Setup

Connect Connect

Connect

Power Power

Power

Allelectricalwiringmustbedonebyaqualied

electricianandcomplywithalllocalcodesand

regulations.

1.Turnmainpowerswitch(MP)OFF.

2.Openelectricalenclosuredoor.

NOTE: NOTE:

NOTE:

Terminaljumpersarelocatedinsidethe

electricalenclosuredoorifequipped.

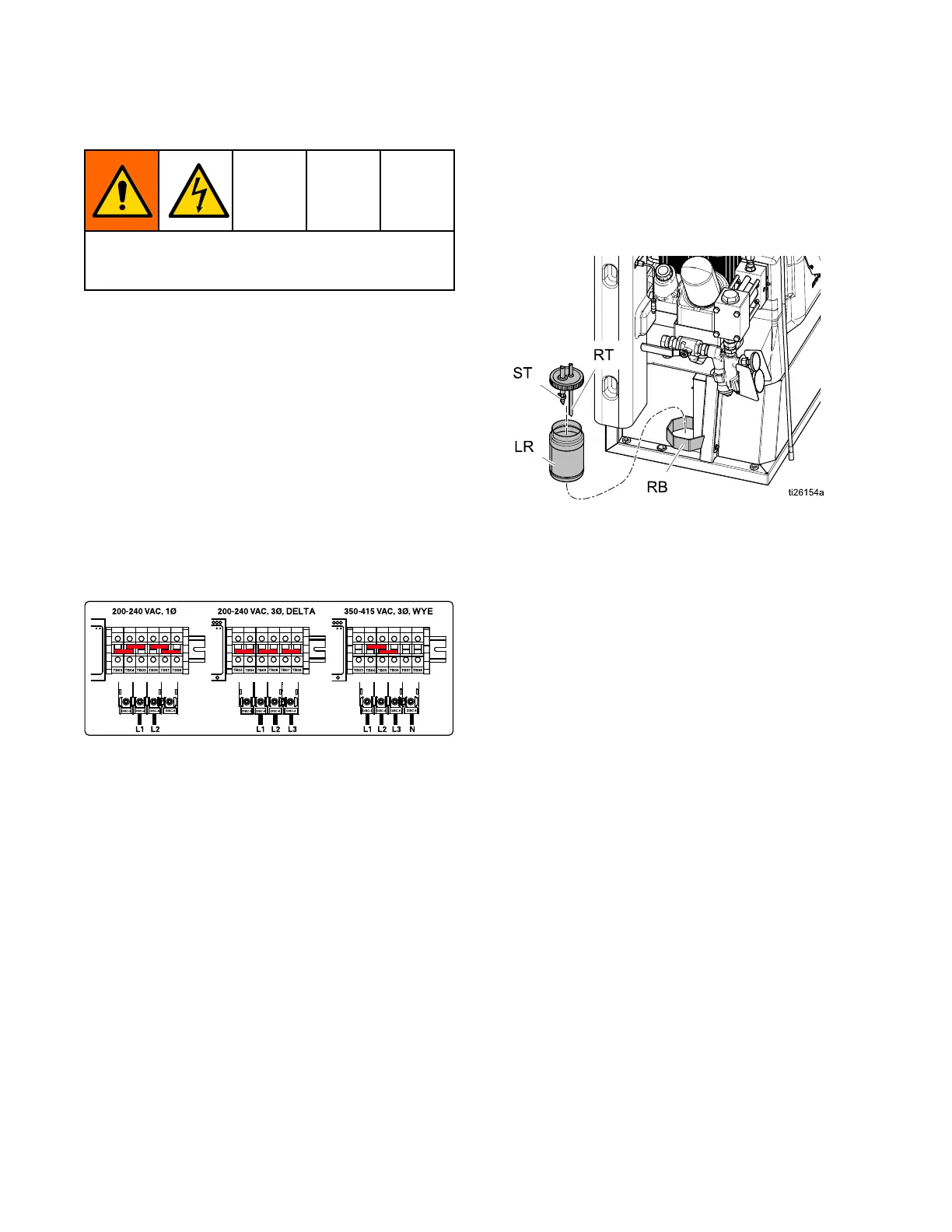

3.Installsuppliedterminaljumpersinthepositions

showninimageforthepowersourceused(H-30

andH-XP2modelsonly).

4.Routepowercablethroughstrainrelief(EC)in

electricalenclosure.

5.Connectincomingpowerwiresasshownin

image.Gentlypullonallconnectionstoverify

theyareproperlysecured.

6.Verifyallitemsareconnectedproperlyasshown

inimagethencloseelectricalenclosuredoor.

SeeModels,page9forReactorpower

requirements.

NOTE: NOTE:

NOTE:

350–415VACsystemsarenotdesignedto

operatefrom480VACpowersource.

Lubrication Lubrication

Lubrication

System System

System

Setup Setup

Setup

Component Component

Component

A A

A

(ISO) (ISO)

(ISO)

Pump: Pump:

Pump:

FillISOlubereservoir

(LR)withGracoThroatSealLiquid(TSL),part

206995(supplied).

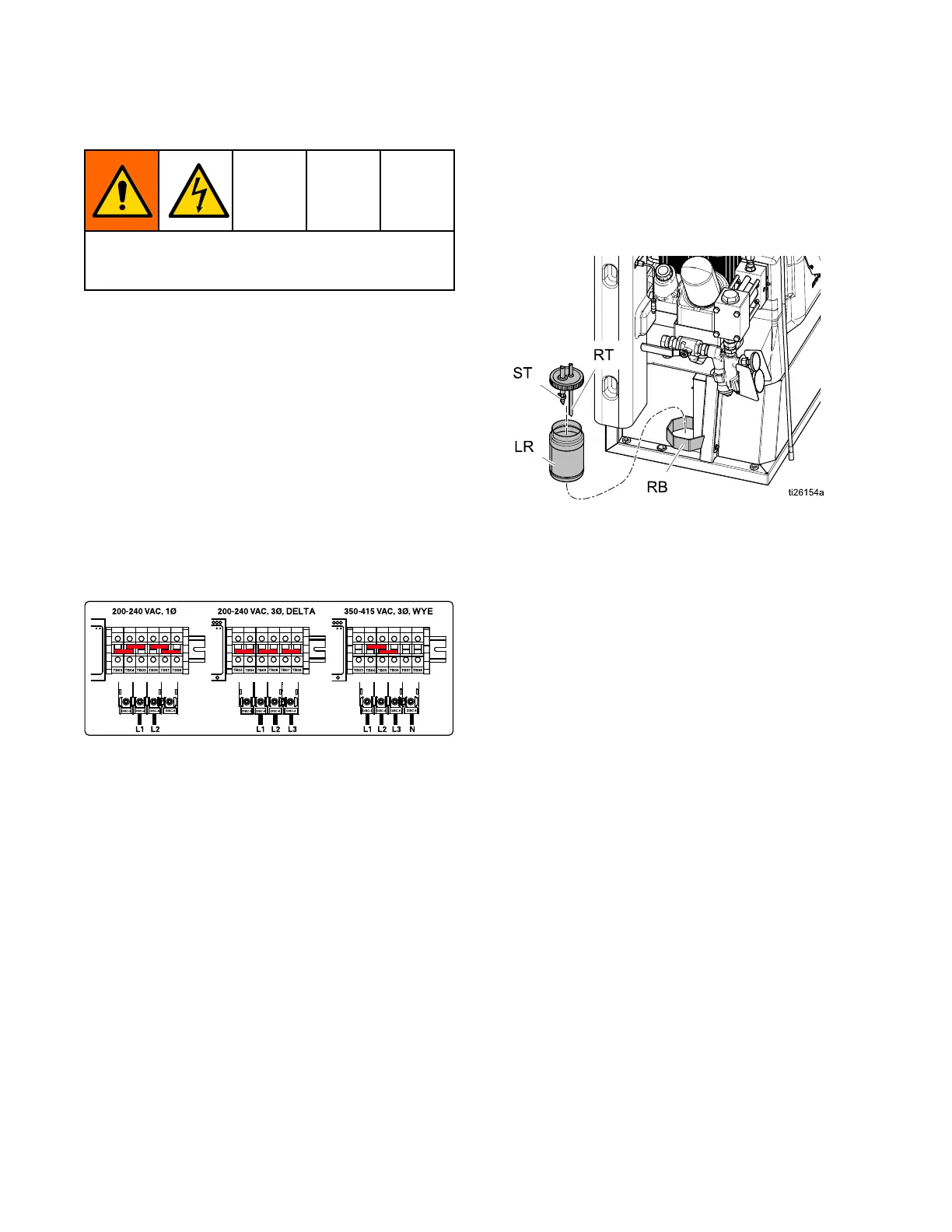

1.Liftthelubricantreservoir(LR)outofthebracket

(RB)andremovethecontainerfromthecap.

2.Fillwithfreshlubricant.Threadthereservoironto

thecapassemblyandplaceitinthebracket(RB).

3.Pushthelargerdiametersupplytube(ST)

approximately1/3ofthewayintothereservoir.

4.Pushthesmallerdiameterreturntube(RT)into

thereservoiruntilitreachesthebottom.

NOTE: NOTE:

NOTE:

Thereturn(RT)mustreachthebottomof

thereservoirtoensurethatisocyanatecrystals

willsettletothebottomandnotbesiphonedinto

thesupplytube(ST)andreturnedtothepump.

5.Thelubricationisreadyforoperation.Nopriming

isrequired.

32 334945J

Loading...

Loading...