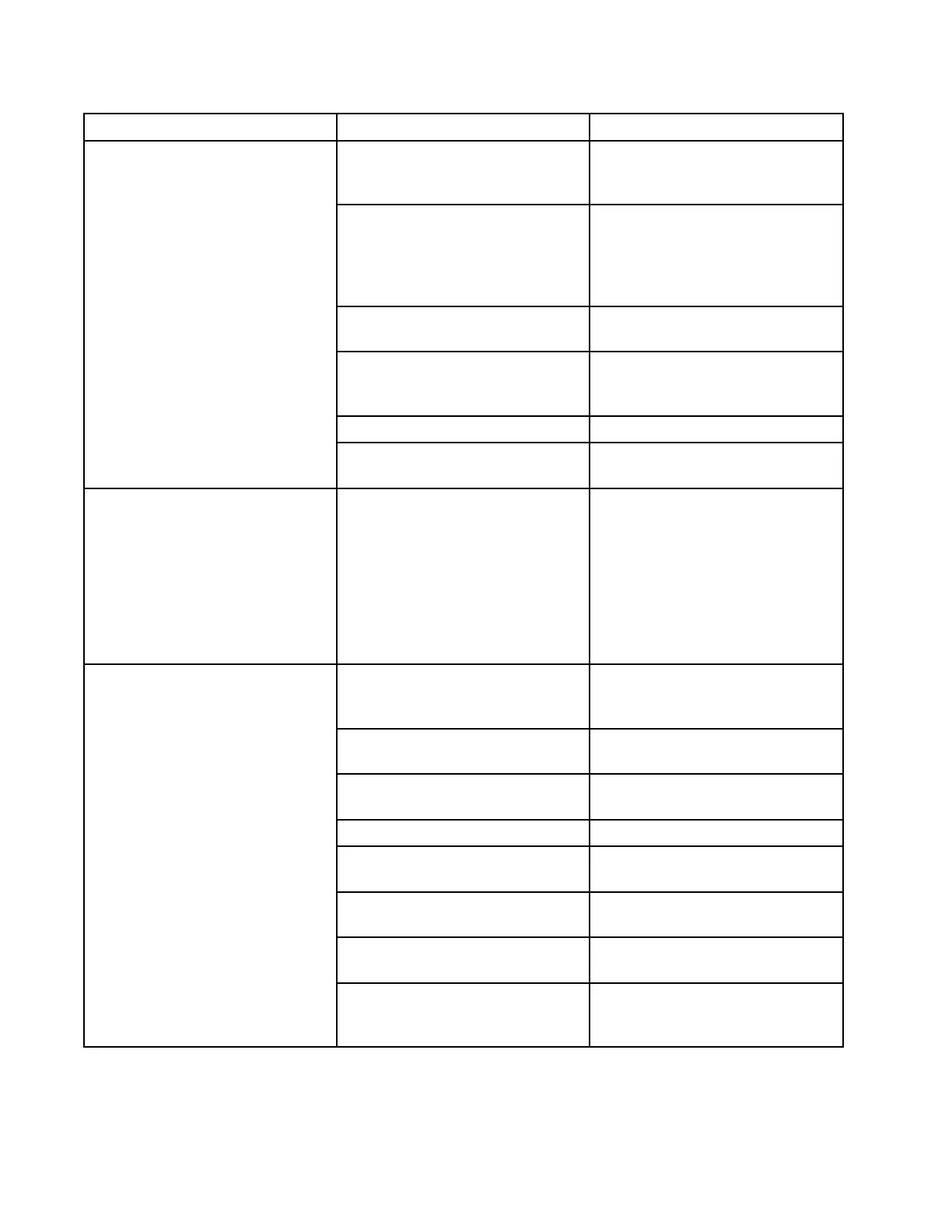

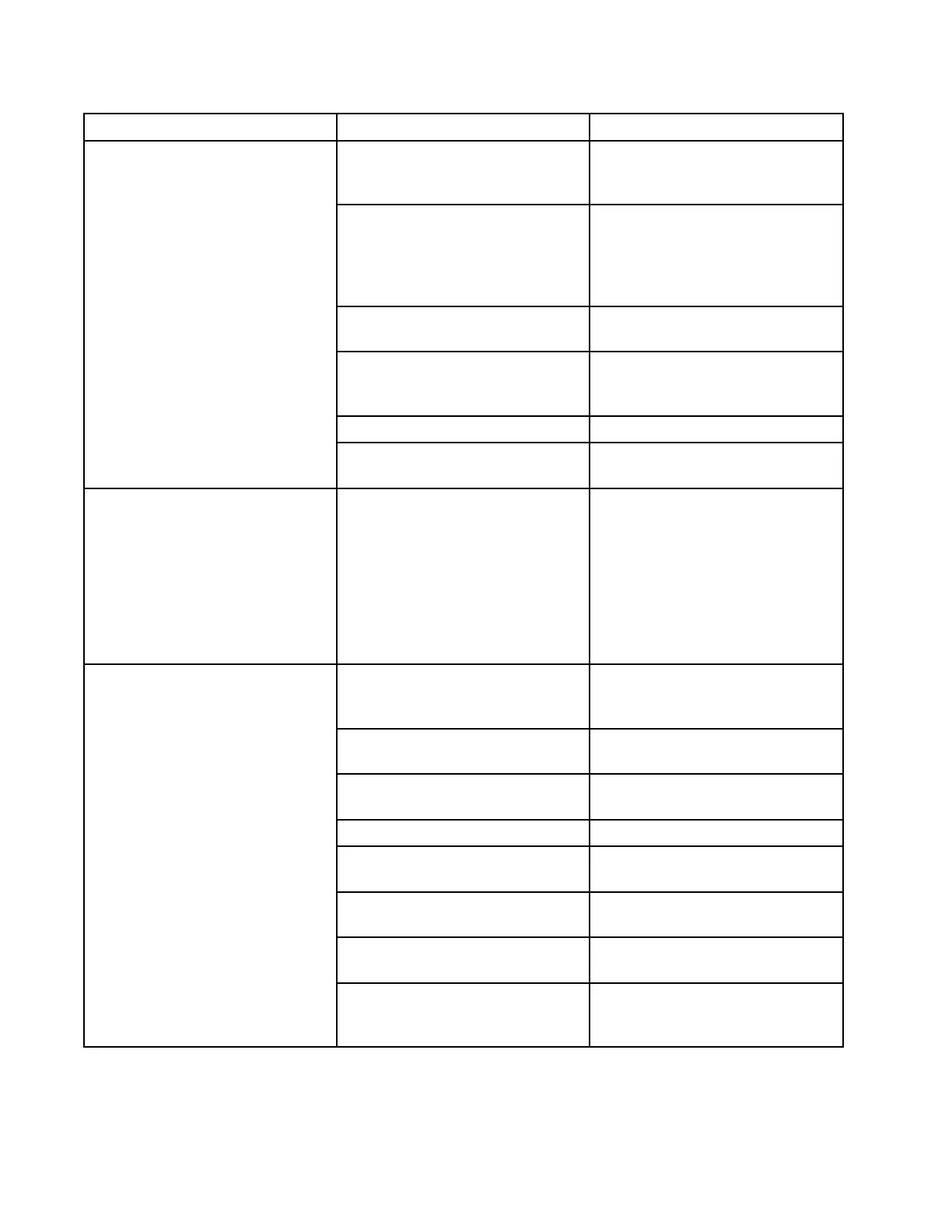

Troubleshootin

g

Problem

Cause Solution

FTS failed. Check FTS, see

Repair Fluid

Temperature S

ensor (FTS), page

74.

FTS not installed correctly. FTS should be installed close to

end of hose in same environment

as gun. Verify FTS installation,

see Repair Fluid Temperature

Sensor (FTS), page 74.

Loose hose e

lectrical connections.

Check connections. Repair as

necessary.

Circuit b

reakers tripped.

Reset bre

akers (CB01 ), see

Repair Ci

rcuit Breaker Module,

page 63.

Hose zone not turned on. Turn on hose heat zone.

Hose does not heat.

A and B temperature setpoints too

low.

Check. I

ncrease if necessary.

Hoses ne

ar Reactor are warm, but

hoses d

ownstream are cold.

Shorted connection or failed hose

heating element.

With power off, check the hose

resistance with and without the

whip hose attached. With the

whip hose attached, the reading

should be less than 3 ohm. With-

out the whip hose attached, the

reading should be OL (open loop).

See Check Hose Heat Power

Connectors, page 71.

A and B temperature setpoints too

low.

Increase A and B setpoints. Hose

designed to maintain temperature,

not increase temperature.

Hose

temperature setpoint too

low.

Check. Increase if necessary to

maintain heat.

Flow too high. Use smaller mix chamber.

Decrease pressure.

Low current; FTS not installed. Install FTS, see operation manual.

Hose heat zone not turned on long

enough to reach setpoint.

Allow hose to heat up, or preheat

fluid.

L

oose hose electrical connections.

Check connections. Repair as

necessary.

Ambient temperature is to low Relocate hoses to a warmer area

or increase A and B setpoints.

Low hose heat.

If Hose Resistance Mode is

enabled, the calibration factor may

be inaccurate.

Re-calibrate the hose. Follow the

Calibration Procedure, page 75.

46 333024N

Loading...

Loading...