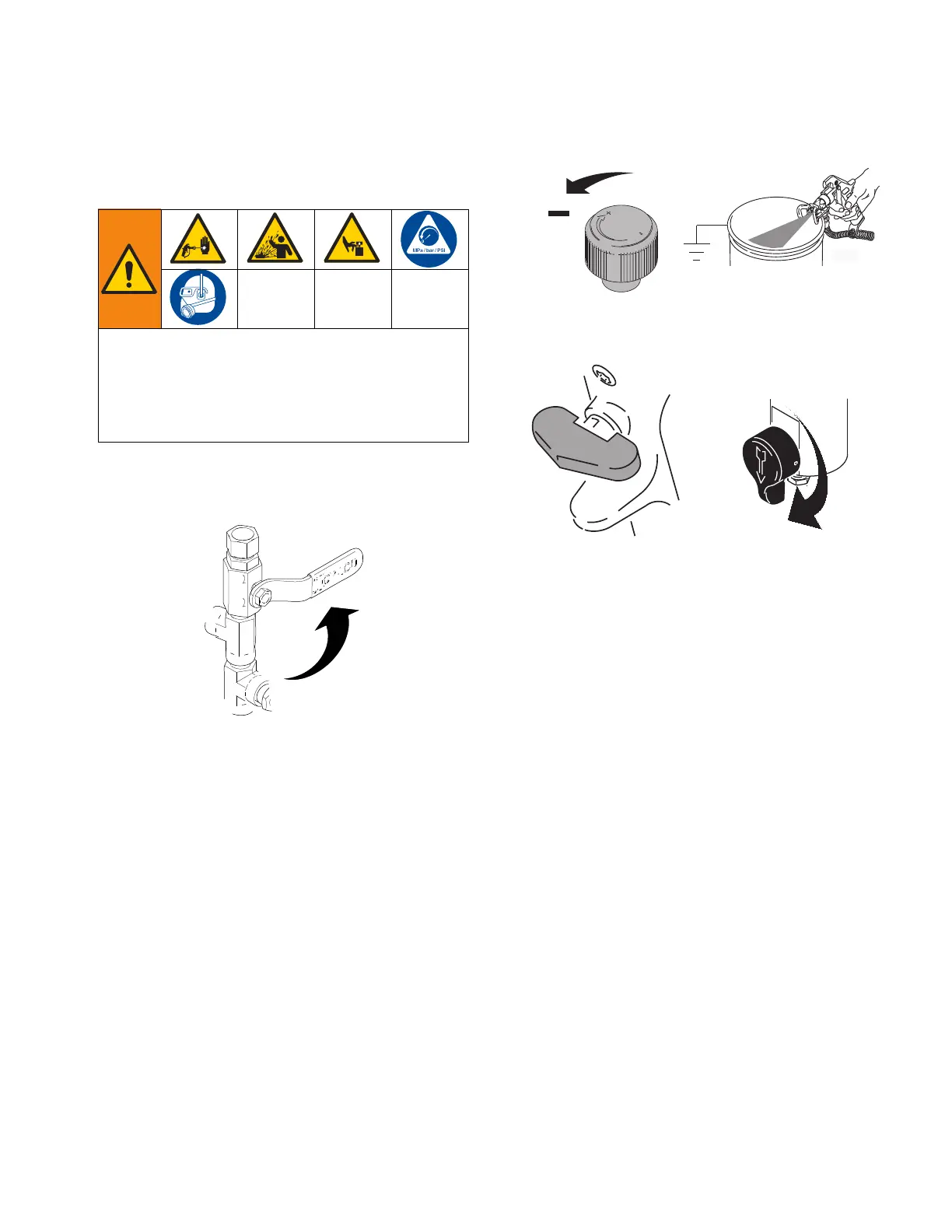

1. Set pump valve(s) to OFF (250SPS has one pump

valve; 250DC has two pump valves). Turn engine

OFF.

2. Turn pressure control to lowest setting. Trigger all

guns to relieve pressure.

3. Engage all gun trigger locks. Turn prime valve(s)

down (250

SPS

has one prime valve; 250

DC

has two

prime valves).

4. If you suspect the spray tip or hose is clogged or

that pressure has not been fully relieved:

a. VERY SLOWLY loosen the tip guard retaining

nut or the hose end coupling to relieve pressure

gradually.

b. Loosen the nut or coupling completely.

c. Clear the obstruction in the hose or tip

.

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury

from pressurized fluid, such as skin injection, splash-

ing fluid and moving parts, follow the Pressure Relief

Procedure when you stop dispensing and before

cleaning, checking, or servicing the equipment.

PAINT

ti3305a

Loading...

Loading...